Flue structure and installation method of new economizer

An economizer and flue technology, which is applied to combustion methods, exhaust gas devices, feed water heaters, etc., can solve the problems of cumbersome flue maintenance, inability to meet new structural design requirements, and inability to implement inclined flue suspension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

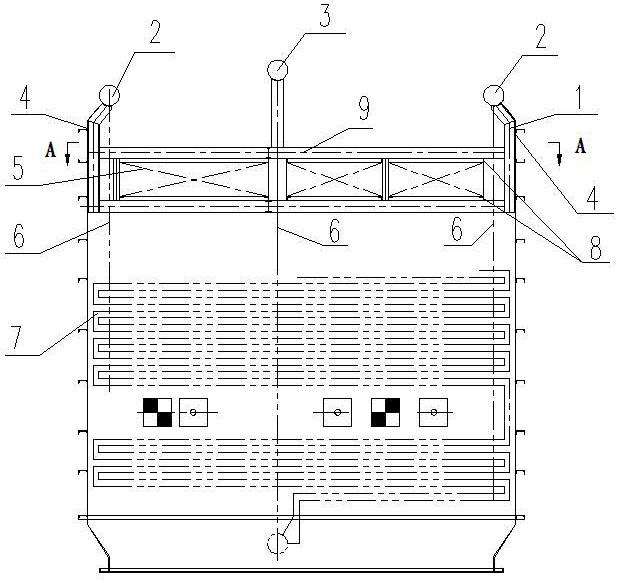

[0025] A new economizer flue structure, its composition includes: flue structure, the flue structure includes truss A1, truss B9, guard plate 4, angle steel slideway 8, the truss A and the wall header 2 Fix by welding and design the inclination angle a, the angle a is 0~45°, the side of the truss A is equipped with guard plates, the truss A and the truss B form an integral frame structure in the flue , the position of the baffle plate 5 of the truss A is provided with an angle steel that runs through the width direction of the flue, and the angle steel is welded on the inner side of the truss A and the guard plate as the support frame of the baffle plate, so The above-mentioned baffle is placed on the angle steel of the truss A, and the above-mentioned angle steel is the angle steel slideway when the boiler shutdown maintenance needs to draw out the baffle.

Embodiment 2

[0027] According to the new economizer flue structure described in Embodiment 1, the middle part of the truss A is equipped with a partition wall header 3, the number of the truss A is one group and the distance between them is β, and the distance β is 2m-3m.

Embodiment 3

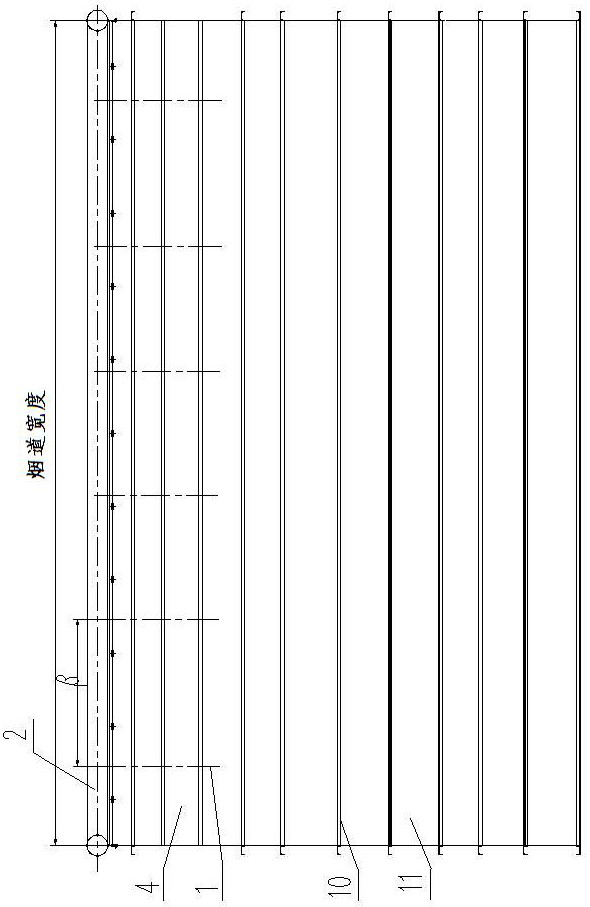

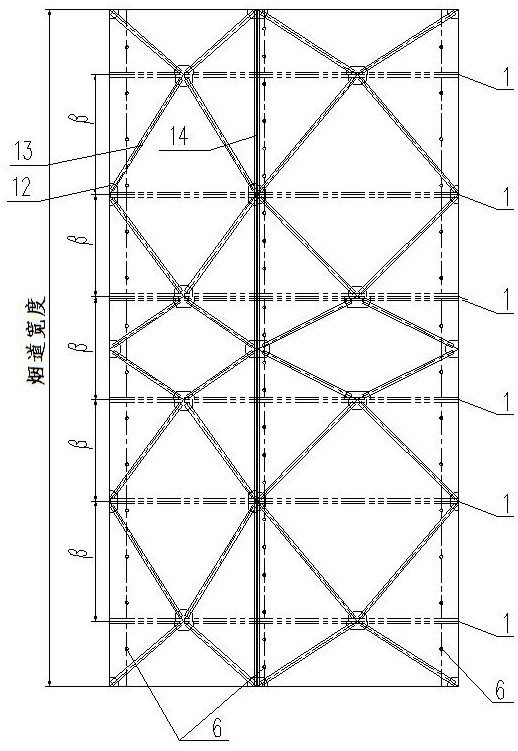

[0029] According to the novel economizer flue structure described in Example 2, the guard plate includes a set of section steel 10, steel plates 11 are welded between the section steel, the truss B includes I-beam 14, and the The I-beams are respectively connected to the steel pipes 13 through the connecting plates 12, the trusses A are respectively connected to the steel pipes through the connecting plates, and the steel pipes are arranged in a herringbone shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com