Control method for under-cooling and slush-freezing storage and refrigerator

A supercooling and semi-freezing technology, which is applied in cooling fluid circulation devices, food preservation, household refrigeration devices, etc., can solve the problems of easily punctured food cells, slow crystallization, and small thermal conductivity of food, so as to avoid the loss of nutrients, Realize the effect of supercooled semi-frozen storage and prolong the fresh-keeping period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a supercooled semi-frozen storage refrigerator, including:

[0038] The storage compartment has a supercooling and semi-freezing effect on the stored items;

[0039] The supercooling release device has the function of releasing the supercooled state of the stored items;

[0040] Preferably, the supercooling release device is a mechanical physical oscillator, which is composed of an electromagnet, a spring and a tray. The electromagnet and the spring drive the tray to vibrate to vibrate the stored items, and the applied oscillation frequency ranges from 50Hz to 60Hz;

[0041] The temperature detection unit has the function of real-time temperature detection;

[0042] The timing unit has the function of setting and monitoring the duration.

[0043] Preferably, the temperature detection unit includes a temperature sensor A and a temperature sensor B, wherein the temperature sensor A is used to detect the temperature of the stored items, and the t...

Embodiment 2

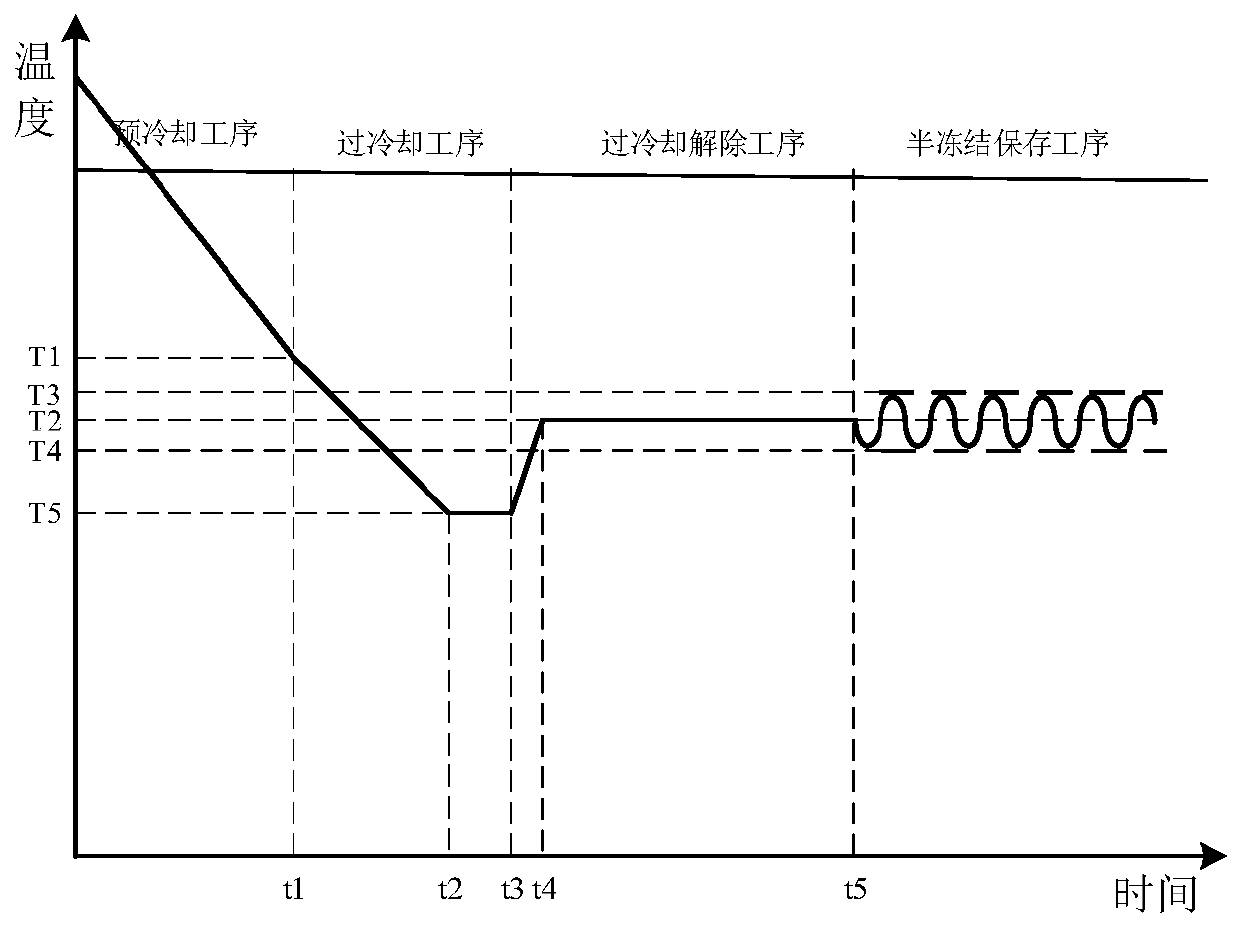

[0049] Attached below figure 1 The content of the specific embodiment in the present invention is described in detail: a kind of control method of subcooling semi-frozen storage, comprises the steps:

[0050] The temperature sensor A is used to detect the temperature of the stored items put into the storage compartment, and if it is detected that the temperature of the stored items is higher than the first temperature T1, the pre-cooling process is performed on the stored items; if the temperature of the stored items is detected to be equal to or lower than the first temperature T1 The temperature T1 is to perform a supercooling process on the stored items. In this implementation, it is preferred to perform a pre-cooling process on the stored items first.

[0051] In the pre-cooling process, the preset cooling target of the storage compartment is the first temperature T1, the preset duration of the pre-cooling process is t1, the timing unit starts timing, and the control unit ...

Embodiment 3

[0068] This embodiment provides another control method for supercooled and semi-frozen storage. Compared with Embodiment 2, this embodiment exchanges the sequence of heating operation and cooling operation in the semi-frozen storage process, that is, the storage compartment is first Heating operation, then cooling operation, and then cycle accordingly, the rest are the same as in Example 2, and will not be repeated here.

[0069] In summary, the present invention realizes semi-frozen storage of stored items near the freezing point by implementing the supercooling process, supercooling release process, and semi-frozen preservation process on the stored items, without complicated control, and the realization is relatively simple, which can effectively solve the problem of consumption For the short-term storage and preservation of fruits, vegetables, meat and other stored items, it also avoids the loss of nutrition and flavor loss caused by freezing of stored items, and can well m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com