A multi-strand wire core winding mechanism

A winding mechanism and multi-strand wire technology, applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problems of inability to detect the degree of twisting of the core, excessive twisting of the core, and the inability of continuous processing of the core. , to achieve the effect of avoiding excessive twisting and breaking, improving efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

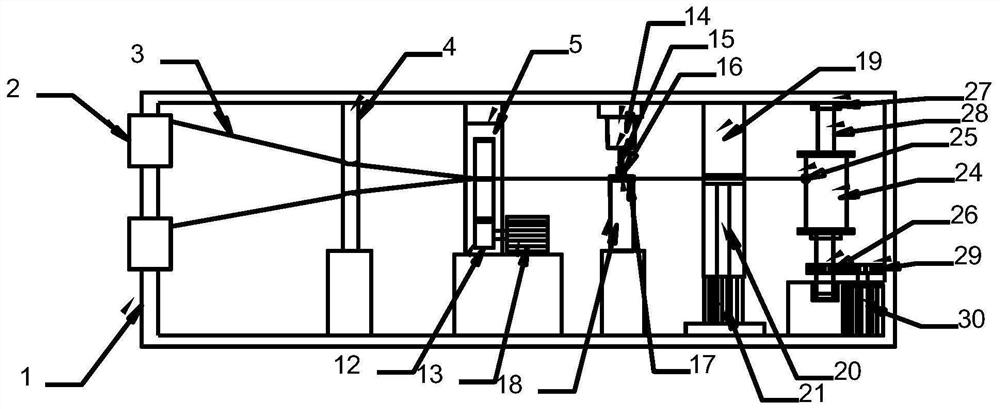

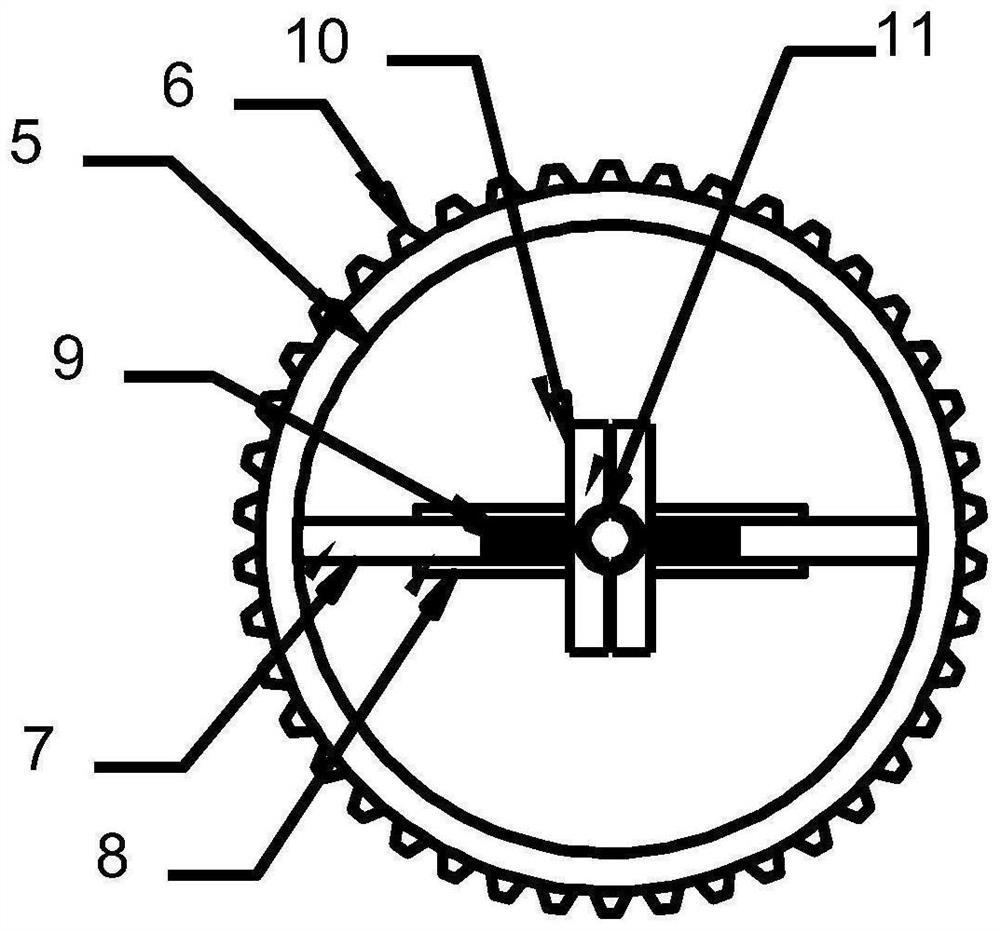

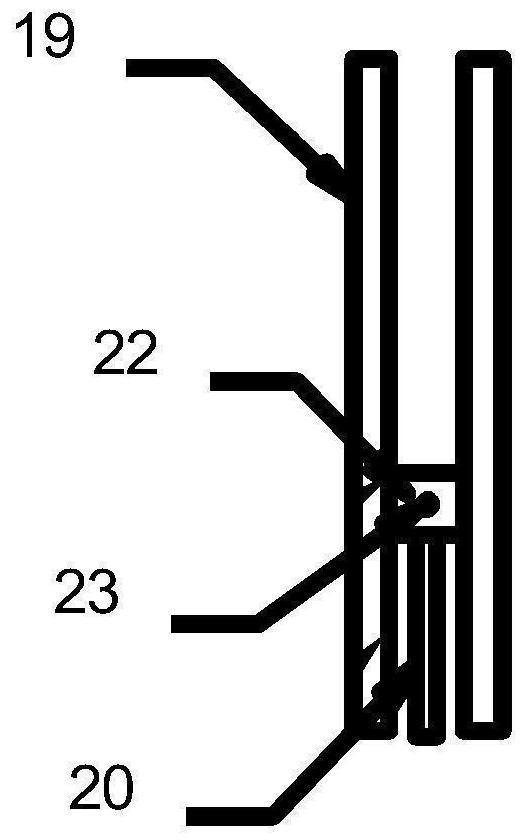

[0025] see Figure 1~5 , in an embodiment of the present invention, a multi-strand wire core winding mechanism includes a frame 1, a winding ring 5 and a drum 24, a wire core barrel 2 is installed on the left side of the frame 1, and a wire core barrel 2 is provided with a wire Core 3, the right side of the wire core 3 cylinder is provided with a wire fixing plate 4, the middle of the wire fixing plate 4 is provided with a wire core hole, and the edge of the wire core hole is arc-shaped; the right side of the wire fixing plate 4 is provided with a winding ring 5, and the winding A gear ring 6 is installed on the outer side of the ring 5, a long rod 7 is installed on the inner side of the winding ring 5, the top of the long rod 7 is connected to a spring 9, and a cylinder 8 is installed on the outer side of the spring 9, and the cylinder 8 is connected to the wire pressing plate 10, and the wire pressing plate 10 A rubber pad 11 is installed on the top, and one side of the pres...

Embodiment 2

[0028] see Figure 6 , in an embodiment of the present invention, a multi-strand wire core winding mechanism includes a frame 1, a winding ring 5 and a drum 24, a wire core barrel 2 is installed on the left side of the frame 1, and a wire core barrel 2 is provided with a wire Core 3, the winding ring 5 is arranged on the right side of the wire core 3 cylinder, the wire fixing ring 31 is installed on the left side of the winding ring 5, and the wire fixing ring 31 is installed on the fixing frame outside the winding ring 5, which reduces the processing cost , the wire cores 3 can also be collected, the distance between multiple wire cores 3 can be reduced, and it is convenient to wind the wire cores 3 . Other structures in this embodiment are the same as those in Embodiment 1.

[0029] The working principle of the present invention is:

[0030] A multi-strand wire core winding mechanism in which the wire fixing plate 4 collects the wire cores 3, reduces the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com