A compact jet cooling system

A cooling system, compact technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of temperature and volume limitations, high consumption and low efficiency, poor adaptability, etc., to achieve a wide temperature range, reduce Contact thermal resistance, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

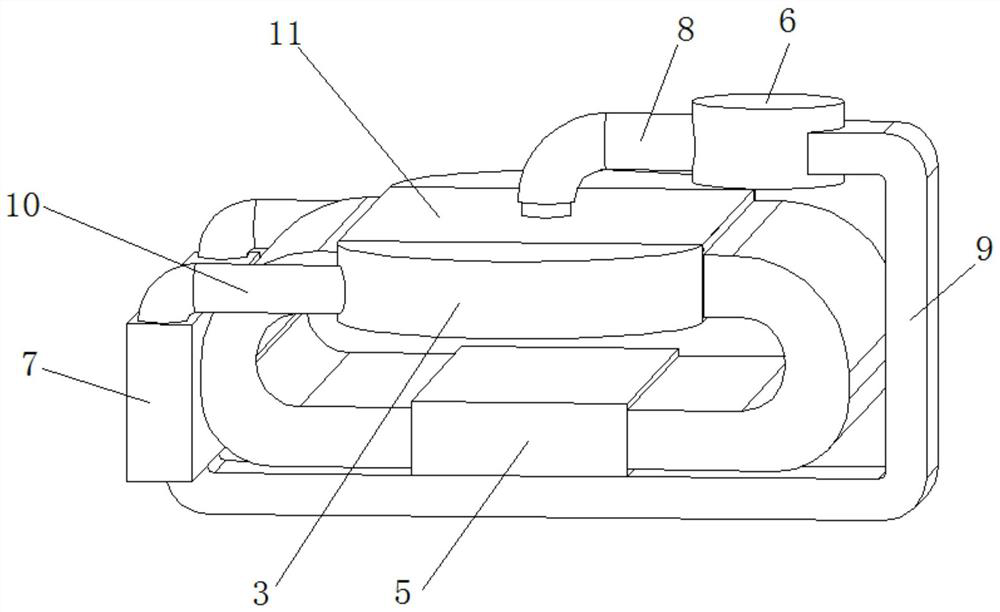

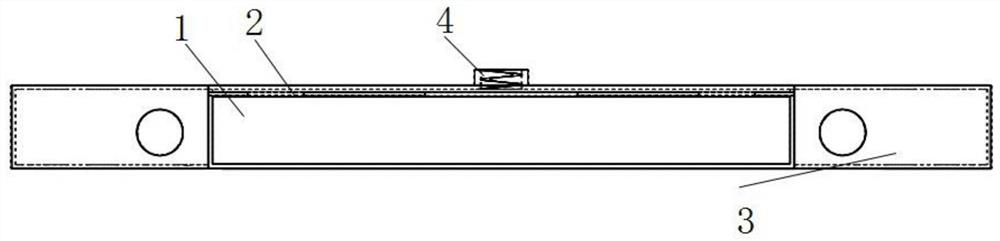

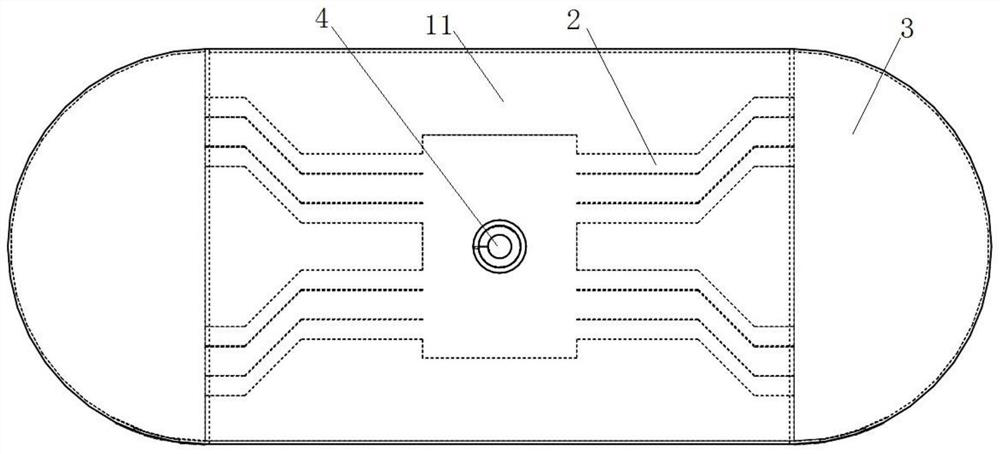

[0028] like Figure 1 to Figure 6 As shown, a compact jet cooling system includes a low melting point liquid metal flow channel 1, a jet area, a liquid storage tank 7, a peristaltic pump 6 and an electromagnetic pump 5; the low melting point liquid metal flow channel 1 is a flat rectangular flow channel structure, and the low melting point liquid metal flow channel 1 is filled with low melting point liquid metal, the inlet of the low melting point liquid metal flow channel 1 is connected to the outlet of the electromagnetic pump 5 through a pipeline, and the outlet is connected to the inlet of the electromagnetic pump 5 through a pipeline; The upper surface of the shell of the low melting point liquid metal flow channel 1 is provided with a special-shaped mesh channel 2, and the top of the special-shaped mesh channel 2 is covered by a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com