Preparation method and application of carbon-coated manganese selenide hollow cubic three-dimensional material

A cubic, manganese selenide technology, applied in electrochemical generators, active material electrodes, structural parts, etc., can solve problems such as poor Coulomb efficiency and cycle performance, and achieve easy popularization, alleviation of structural collapse, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]The method of preparing the three-dimensional material of the carbon coilchaized manganese hollow cube provided in this embodiment is specifically:

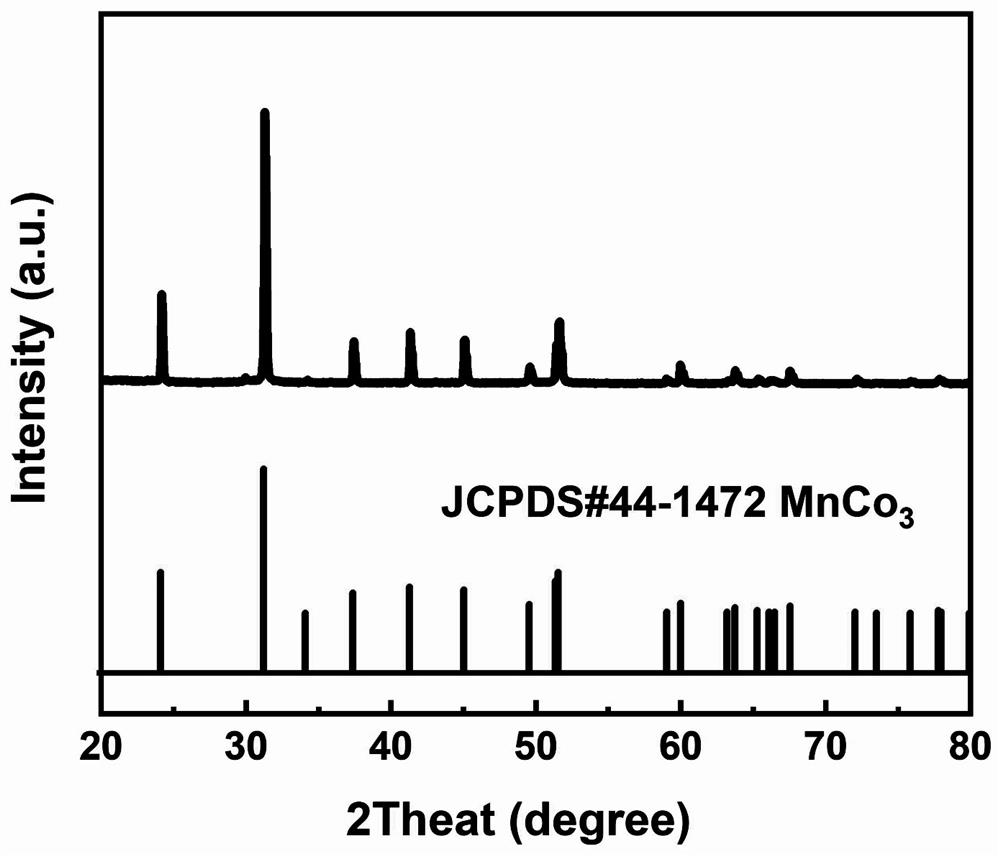

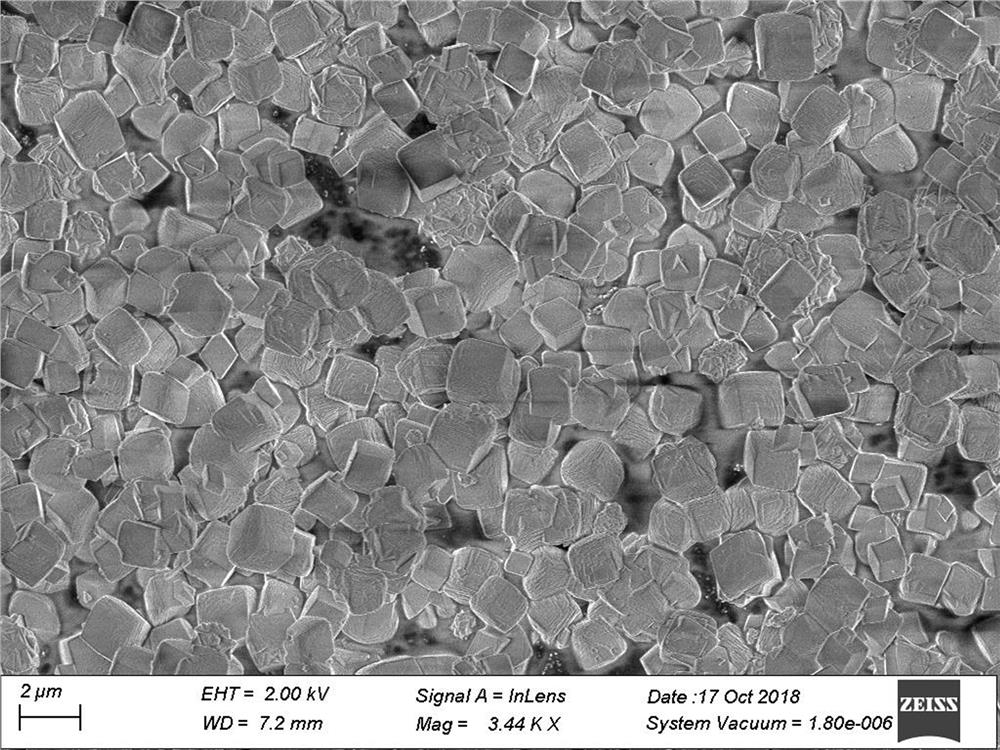

[0039]Preparation of manganese carbonate cubes: prepared a carbonate cube with hot solution, take 10 mmol MnSO4· H2O and 100mmol (NH4)2SO4Dispersed in 70 mL of anhydrous ethanol, then 700 ml of deionized water was added to stir well and mixed with a solution A; take 100 mmol NH4HCO3The mixture was mixed in a solution of 700 mL of deionized water and stirred with a solution B; the B solution was added to a solution, heated to 40 ° C and stirred 8 h; after the reaction was completed, centrifuged and mixed with deionized water / ethanol Wash, dry at 65 ° C, to obtain a manganese carbonate cube, topographyimage 3 As shown, the XRD figure of the carbonate cube is asfigure 1 Indicated. In this step, one of 40-60 ° C is strongly stirred at a temperature (e.g., 45 ° C, 48 ° C, 50 ° C, 55 ° C, 60 ° C), and the stirring time can also be contr...

Embodiment 2

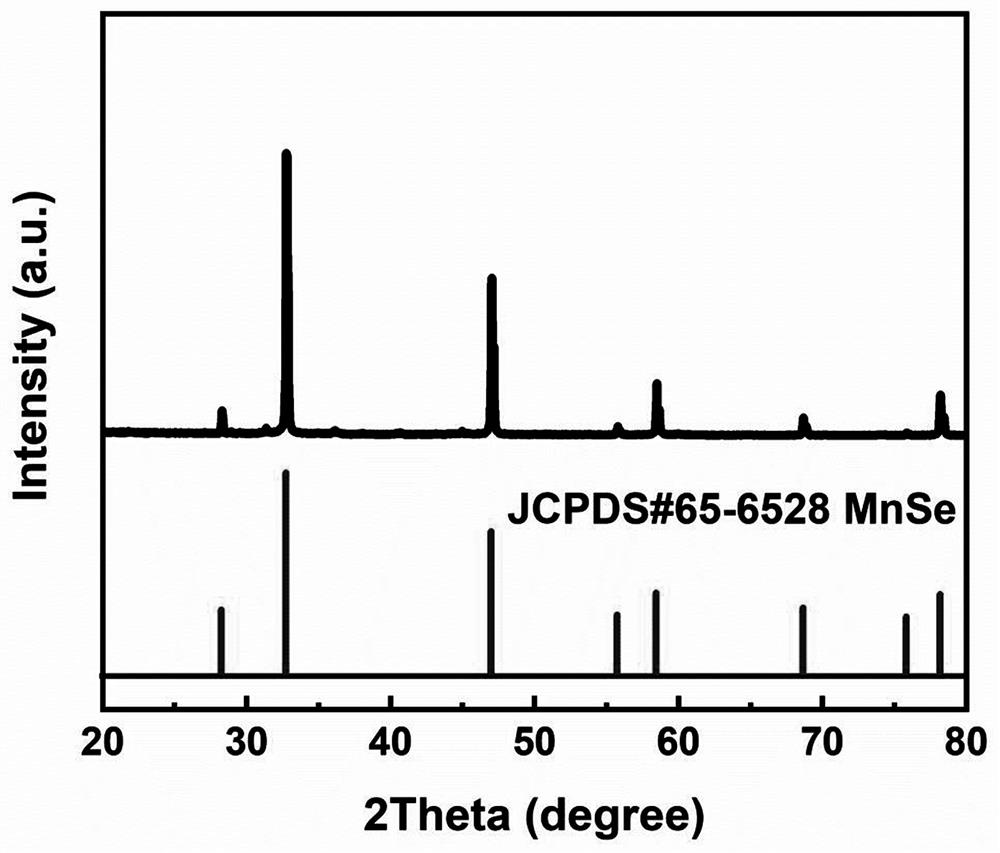

[0043]The method of preparing the three-dimensional material provided by the carbon coated manganese in this embodiment is the same as that of Example 1, and in the first embodiment, the prepared carbonate cubic liquid phase is obtained in the step of selenide manganese hollow cube: mixed The solution was transferred to 100 mL of stainless steel reaction kettle heated 200 ° C and held 20 h, and the topographical map of the selenide manganese cube is obtained.Figure 5 Indicated.

Embodiment 3

[0045]The method of preparing the three-dimensional material provided by the carbon coated manganese in this embodiment is the same as that of Example 1, and in the first embodiment, the prepared carbonate cubic liquid phase is obtained in the step of selenide manganese hollow cube: mixed The solution was transferred to 100 mL of stainless steel reaction kettle heated 200 ° C and held 16 h, and the topographical map of the selenide manganese cubic cube is obtained.Figure 6 Indicated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com