Online desulfurization system and method for storage batteries based on frequency conversion signals

A technology for storage batteries and storage battery packs, applied in secondary batteries, secondary battery testing, secondary battery repair/maintenance, etc., can solve the problems of selecting pulse signals for the degree of vulcanization of batteries, reducing the service life of batteries, reducing battery capacity, etc., to achieve Ensure the effect of sulfur removal, reduce waste of resources, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the technical content of the present invention, a specific embodiment is provided below, and the present invention is further described in conjunction with the accompanying drawings.

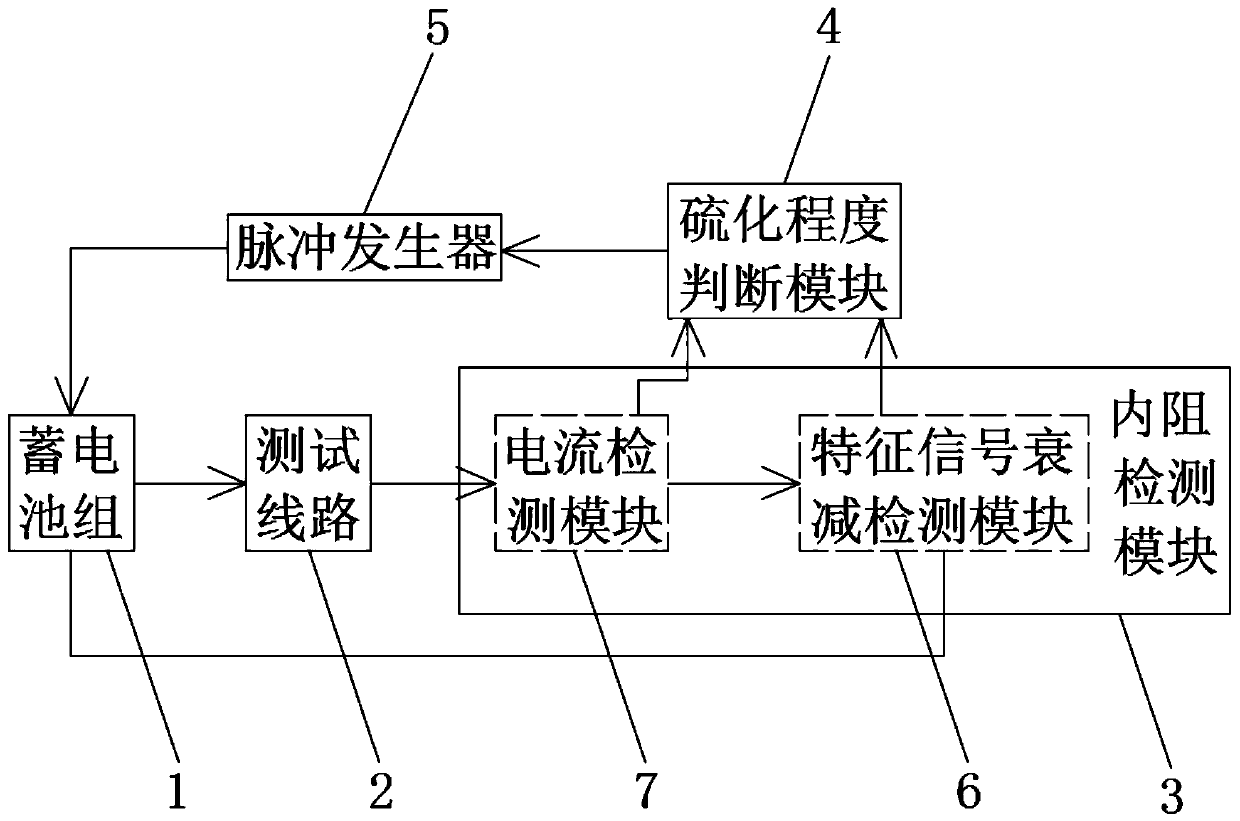

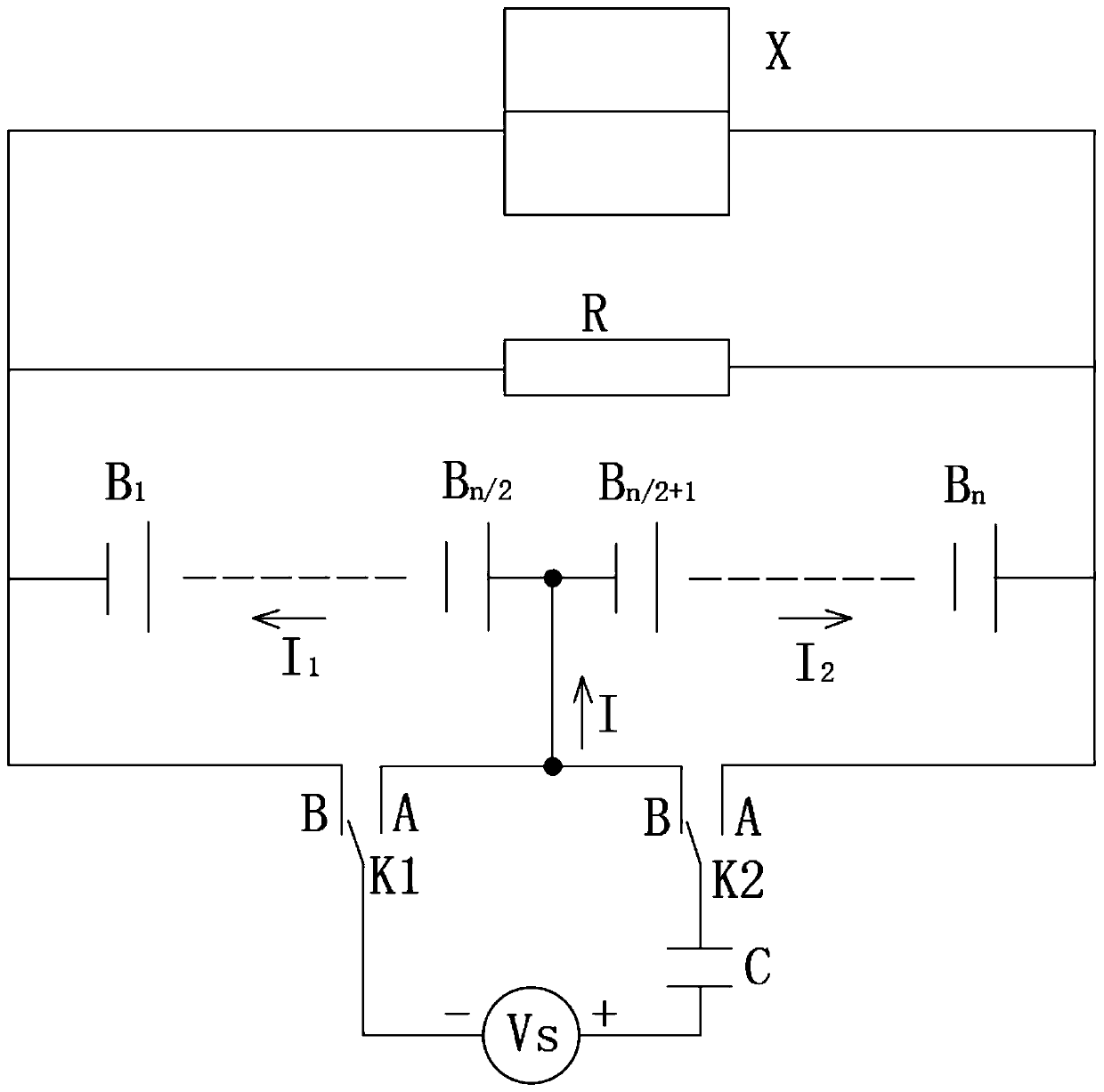

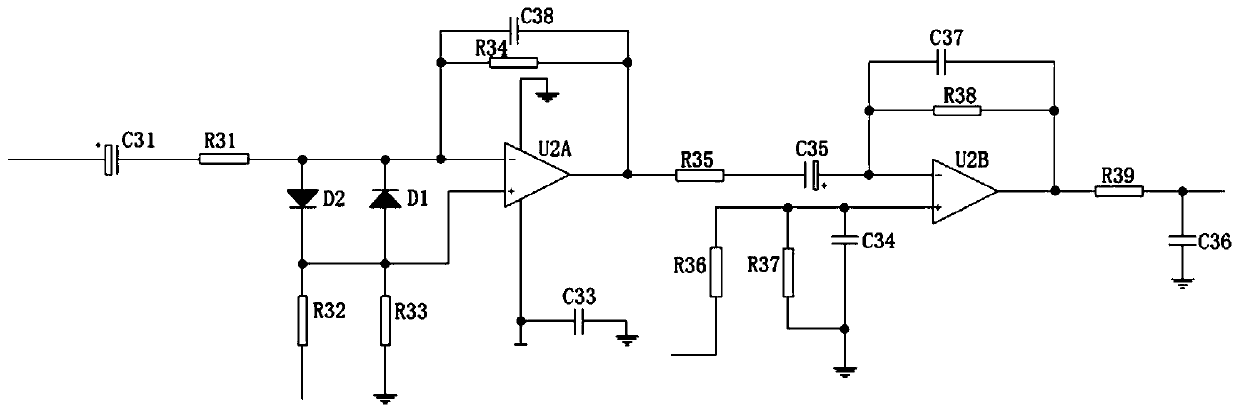

[0036] see Figure 1 to Figure 3 , an on-line desulfurization system for batteries based on frequency conversion signals provided by the present invention includes a DC system, a test line 2, an internal resistance detection module 3, a vulcanization degree judgment module 4, and a pulse signal generator 5. The DC system includes a parallel connection The storage battery pack 1, the load resistance and the charger, the storage battery pack 1 is electrically connected with the test line 2, the internal resistance detection module 3 and the pulse signal generator 5 respectively, and the internal resistance detection module 3 is respectively connected with the test line 2 and the vulcanization Degree judging module 4 signal connections, described vulcanization d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com