Manufacturing process of large thin-wall high-cylinder ring axial continuous path stirring friction additive

An additive manufacturing and friction stir technology, applied in manufacturing tools, additive processing, metal processing equipment, etc., can solve problems such as difficulty in controlling the uniformity of the structure, material properties at the keyhole without consideration, and large equipment and site requirements. , to ensure machining accuracy and surface quality, reduce material waste and performance defects, and enhance applicability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

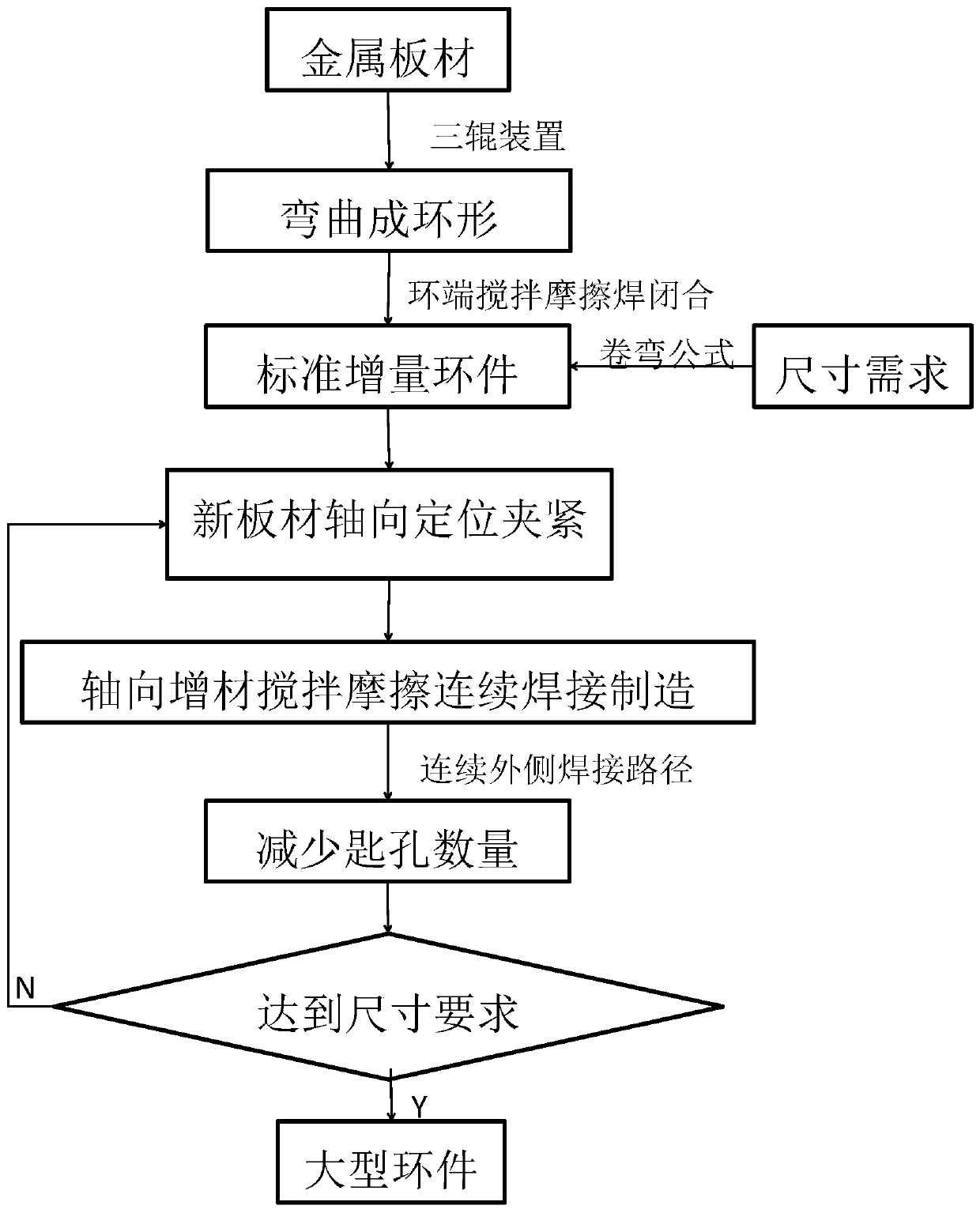

[0044] Embodiment one, such as figure 1 As shown, an axial continuous path friction stir additive manufacturing process for large thin-walled high-tube rings includes the following steps:

[0045]Step 1: Determine the size and quantity of plates used for standard incremental rings;

[0046] 1.1 Dimensions of strips used for standard rings in roll bending;

[0047] The dimensions of the formed and manufactured large thin-walled cylindrical parts are outer diameter D, wall thickness T, and height H, and the large thin-walled cylindrical parts are made of N-layer standard incremental ring parts with continuous path friction stir welding and axial addition;

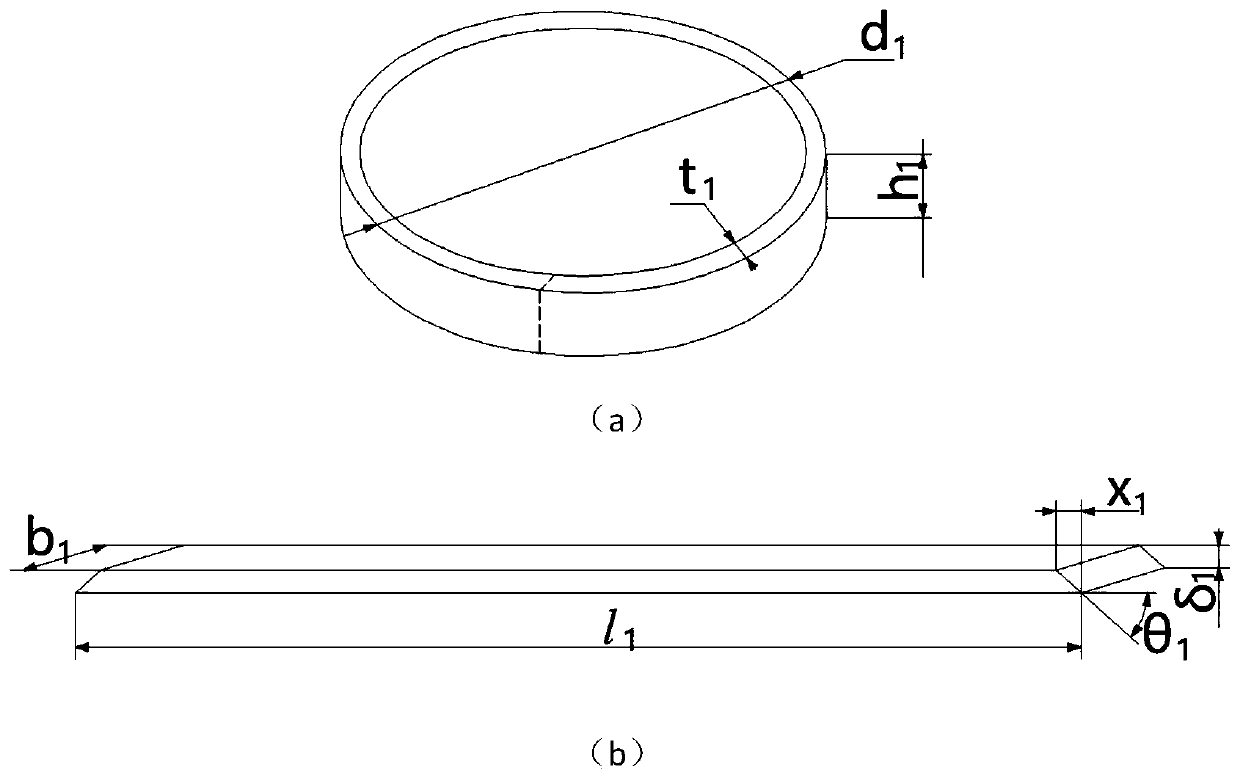

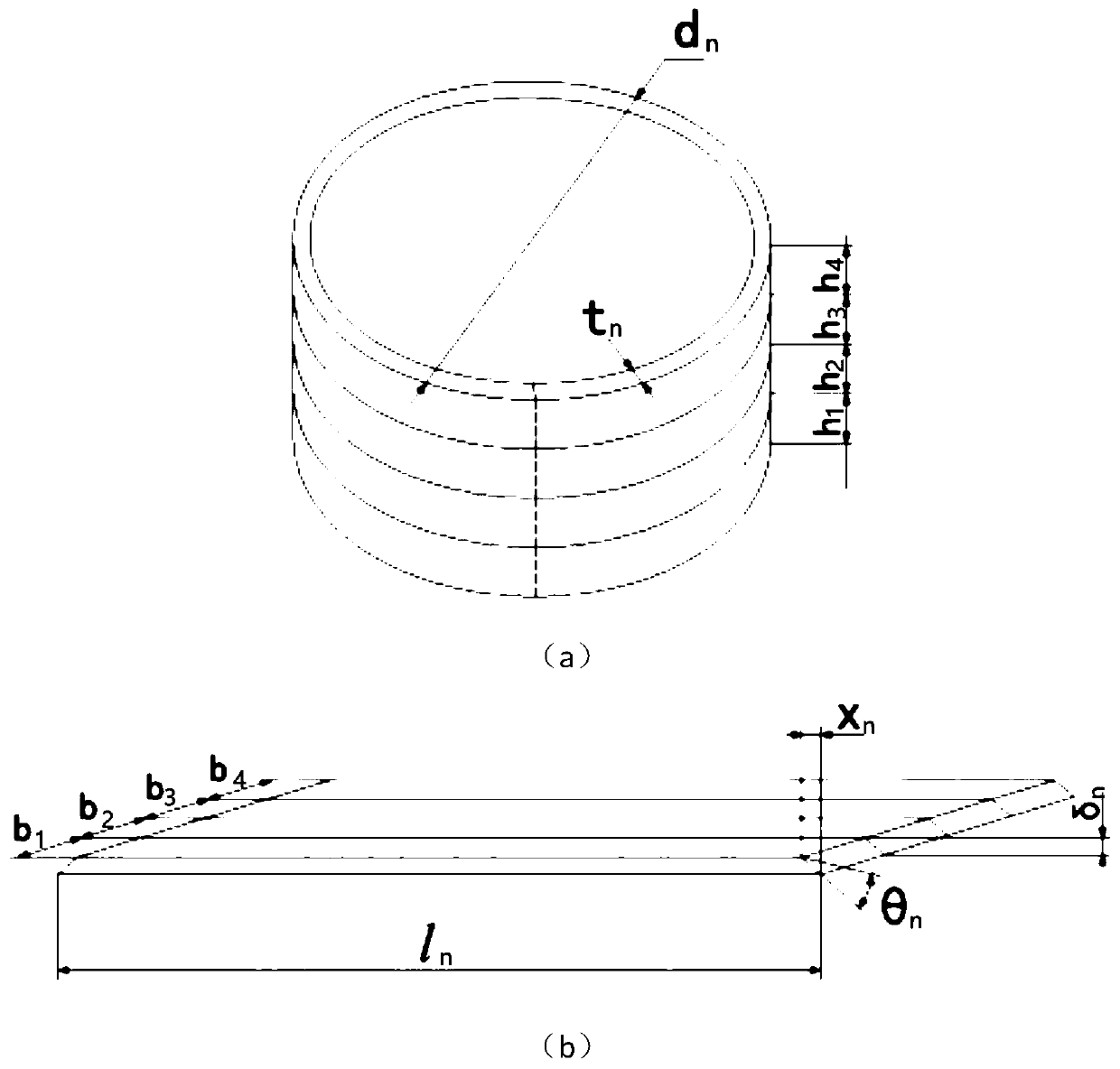

[0048] The first layer of standard incremental rings: the first layer of standard incremental rings such as figure 2 As shown in (a), outer diameter d 1 ≥D, wall thickness t 1 ≥T, the outer diameter of the standard incremental ring for axial addition is the same as that of the large thin-walled cylindrical part. Consider...

Embodiment 2

[0071] Embodiment two, such as figure 1 As shown, an axial continuous path friction stir additive manufacturing process for large thin-walled high-tube rings includes the following steps:

[0072] Step 1: Determine the size and quantity of plates used for standard incremental rings;

[0073] 1.1 Dimensions of strips used for standard rings in roll bending;

[0074] The dimensions of the formed and manufactured large thin-walled cylindrical parts are outer diameter D, wall thickness T, and height H, and the large thin-walled cylindrical parts are made of N-layer standard incremental ring parts with continuous path friction stir welding and axial addition;

[0075] The first layer of standard incremental rings: the first layer of standard incremental rings such as figure 2 As shown in (a), outer diameter d 1 ≥D, wall thickness t 1 ≥T, the outer diameter of the standard incremental ring for axial addition is the same as that of the large thin-walled cylindrical part. Conside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com