Pre-filling needle nest separator

A pre-filling and nest box technology, applied in bottle filling, liquid bottling, packaging, etc., can solve the problems of low workshop area utilization rate and large floor space, and achieve a compact and complete overall, convenient recycling operation, and space saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

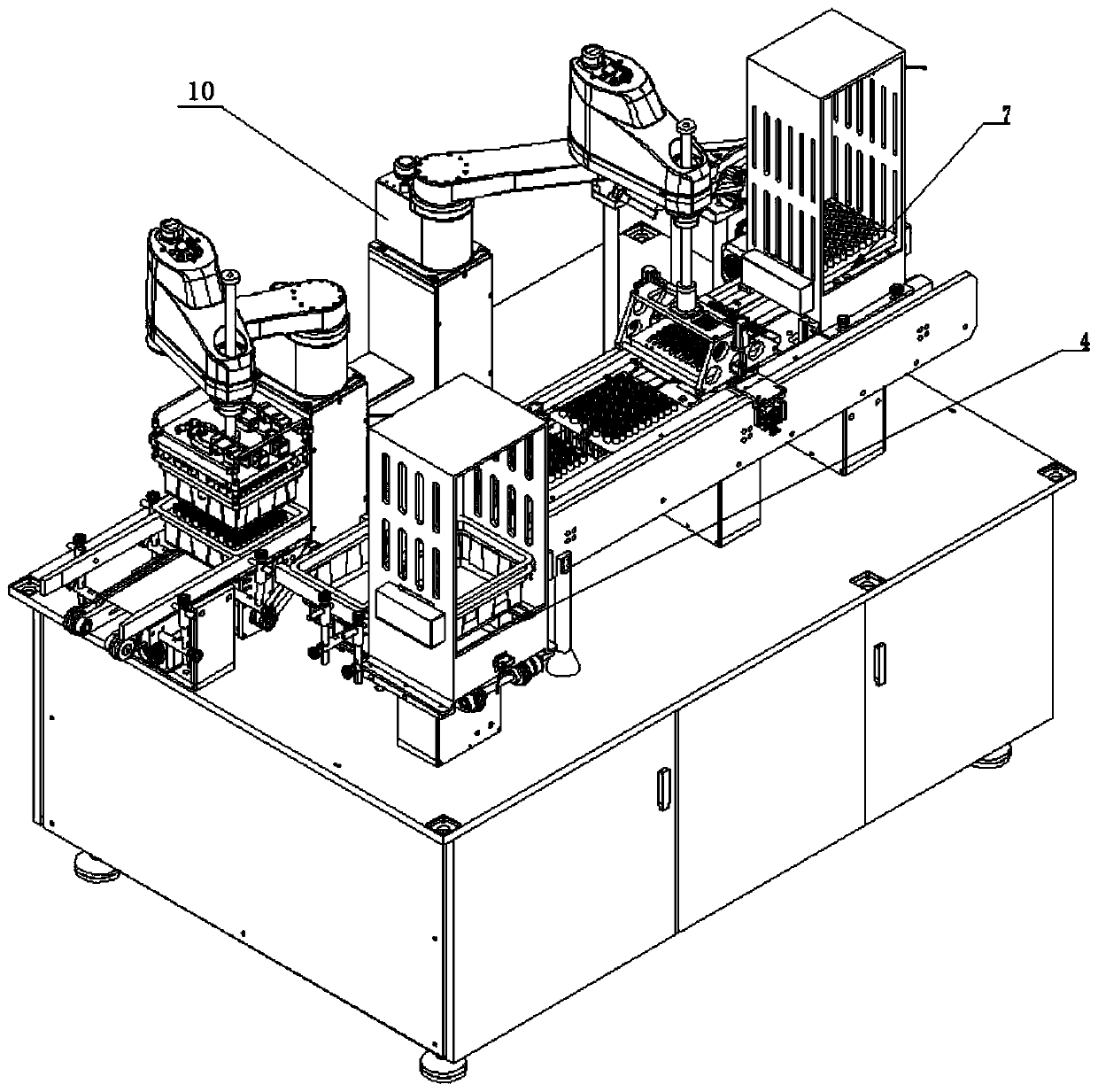

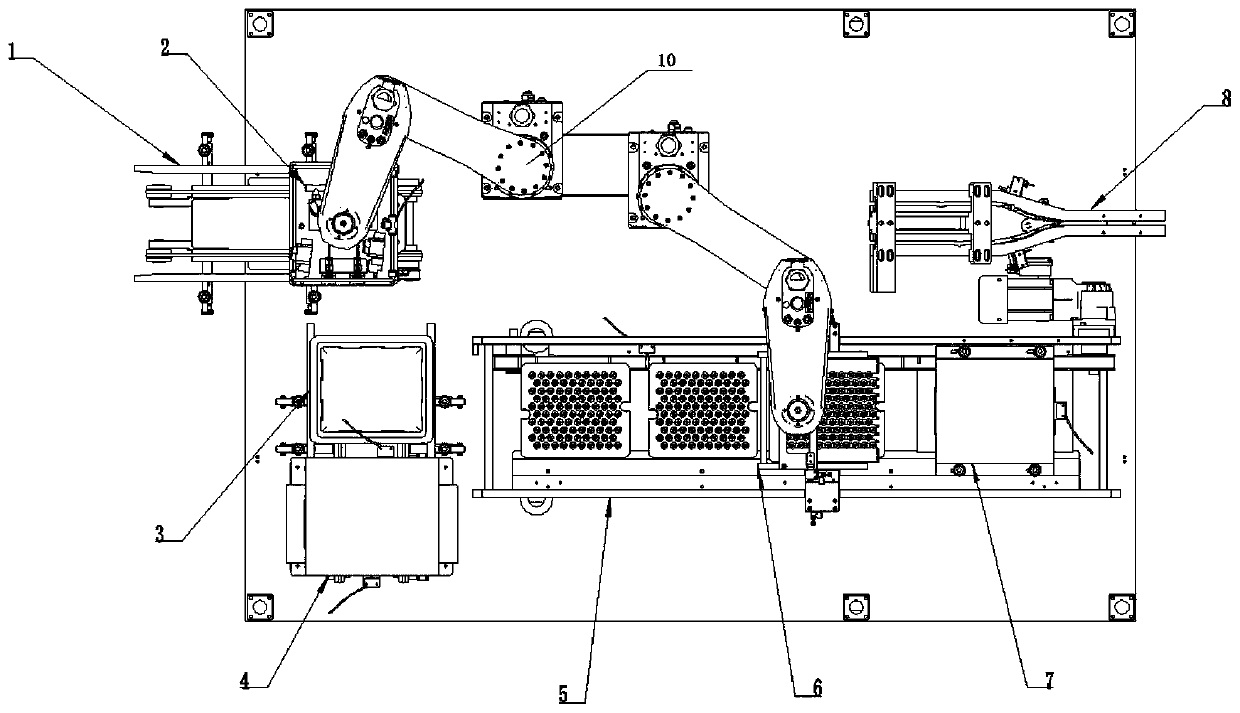

[0031] Such as Figure 1-9 As shown, it is a kind of prefilled needle denesting machine provided by the present invention, which includes a nest plate separation mechanism 2 for separating the nest plate from the nest box, and is used to collect the nests of the nest box on the nest box feeding mesh belt 3 Box reclaim mechanism 4, be used for the nest board feeding mechanism 5 that nest board is conveyed to nest board recovery mechanism 7, be used to transfer the prefilling needle transfer mechanism 6 of the prefilled needle in the nest board on the nest board feeding mechanism 5 and robotic arm 10. The feeding mesh belt 1 can be rotated or rotated on its own, satisfying various feeding directions of packaging materials equipped with prefilled needles.

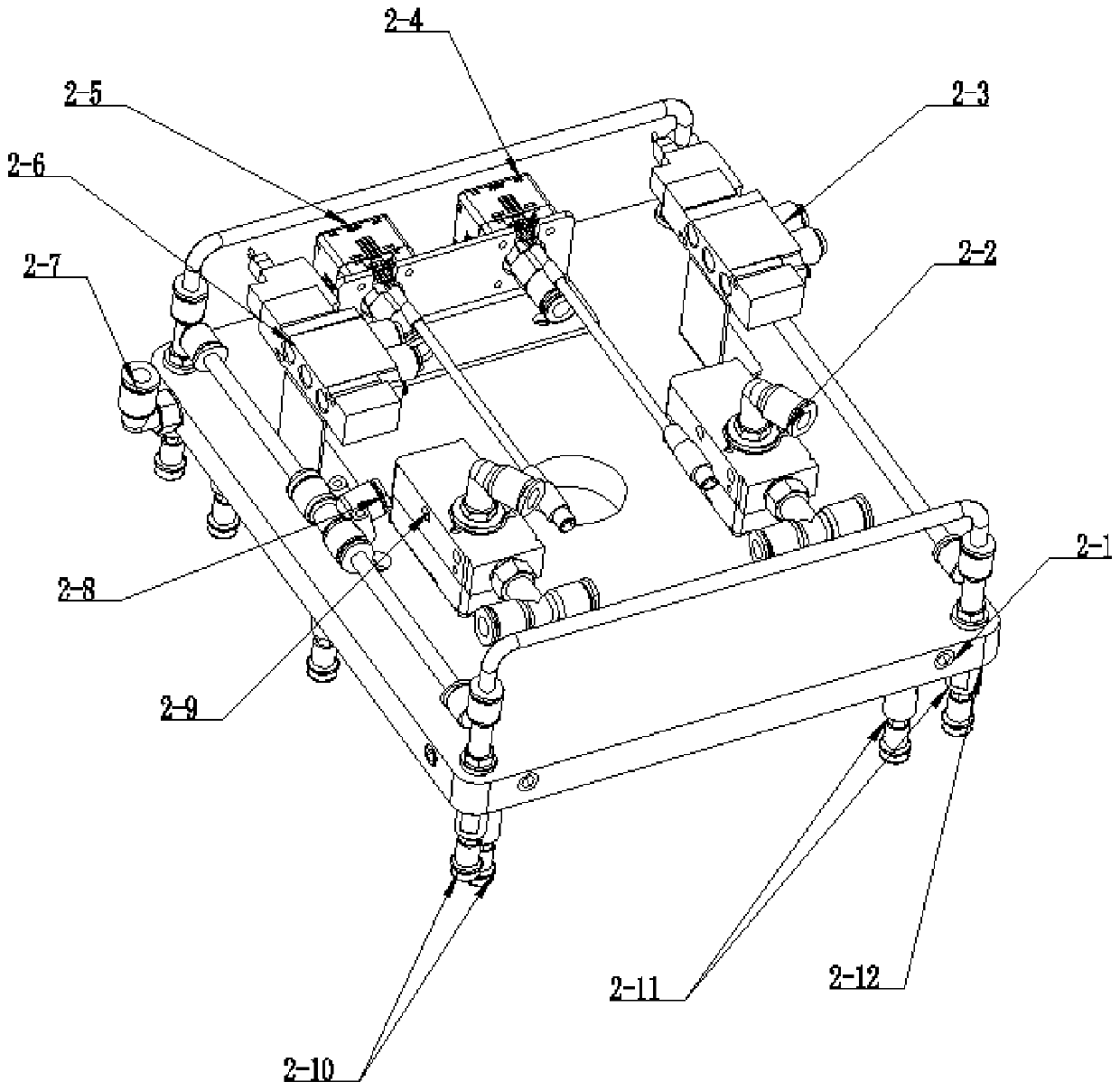

[0032] Such as image 3 As shown, the nest plate separation mechanism 2 includes two sets of vacuum components arranged on the vacuum plate 2-12 for absorbing the nest plate and the nest box respectively, and the two sets of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com