Manufacturing method of micro three-dimensional stacked MEMS (Micro Electro Mechanical System) resonance device

A manufacturing method and resonance technology, applied in electrical components, impedance networks, etc., can solve problems such as the fact that the heating phenomenon of the ASIC cannot be completely eliminated, the structural strength of the casing cannot be increased without limit, and the deformation of the chip structure cannot be avoided, so as to achieve convenient electrical connection. , the effect of ensuring performance and reducing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

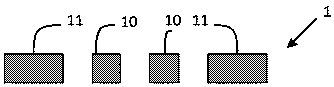

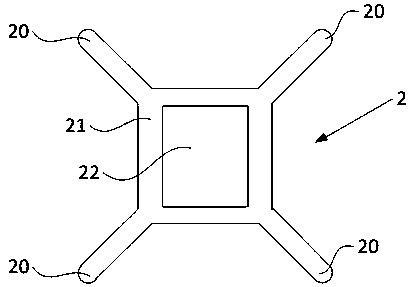

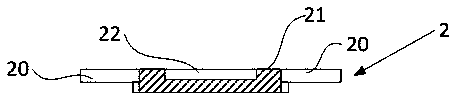

[0036] The invention discloses a method for manufacturing a miniature three-dimensional stacked MEMS resonant device, such as Figure 7 and Figure 8 As shown, the micro three-dimensional stacked MEMS resonator device includes an open housing 42, a cap 62 that seals the housing 42 and a conductive chip holder 2, and the chip holder 2 and the resonator chip 1 thermally expand The coefficients are the same (the chip support 2 and the resonant chip 1 can be made of the same material), the resonant chip 1 includes a resonant beam 10 and a fixed part 11, and the resonant chip 1 is installed on the chip support 2 through the fixed part 11 and makes the resonant The beam 10 is suspended, the chip support 2 is installed on the inner wall of the shell 42 and electrically connected with the shell 42, the inner bottom surface of the shell 42 below the chip support 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com