Polymer super-strong mass transfer deepening instant dissolving device

A polymer, super technology, used in mixers, dissolvers, mixers and other directions with rotary stirring devices, it can solve the problems of large dispensing volume, high viscosity retention rate, small volume and floor space, etc. Large volume, enhanced recovery, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

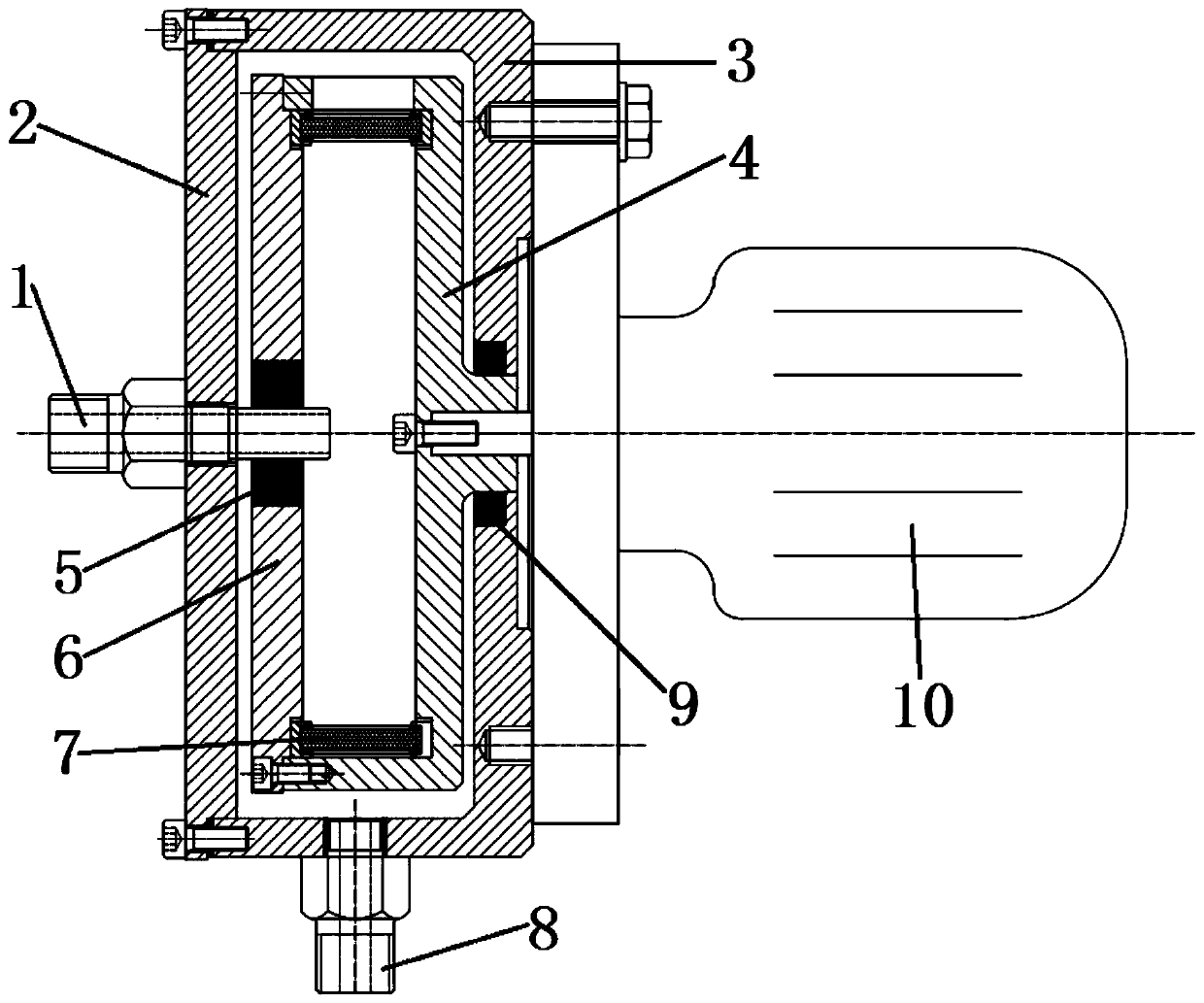

[0030] Such as figure 1 As shown, a kind of polymer supermass transfer deepening instant dissolving device of the present invention comprises housing 3, the end cover 2 that is connected on described housing 3 by bolts, motor 10 and is arranged in described housing 3 The mass transfer tray 4, the mass transfer ring 7, and the tray cover 6 on the mass transfer tray 4 are connected by bolts; the motor 10 is axially installed on the housing 3;

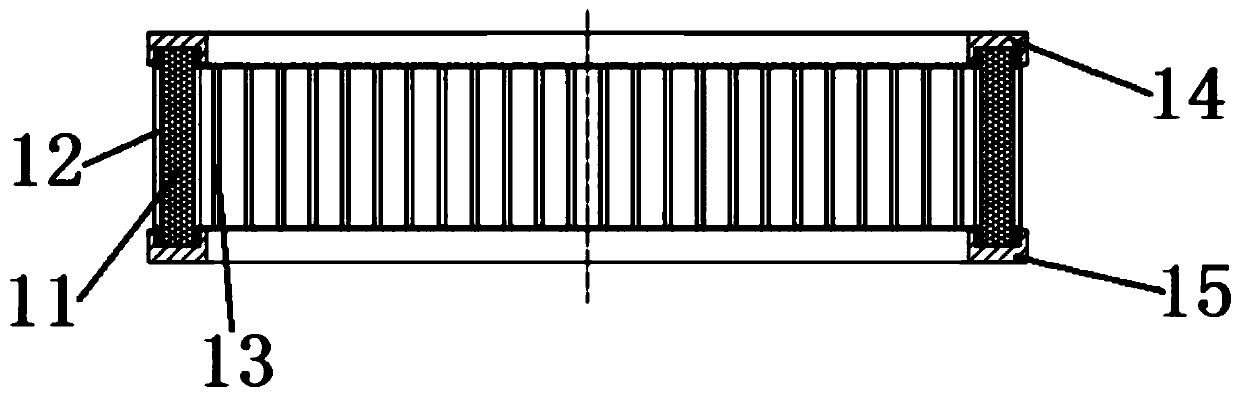

[0031] Such as Figure 4 and 5 As shown, the mass transfer tray 4 has a connecting portion connected to the motor 10, and an annular slot A16 matching the mass transfer ring 7;

[0032] Such as Figure 6 and 7 As shown, the tray cover plate 6 is axially provided with a through hole for penetrating the liquid pipe 1, and is used for inserting the ring-shaped slot B19 of the mass transfer ring 7;

[0033] The mass transfer tray 4 is connected to the rotating shaft of the motor 10; the annular engaging groove A16 and the annular engagin...

Embodiment 2

[0039] Such as Figure 8 As shown, a polymer super mass transfer deepening instant dissolving device of the present invention is also equipped with a cleaner 17 on the basis of Embodiment 1, wherein the cleaner 17 is installed into the liquid inlet pipe 1 and extends into the mass transfer tray 4 on one end.

[0040] In the second embodiment, if Figure 9 and 10 As shown, the cleaner 17 is a cross-shaped impeller, the impeller is four L-shaped blades 18, the L-shaped blades 18 are perpendicular to the mass transfer ring 7, this design can better clean the mass transfer ring 7 The polymer swelling particles on the surface, the distance between the cleaner 17 and the mass transfer ring 7 is determined according to the particle diameter of the polymer swelling particles.

[0041]When this embodiment is in use: the liquid inlet pipe 1 is connected with the outlet of the on-site liquid transfer screw pump, and the liquid outlet 8 is connected with the inlet of the aging tank. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com