Semi-automatic precast stair turning-over machine

A turning machine, semi-automatic technology, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of increasing the cost of turning stairs, easy to bump corners, low work efficiency, etc., to improve production and turning efficiency, Ease of security and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

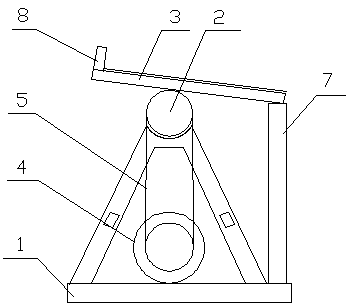

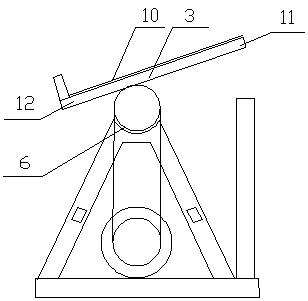

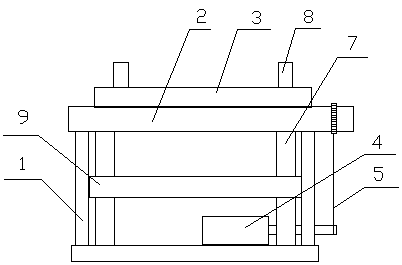

[0019] As shown in the figure, in a semi-automatic prefabricated stair turning machine according to the present invention, the turning frame 3 forms a seesaw structure above the triangular base bracket 1, and the two use the rotating shaft 2 as the center point of turning, and the driving motor 4 passes through The chain 5 drives the rotating shaft 2 to rotate. During work, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap