Ceramic copper clad laminate and its preparation process and application

A technology of ceramic copper clad laminate and preparation process, which is applied in the direction of chemical instruments and methods, coatings, metal layered products, etc., can solve the problems affecting the use of appearance products, large copper grains on the upper surface of ceramic copper clad laminates, etc., and achieve crystal The effect of small particles and high automatic recognition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

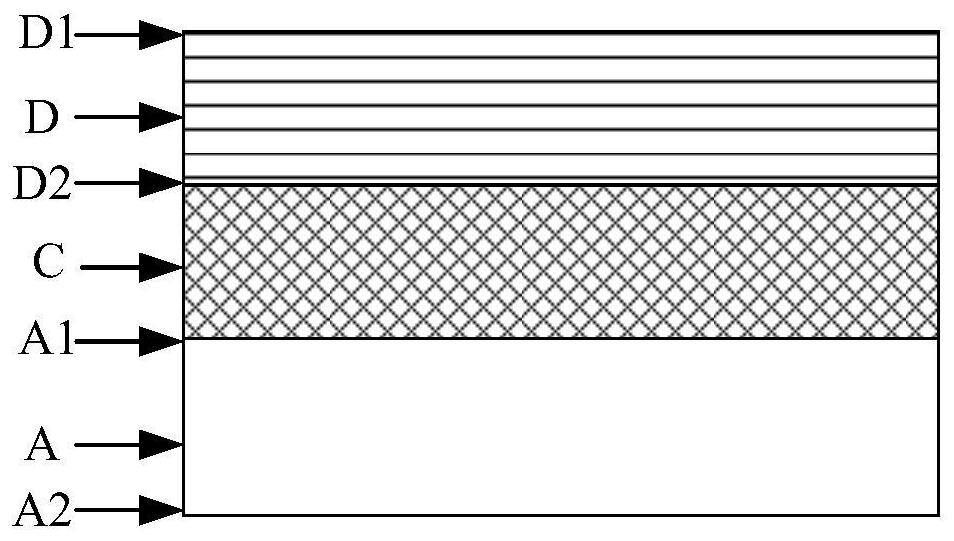

[0036] The present disclosure provides a preparation process of a ceramic copper clad laminate, the process comprising:

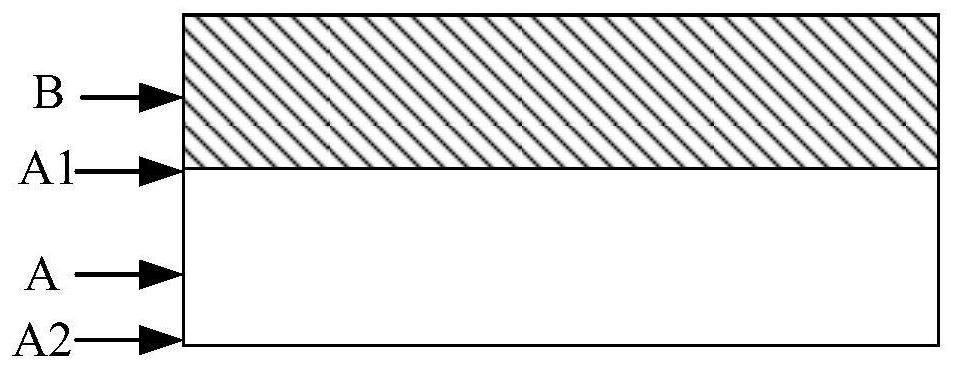

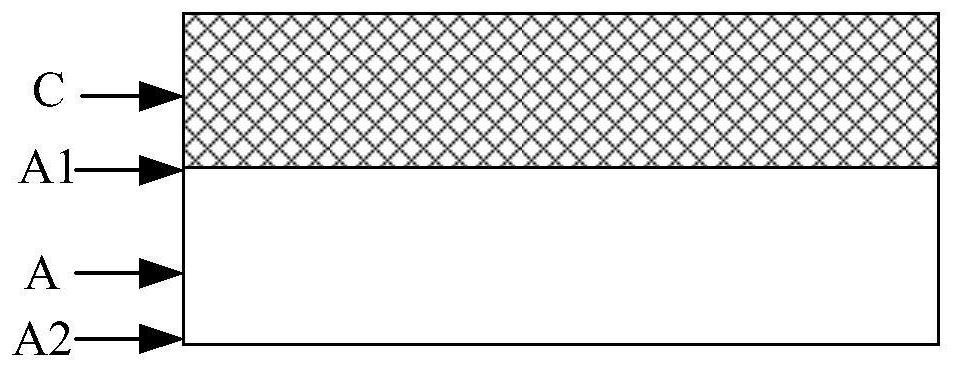

[0037] S1, forming a copper layer on the surface of the ceramic backing plate, and then performing a first thermal oxidation treatment on the surface of the copper layer to obtain an oxidized backing plate;

[0038] S2. Place the copper sheet on the copper layer of the oxidized backing plate after the first thermal oxidation treatment, perform the second thermal oxidation treatment on the oxidized backing plate and the copper sheet, and then separate the two to obtain the copper oxide sheet; The surface of the copper oxide sheet separated from the oxide backing plate is the first surface, and the surface of the copper oxide sheet opposite to the first surface is the second surface;

[0039] S3, bonding the second surface to the ceramic substrate, and then performing cladding treatment to obtain a ceramic copper clad laminate.

[0040] In the disclosed proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com