Closed circulating evaporation and condensation system for treating high-salt and high-COD wastewater

A closed cycle and wastewater treatment technology, applied in the direction of heating water/sewage treatment, etc., can solve the problems of investment, high operating cost, adverse environmental impact, difficult operation management, etc., and achieve short heat transfer distance, efficient evaporation, and improved evaporation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

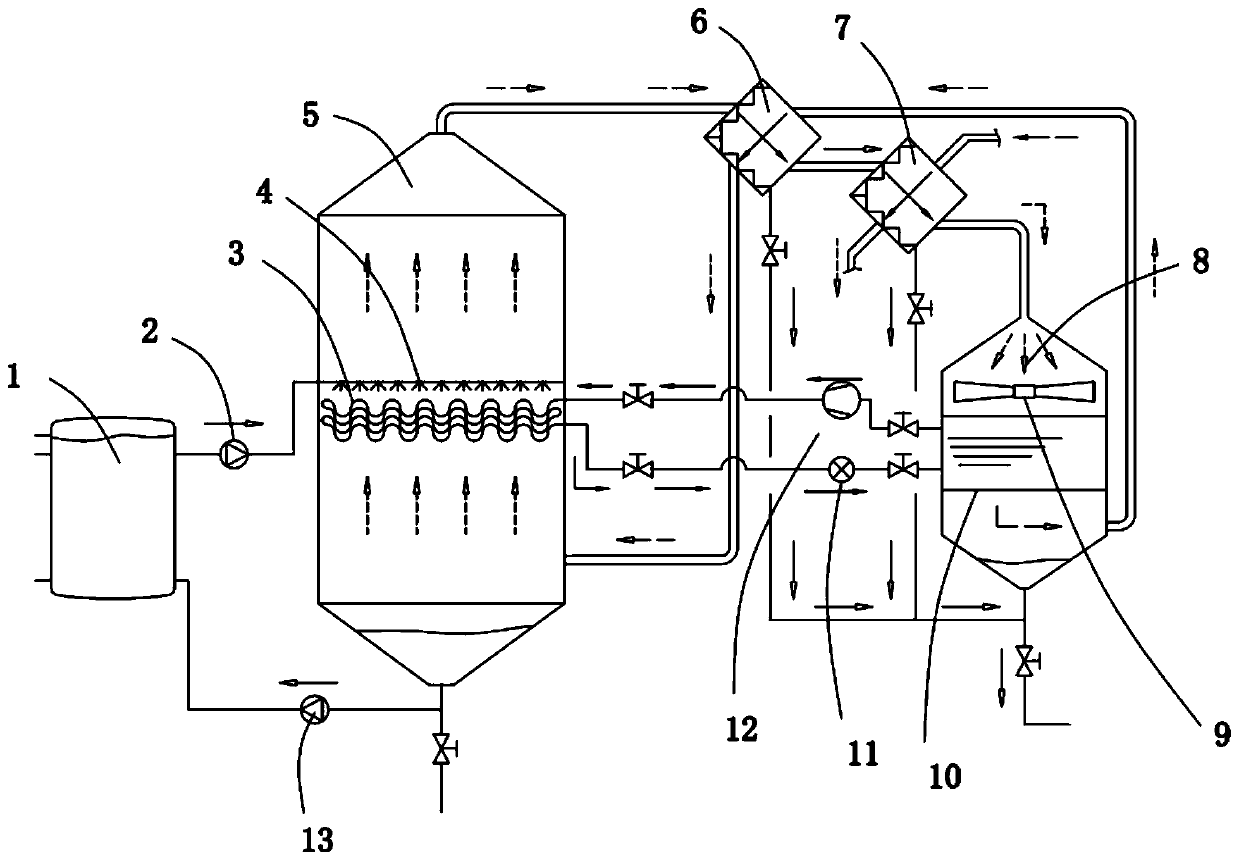

[0023] Please refer to figure 1 , in the first embodiment of the present invention, the closed cycle evaporative condensation system used for the treatment of high-salt and high-COD wastewater includes reverse Carnot cycle heat pumps connected in turn to form a circulation loop for heating evaporative wastewater and condensing purified water system, the heat pump subsystem includes: compressor unit 12 (main components such as oil separator, liquid storage tank, dry filter, sight glass, gas-liquid separator, etc. figure 1 Not marked in), (evaporative cooling titanium pipeline) condenser 3, throttling element (electronic expansion valve) 11, evaporator 10, and supporting refrigerant pipelines, valves, etc.; used for waste water transportation, spraying The waterway subsystem for showering and collecting discharge, the waterway subsystem includes: waste w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com