Automatic processing device of thermal power plant mortar

An automatic processing and thermal power plant technology, applied in the field of thermal power plants, can solve the problems of many operating points, large water consumption, poor operation, etc., to ensure the filtering effect and reduce the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

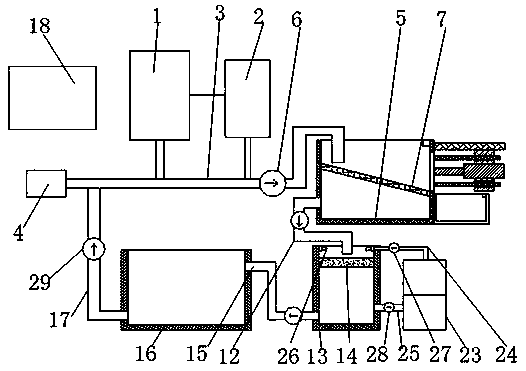

[0023] Example 1, please refer to Figure 1-2 , according to an embodiment of the present invention, an automatic processing device for ash in a thermal power plant includes a boiler 1, a dust collector 2 is connected to one side of the boiler 1, and both the boiler 1 and the dust collector 2 are connected to the ash flushing water pipe 3 , one end of the gray flushing water pipe 3 is connected to the water supply device 4, the other end of the gray flushing water pipe 3 is located at the top of the filter box one 5, the gray flushing water pipe 3 is connected with a mortar pump 6, and the filter box one The inside of 5 is fixedly connected with a filter screen 7. It should be noted that the filter screen 7 is obliquely connected with the filter box-5, and the port of the gray water pipe 3 is located on the higher side of the filter screen 7. The filter box-5 One side of one side is provided with baffle plate 8, and baffle plate 8 is positioned at the lower side of filter scre...

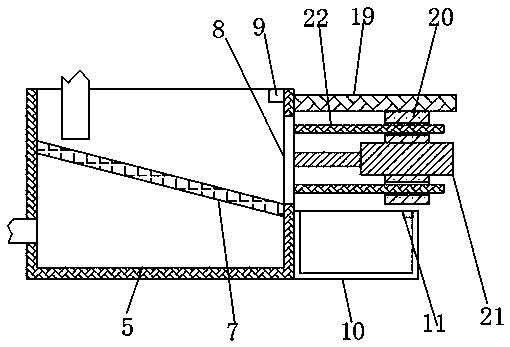

Embodiment 2

[0026] Example 2, please refer to figure 2 , the moving mechanism includes a support plate 19, a support frame 20 and a hydraulic telescopic rod 21, the top of one side of the filter box 5 close to the baffle plate 8 is fixedly connected with a support plate 19, and the bottom of the support plate 19 is fixed A support frame 20 is connected, and a hydraulic telescopic rod 21 is fixedly connected to the support frame 20 , and the movable end of the hydraulic telescopic rod 21 is fixedly connected to the baffle plate 8 .

Embodiment 3

[0027] Embodiment three, please refer to figure 2 , the side of the baffle plate 8 close to the hydraulic telescopic rod 21 is fixedly connected with a guide rod 22, the guide rod 22 is respectively located above and below the hydraulic telescopic rod 21, and the guide rod 22 is far away from the baffle. One end of the board 8 passes through the support frame 20 and extends to the other side of the support frame 20 , and the support frame 20 is provided with a corresponding hole for the guide rod 22 to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com