Interior wall putty powder

A technology of interior wall putty powder and heavy calcium powder is applied in the field of interior wall putty powder, which can solve the problems of complex components of interior wall putty powder, and achieve the effect of simple and feasible formula components and excellent batch scraping property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

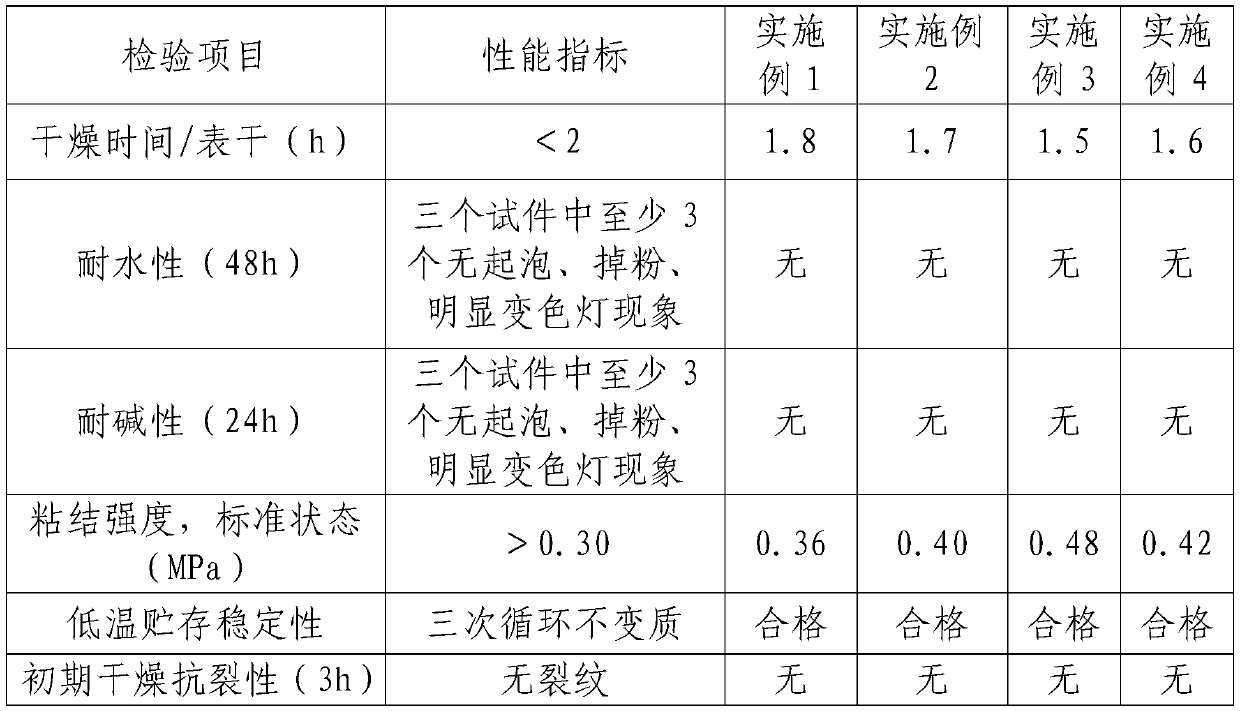

Examples

Embodiment 1

[0014] An interior wall putty powder, comprising the following raw materials in parts by weight: 980 parts of heavy calcium powder, 8 parts of corn pregelatinized starch, 2 parts of high-viscosity polyvinyl alcohol powder over 200 mesh, hydroxypropyl methyl cellulose ether 4.5 servings.

Embodiment 2

[0016] An interior wall putty powder, comprising the following raw materials in parts by weight: 1020 parts of heavy calcium powder, 10 parts of corn pregelatinized starch, 5 parts of high-viscosity polyvinyl alcohol powder over 200 mesh, hydroxypropyl methyl cellulose ether 5.5 servings.

Embodiment 3

[0018] An interior wall putty powder, comprising the following raw materials in parts by weight: 1,000 parts of heavy calcium powder, 9 parts of corn pregelatinized starch, 3 parts of high-viscosity polyvinyl alcohol powder over 200 mesh, hydroxypropyl methyl cellulose ether 5 servings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com