Cage type anti-scouring structure and construction method

A construction method and anti-scour technology, applied in shipping equipment, climate change adaptation and other directions, can solve the problems of not taking anti-scour measures, not considering the supporting role, secondary scouring, etc., achieving a significant anti-scour effect and improving the anti-scour ability. , the effect of economical and reasonable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the drawings and specific embodiments.

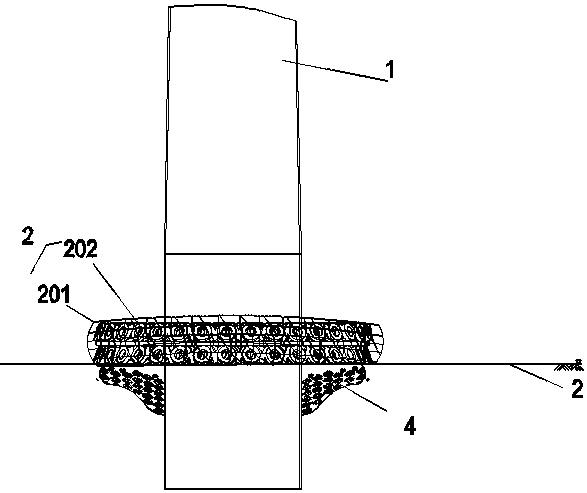

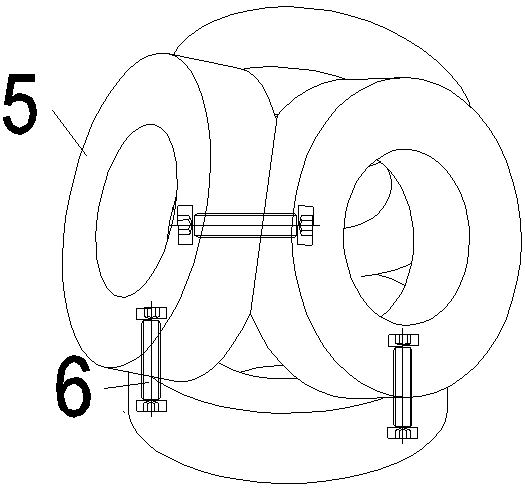

[0021] Such as Figure 1-2 As shown, a cage-type anti-scouring structure includes an anti-scouring member sheathed at the bottom of a pile foundation, the anti-scouring member is a geobag in a ring shape, or the anti-scouring member is surrounded by a plurality of geobags. It is a mesh with a certain width and is a water-permeable geosynthetic material made of synthetic fibers through needle punching or weaving, and has strong corrosion resistance. Each geobag can be formed by tying, tying, consolidating, etc. An annular structure, for example, adjacent geo-bags are tied by ropes, and a number of anti-scouring units are placed in the geo-bags. The anti-scouring units are surrounded by four tires in a cone shape. The tires are corrosion-resistant and rigid rubber materials. It can be a high molecular polymer such as polypropylene and polyvinyl chloride. The adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com