Water-level-reducing and draining structure with horizontal sand wells around foundation pit, and water-level-reducing and draining method

A sand well and horizontal technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of steep rainfall infiltration line, uneven ground settlement, large total precipitation, etc., and achieve the effect of drainage of foundation pit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

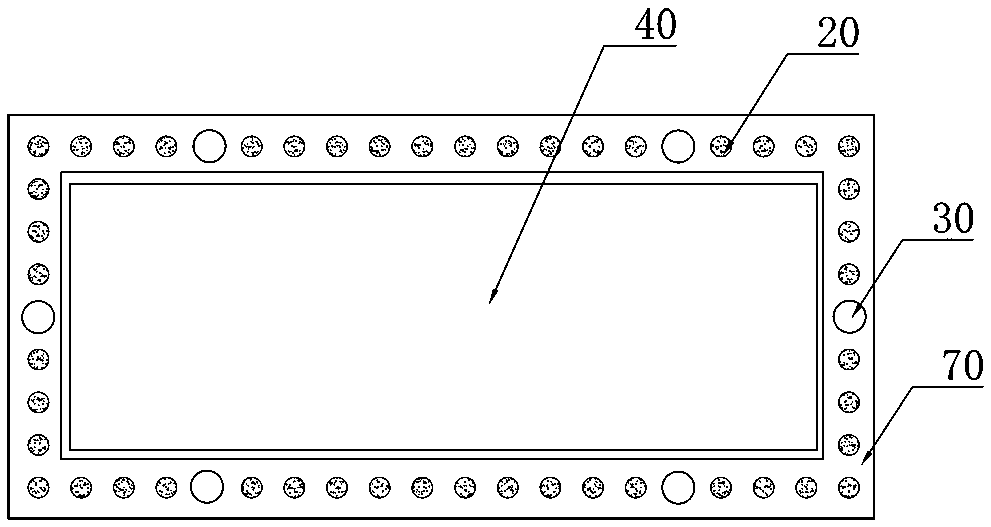

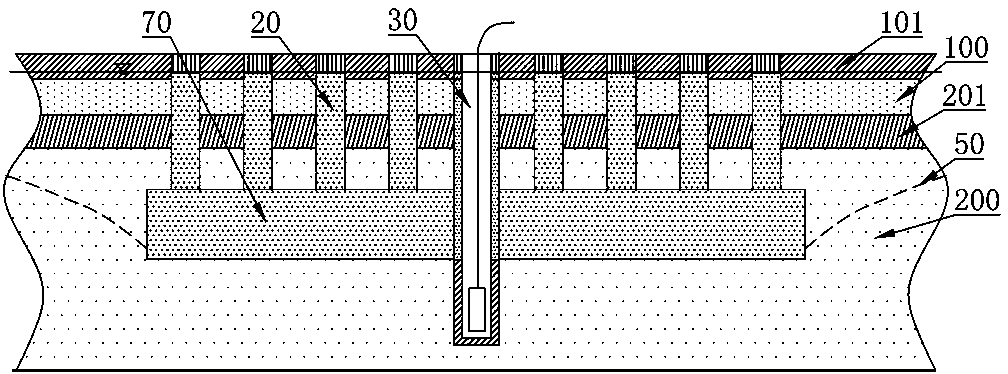

[0057] Such as figure 1 As shown, a horizontal sand well dewatering structure around the foundation pit includes several vertical sand wells 20 arranged at intervals around the foundation pit 40 and at least one horizontal sand well 70 arranged around the foundation pit 40. The horizontal sand wells 70 is located in the aquifer where the foundation pit 40 is located. The horizontal sand well 70 is connected to the vertical sand well 20. The horizontal sand well 70 is also connected to several vertical tube wells 30. Several vertical tube wells 30 are spaced around the foundation pit 40. Set, the vertical tube well 30 includes a water filtration section and a water storage section, and the water filtration section and the water storage section are arranged sequentially from top to bottom, and the dividing line between the water filtration section and the water storage section is located at the bottom of the lowest horizontal sand well 70 On the interface or below the bottom int...

Embodiment 2

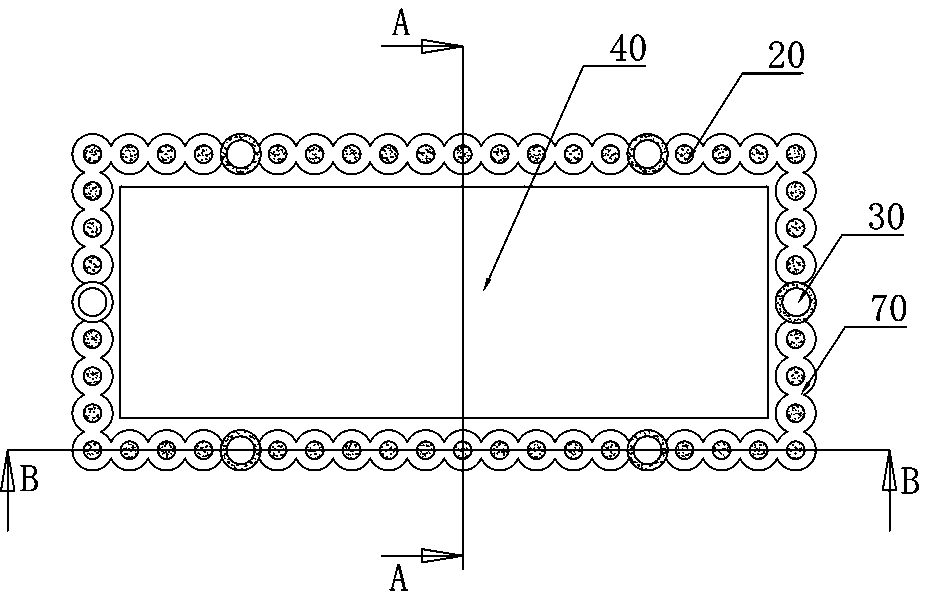

[0063] Based on the first embodiment, since the horizontal sand well 70 with a rectangular cross section is difficult and expensive in actual construction, in this embodiment, as Figure 3 to Figure 5 As shown, the horizontal sand well 70 includes several cylindrical sand columns 80 connected end to end in sequence and a retaining ring 60 located above the sand columns 80, there is a partial delivery between the adjacent sand columns 80, and the sand columns 80 and the vertical Set concentrically to the sand well 20. In the present embodiment, the sand column 80 is arranged concentrically with the vertical sand well 20, and when the vertical sand well 20 is drilled with a straight hole close to the horizontal sand well 70 position, the underwater soil expansion agitator is used to correct the horizontal sand well 70 position. The soil mass on the top is expanded, stirred and hardened to form retaining ring 60. The formed retaining ring 60 is umbrella-shaped, and then the soil ...

Embodiment 3

[0065] On the basis of the above examples, if Figure 3 ~ Figure 5 As shown, a method for dewatering and dewatering a horizontal sand well around a foundation pit comprises the following steps:

[0066] Step A. Determine the aquifer system according to the construction location of the foundation pit project, determine the thickness of each aquifer, the drawdown and the position of the lower aquifer, and judge the water content of each aquifer. In this embodiment, there are two in the scope of the foundation pit project Layer aquifers are the first aquifer 100 and the second aquifer 200. According to the basis that the deepest aquifer that has a harmful influence on foundation pit construction is the lower aquifer, it is judged that the second aquifer 200 is the lower aquifer;

[0067] Step B. Calculate the position and size of the horizontal sand well 70 located in the lower aquifer under the condition that the precipitation infiltration line in the foundation pit is 0.5m belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com