Orientation adjusting device for mine drilling and adjusting method thereof

An adjustment device and mine technology, applied in drilling equipment and methods, directional drilling, support devices, etc., can solve the problems of increasing the labor intensity of users, inability to adjust flexibly, and achieve the effect of reducing the intensity of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

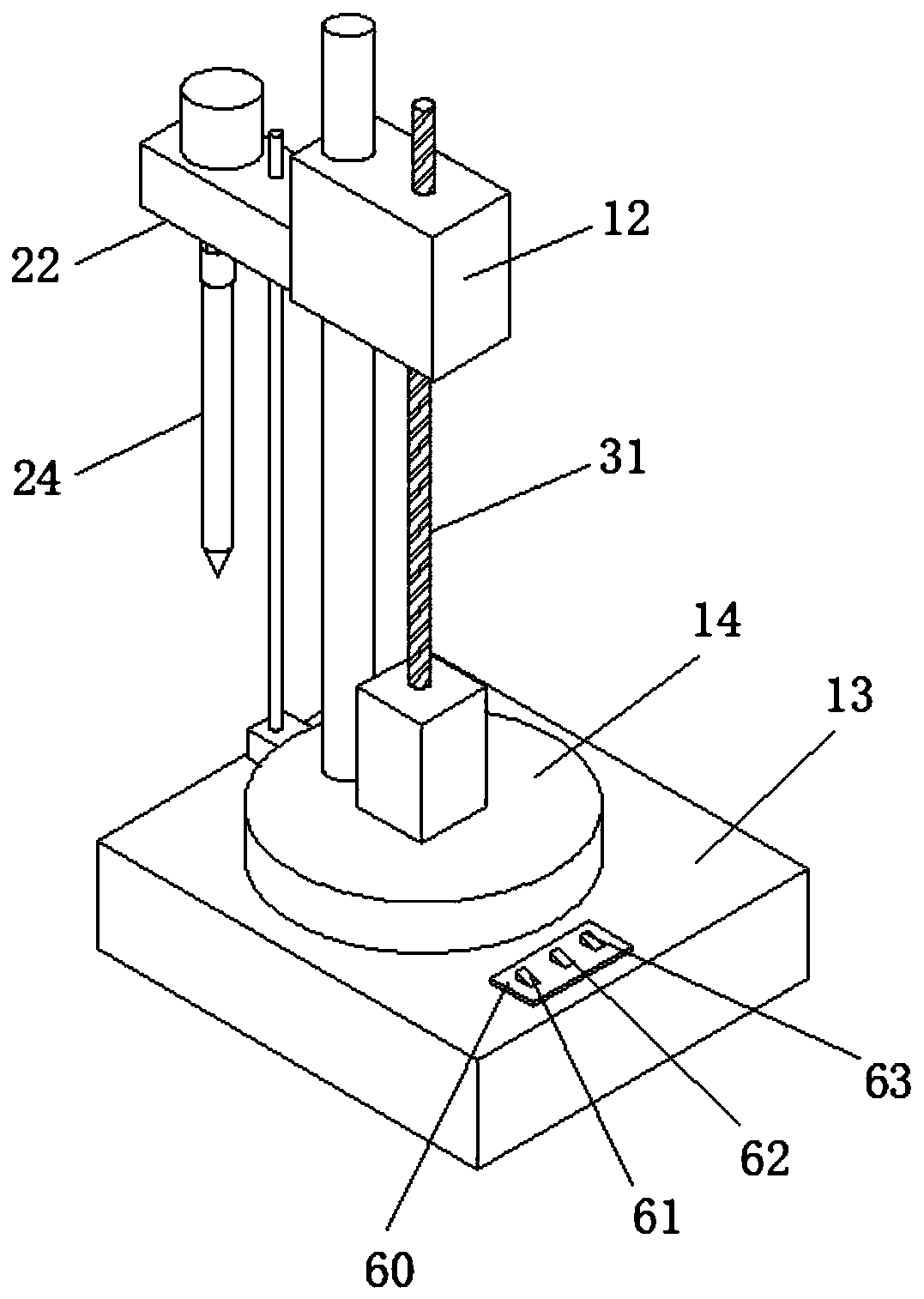

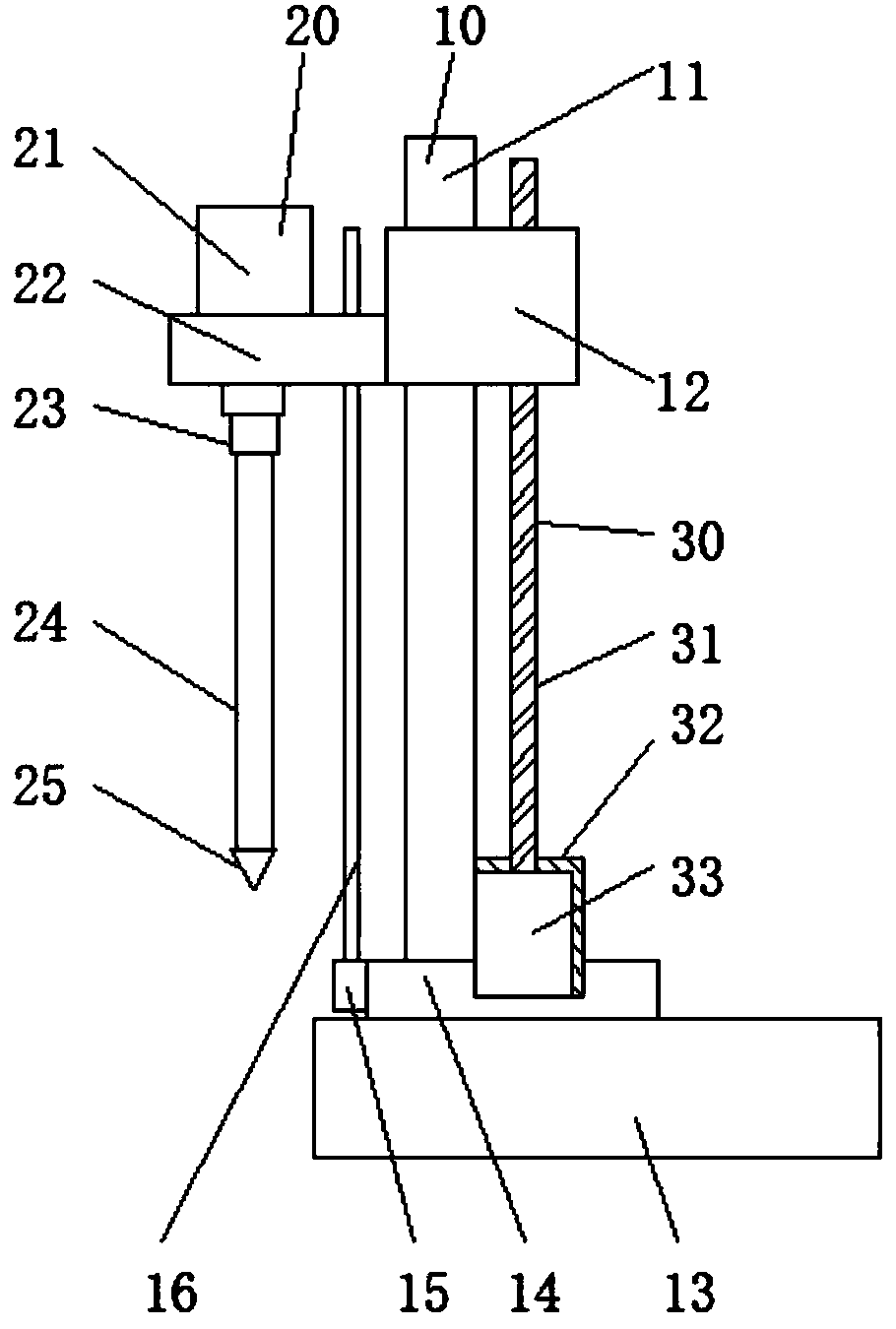

[0032] See Figure 1-4 , The present invention provides a directional adjustment device for mine drilling, comprising: a main assembly 10, the main assembly 10 includes a fixed column 11, a connecting block 12, a base 13, a plate body 14, a fixed block 15, a sliding rod 16, and a lifting assembly 30 , The drilling assembly 20 and the switch assembly 60;

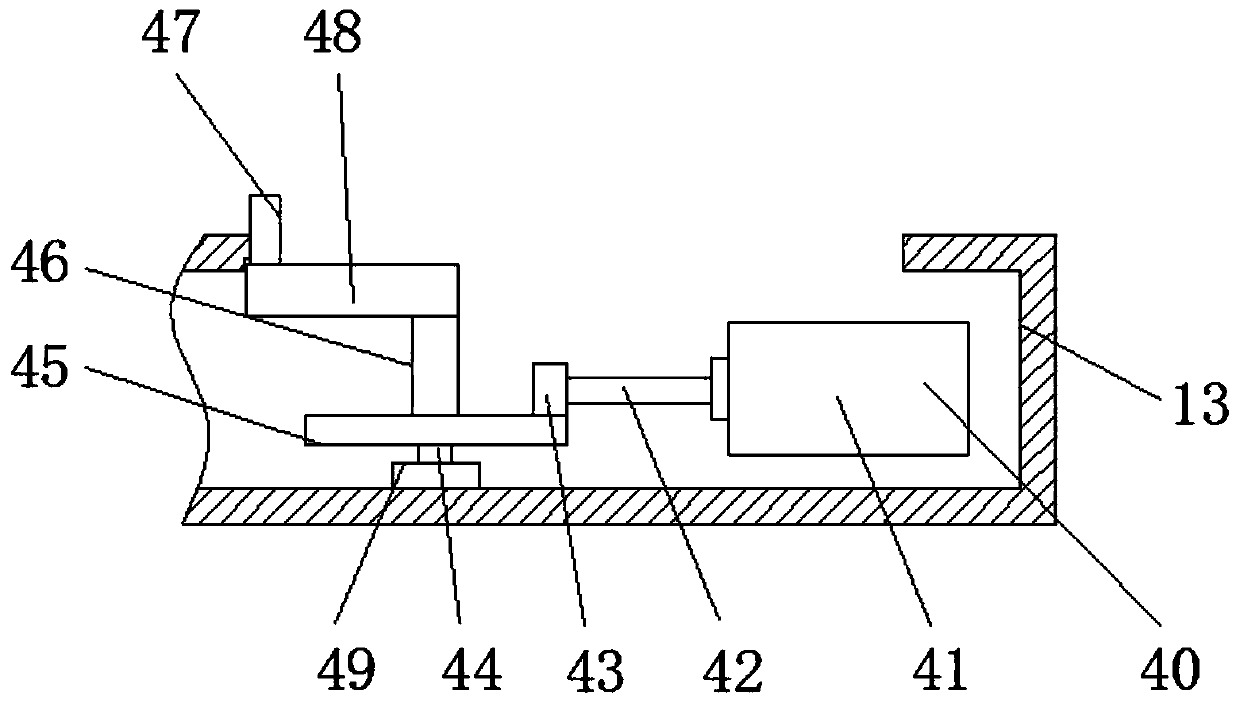

[0033] The drive assembly 40, the drive assembly 40 includes a third motor 41, a first connecting shaft 42, a first gear 43, a second connecting shaft 44, a second gear 45, a first rod 46, a second rod 47, a support plate 48 and a bearing 49. The third motor 41 is installed on the inner side of the base 13, one end of the first connecting shaft 42 is connected to the output shaft of the third motor 41, the first gear 43 is connected to one end of the first gear 43, and the first gear 43 In mesh connection with the second gear 45, one end of the first rod 46 is welded to the outer wall of the second gear 45, the bottom side of t...

Embodiment 2

[0042] The invention provides a method for adjusting a directional adjusting device for mine drilling, which includes the following steps:

[0043] S1. First start the third motor through the third switch, the third motor drives the first connecting shaft to rotate, the first connecting shaft drives the first gear to rotate, and the first gear rotates in the bearing through the second connecting shaft to drive the second gear to rotate;

[0044] S2. When the second gear rotates, the first rod body drives the support plate to rotate, and the second rod body drives the plate body to rotate;

[0045] S3. The plate body drives the drilling assembly and the lifting assembly to rotate through the fixed column and the connecting block to adjust the position of the hole. The angle of the plate rotation adjustment is 20°;

[0046] S4. The second switch starts the rotation of the second motor, and the connecting rod is driven by the second motor and the screw rod to move downwards, so that the c...

Embodiment 3

[0048] The invention provides a method for adjusting a directional adjusting device for mine drilling, which includes the following steps:

[0049] S1. First start the third motor through the third switch, the third motor drives the first connecting shaft to rotate, the first connecting shaft drives the first gear to rotate, and the first gear rotates in the bearing through the second connecting shaft to drive the second gear to rotate;

[0050] S2. When the second gear rotates, the first rod body drives the support plate to rotate, and the second rod body drives the plate body to rotate;

[0051] S3. The plate body drives the drilling assembly and the lifting assembly to rotate through the fixed column and the connecting block to adjust the position of the hole. The angle of the plate rotation adjustment is 90°;

[0052] S4. The second switch starts the rotation of the second motor, and the connecting rod is driven by the second motor and the screw rod to move downwards, so that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com