Spot weld nugget quality evaluation method

A quality evaluation and nugget technology, applied in the direction of photo interpretation, etc., can solve problems such as unfavorable operation, invisible nugget shape in resistance spot welding, and cumbersome evaluation method process, so as to improve evaluation speed, reduce work intensity, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

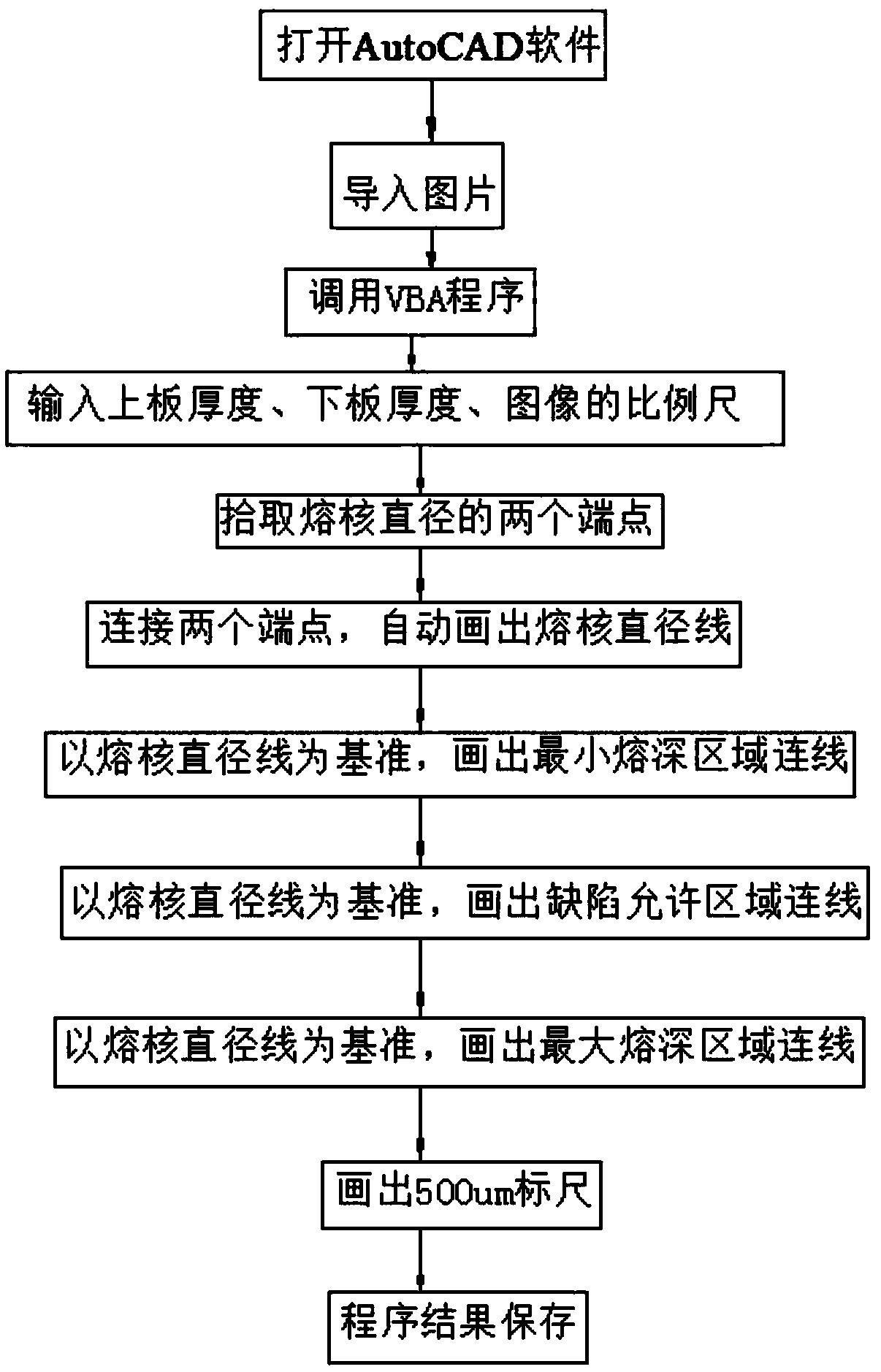

[0055] like image 3 As shown, a method for evaluating the quality of spot welding nuggets includes the following steps:

[0056] Step 1, cut along the center of the spot welding sample, and take a photo to obtain a photo of the nugget morphology (such as figure 1 shown), preferably using a stereo microscope to take pictures to obtain a photo of the shape of the nugget;

[0057] Step 2, the photo is imported into the drawing software, and the VBA program is called; specifically, the drawing software is AutoCAD software, and the method for importing the photo is: open the AutoCAD drawing interface, click "Insert" → "Raster Image Reference" ...", select the photo to be processed, and open it.

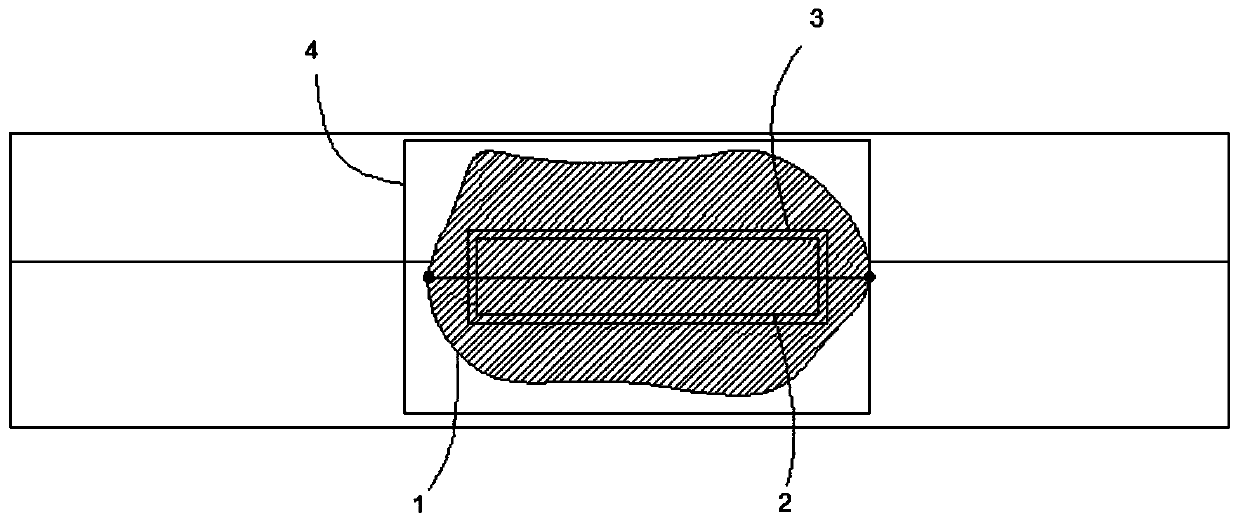

[0058] combine figure 2 As shown, the VBA program does the following:

[0059] S1. Obtain the plate thickness of the upper plate and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com