Application of oxidized cyclodextrin in preparing disintegrants

A technology of cyclodextrin and disintegrant, which is applied in the field of medicine, can solve the problem of less research on cyclodextrin disintegrant, and achieve the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Preparation of oxidized β-cyclodextrin with different oxidation degrees, the quality of β-cyclodextrin used, the volume of hydrogen peroxide and the quality of the final prepared oxidized cyclodextrin are shown in Table 1, and each group is marked as H1 and H2 respectively , H3, H4, H5, H6, H7, H8, H9, H10 were all prepared as follows:

[0021] Dissolve β-cyclodextrin in 20mL of distilled water, then add hydrogen peroxide, shake the reaction at room temperature in a shaking table with a rotation speed of 300r / min and a shaking amplitude of 25mm until the hydrogen peroxide is completely consumed, take out the reaction solution and use ice water as the The washing solution was filtered and washed 5 times to obtain a solid phase, which was dried at 110° C. for 3 hours to obtain an oxidized cyclodextrin.

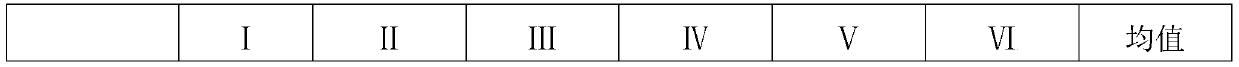

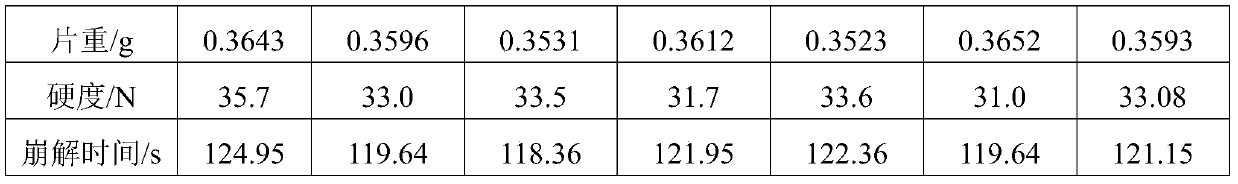

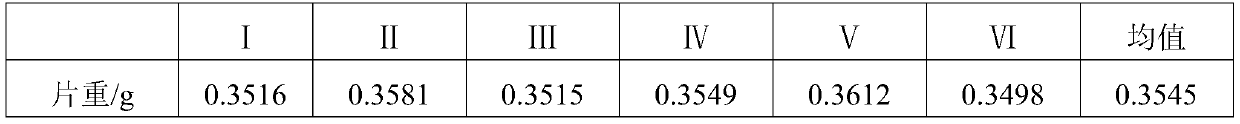

[0022] Table 1

[0023] group β-cyclodextrin (g) Hydrogen peroxide (mL) Oxidized β-cyclodextrin (g) H1 5 0 4.3596 H2 5 0.2 4.4408 H3 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com