Plate paint brushing device for building decoration

A technology for painting and sheet metal, which is applied in the field of sheet metal processing, can solve the problems of easy pollution, pollution of painting equipment, complicated and cumbersome operation, etc., and achieve the effect of realizing recycling, improving drying effect, and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

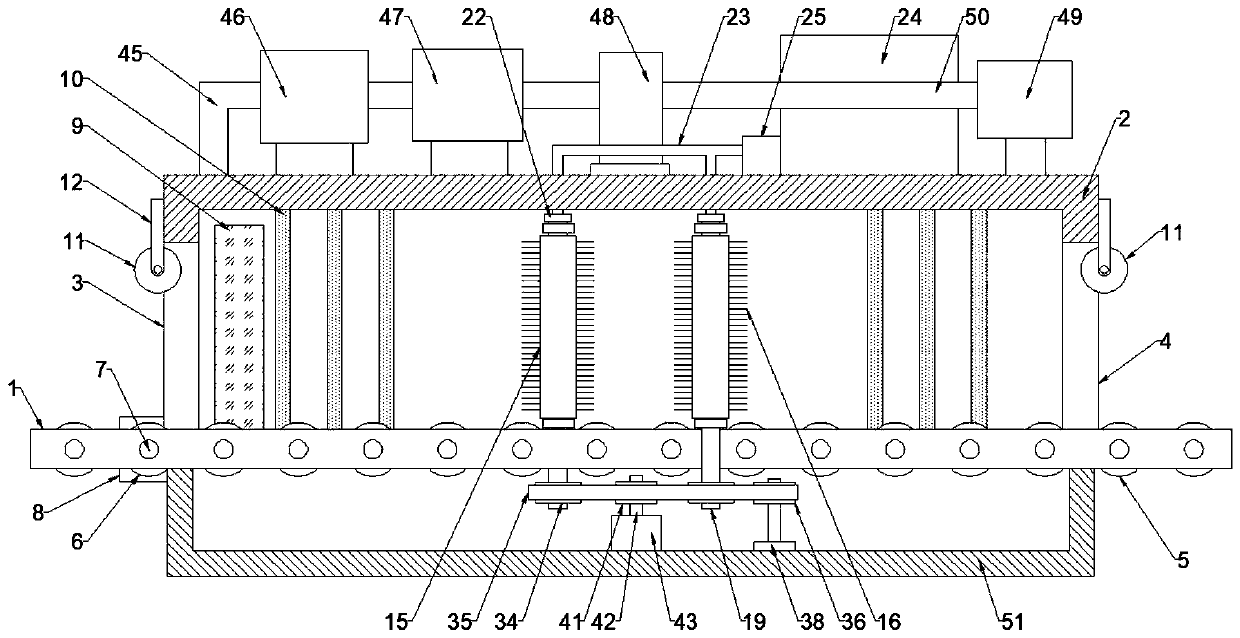

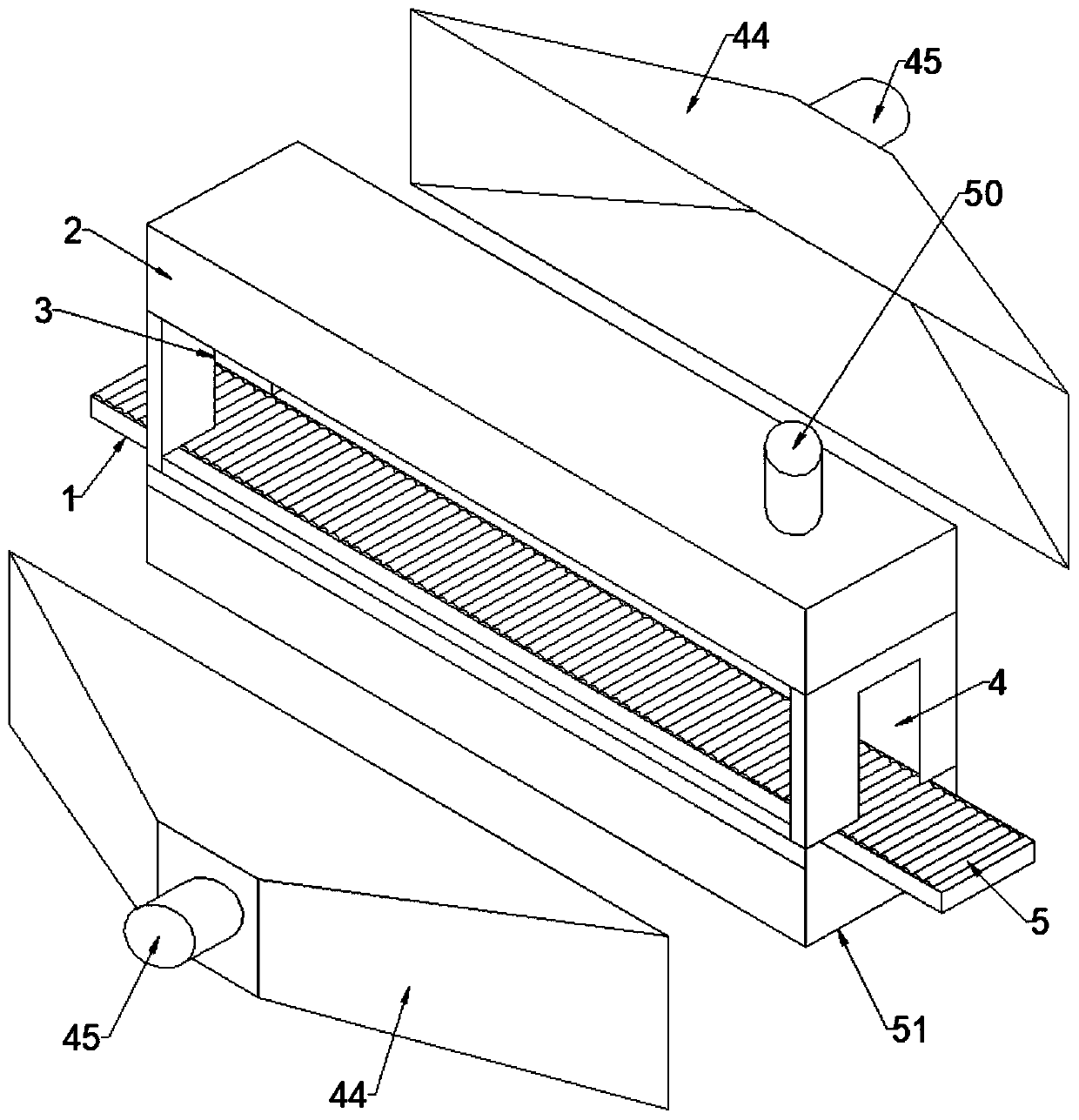

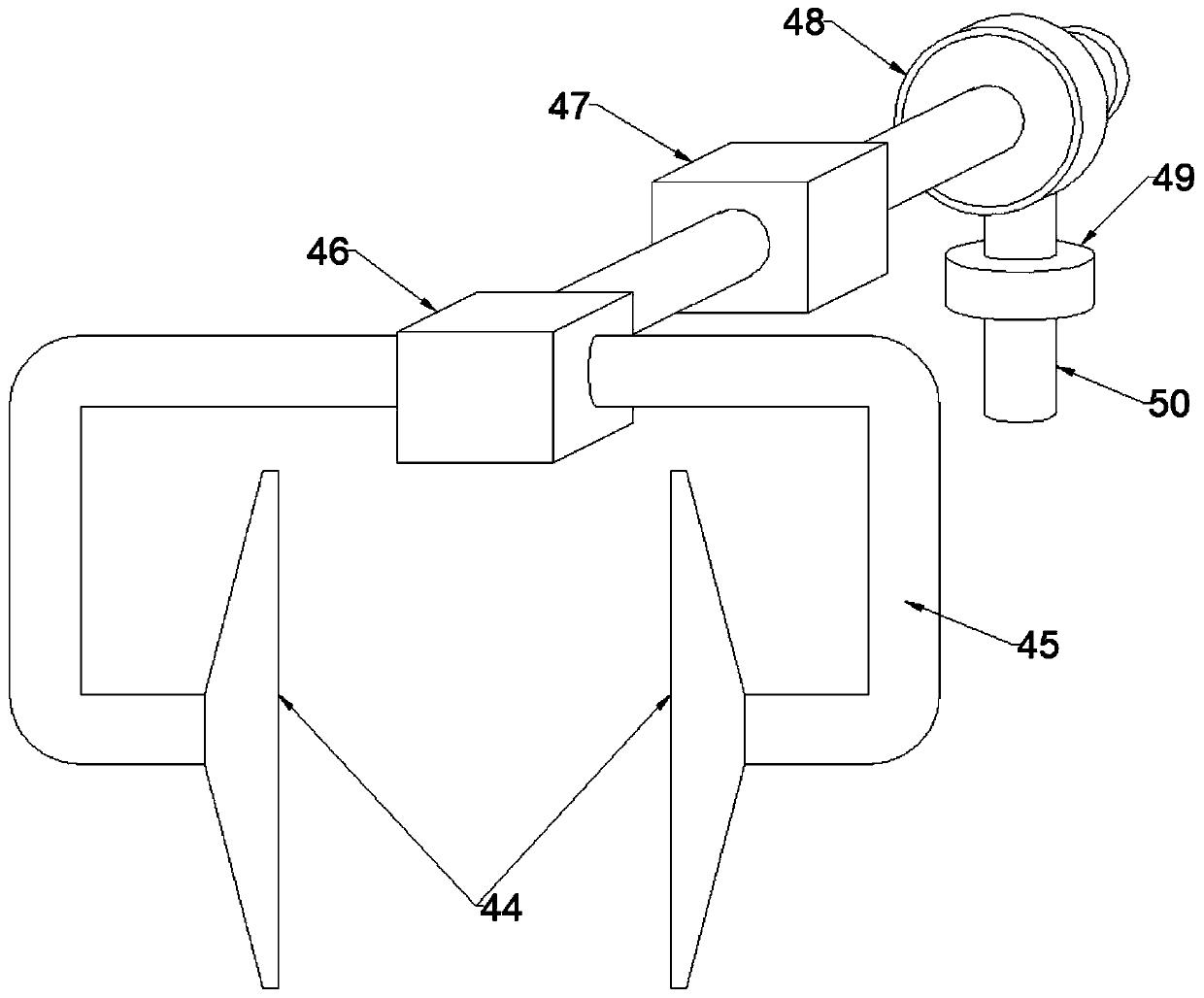

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] see figure 1 Shown, a kind of panel painting device that is used for building decoration, comprises painting frame 1, painting box 2, painting roller 15, paint box 24 and paint collecting box 51, and described painting frame 1 rotates Several transmission rollers 5 are installed, and the roller shafts of the transmission rollers 5 are mounted on the painting frame 1, and the transmission rollers 5 are parallel to each other and distributed at equal intervals, see figure 1 and Figure 4 As shown, a driving roller 6 is also installed on the painting frame 1, the number of the driving roller 6 is at least one, and the driving roller 6 is installed on the driving wheel shaft 7, and one end of the driving wheel shaft 7 passes through the painting frame 1 to connect The motor shaft of the first servo motor 8, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com