Modulating pulse current welding method and system of aluminum alloy thin plate and storage medium

A technology of modulating pulses and welding methods, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of easy welding of thin plates, easy welding of base materials, poor application effect, etc., and achieve good welds. Forming effect, strong droplet transition regularity, and favorable effect of bubble escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description. For the step numbers in the embodiment of the present invention, it is only set for the convenience of explanation and description, and there is no limitation on the order of the steps. The execution order of each step in the embodiment can be carried out according to the understanding of those skilled in the art Adaptive adjustment.

[0052] refer to Figure 7 , an embodiment of the present invention provides a modulated pulse current welding method for an aluminum alloy sheet, comprising the following steps:

[0053] Calculate the welding peak current based on the standard formula of parabolic function;

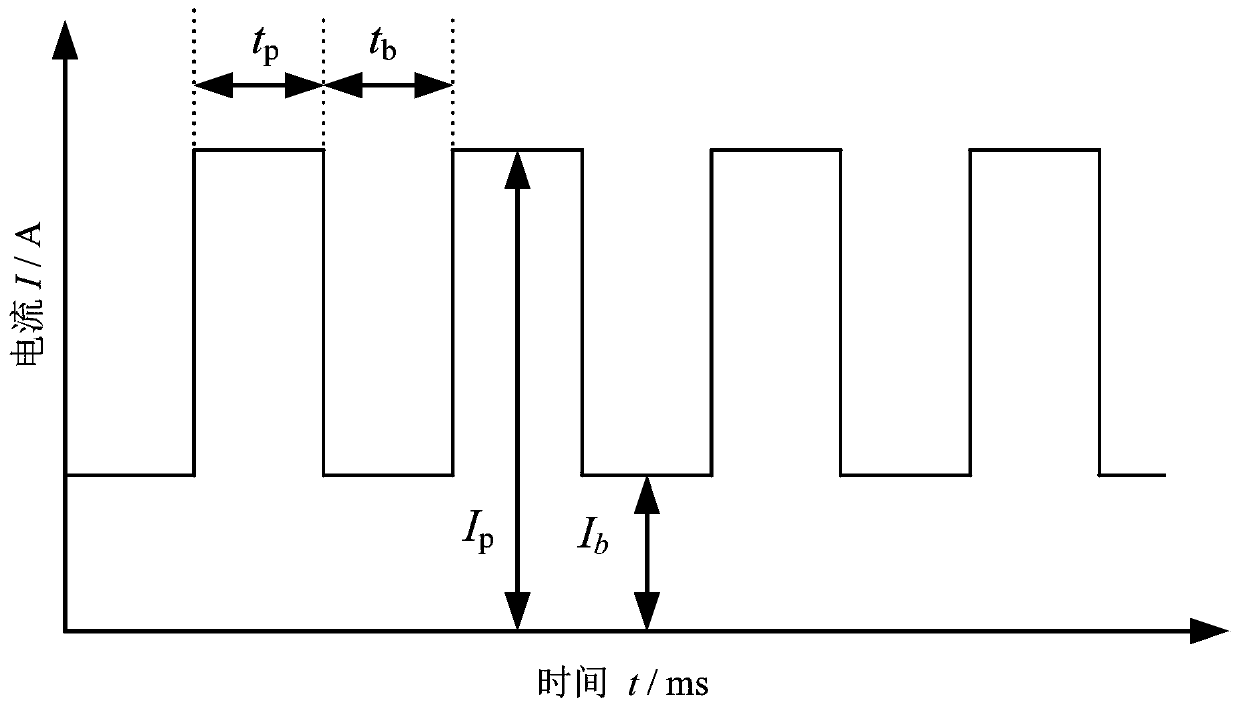

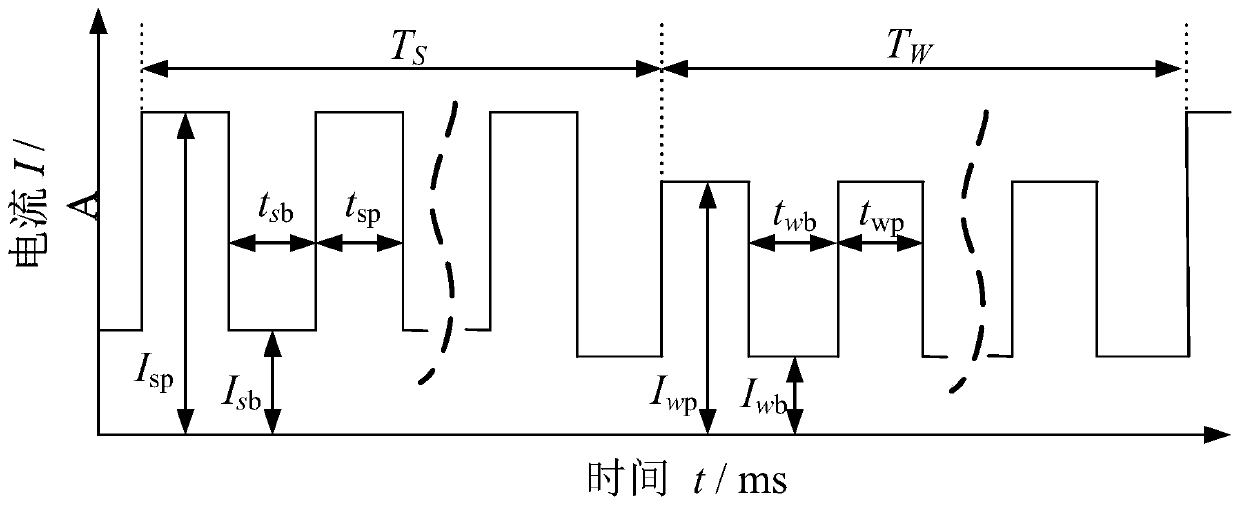

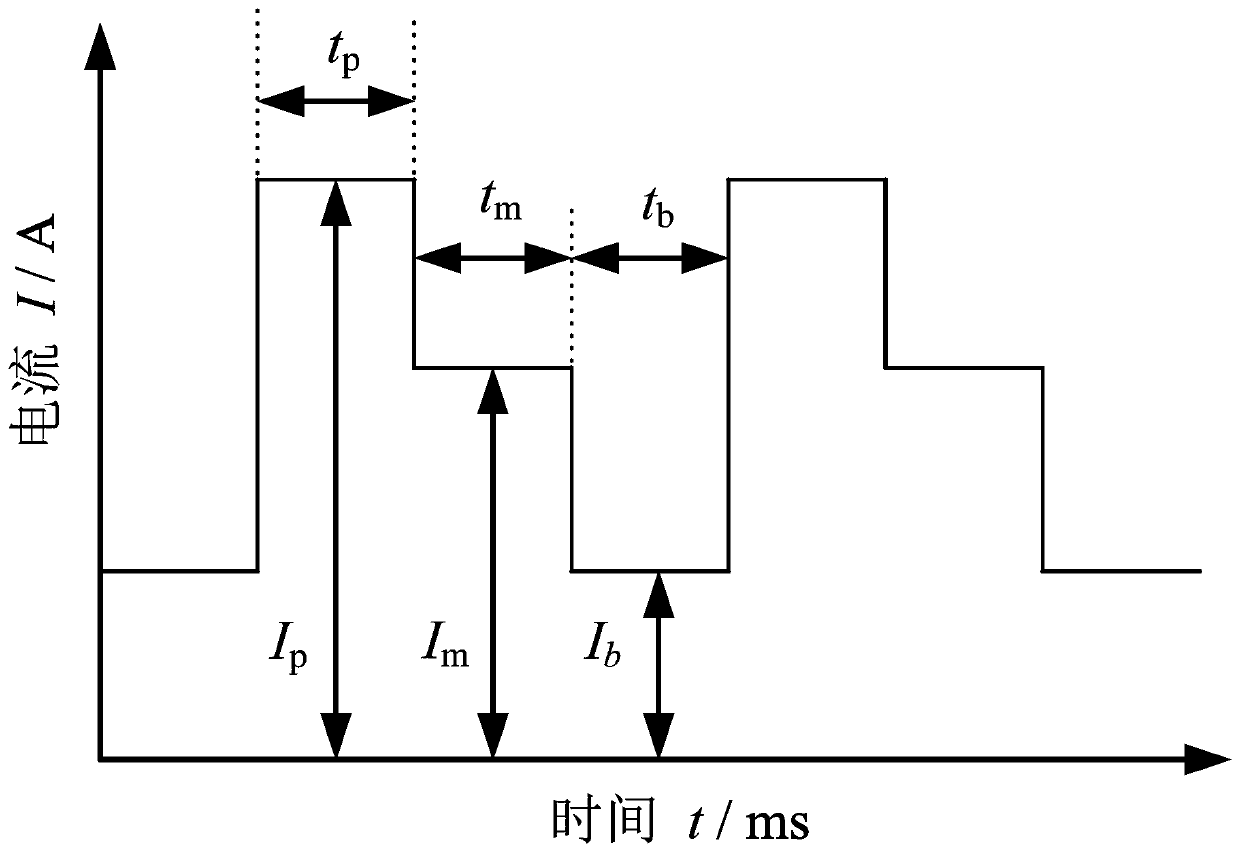

[0054] Configure welding parameters, the welding parameters include welding initial current, ladder pulse current, single pulse base value current, single pulse peak time length, ladder pulse time length, sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com