Nanocomposite conductive adhesive hydrogel and its preparation method and application

A conductive adhesion and nano-composite technology, applied in the field of flexible sensors, can solve the problems of non-spontaneous adhesion and poor deformation ability, and achieve the effects of improving stability, good tensile deformation performance, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

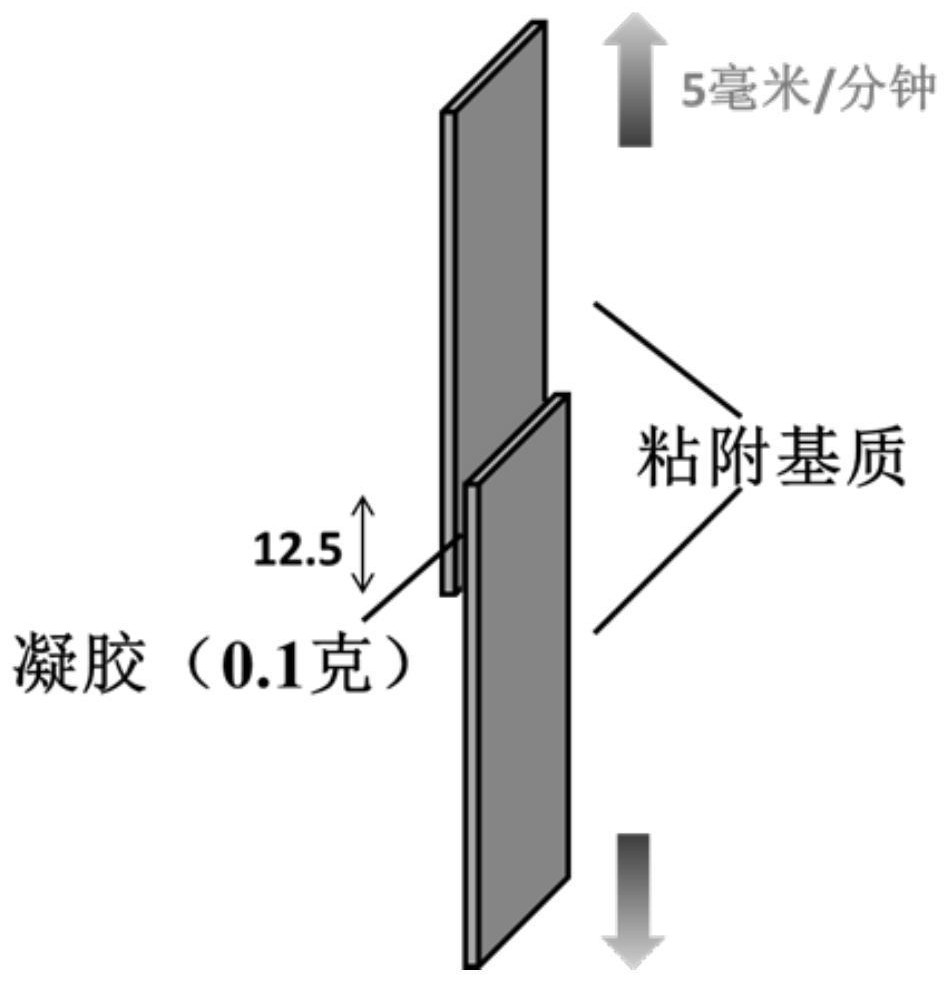

[0045] The embodiment of the present invention proposes a method for preparing a nanocomposite conductive adhesive hydrogel, comprising the following steps:

[0046] (a) mixing cationic monomers, photoinitiators, anionic components, sulfonated MXene nanoparticles, and water to obtain a precursor solution;

[0047] (b) degassing the above precursor solution;

[0048] (c) irradiating the precursor solution obtained in step (b) with ultraviolet light to initiate cationic monomer polymerization, and the produced cationic monomer polymer interacts with anionic components and nanoparticles to form a hydrogel;

[0049] Wherein, in step (a), the anion component includes glycosaminoglycan and its derivatives.

[0050] The embodiment of the present invention adds cationic monomers and their photoinitiators, anionic components, and sulfonated MXene nanoparticles. Under ultraviolet light triggering, cationic monomers polymerize to form long-chain cationic polymers, while anionic componen...

Embodiment 1

[0098] Example 1 Preparation of Conductive Adhesive Hydrogels

[0099] 1)Na + Preparation of intercalated MXene: Mix 10ml of 9mol / L hydrochloric acid solution with 0.5g of lithium fluoride powder, stir for 5 minutes to obtain an etching solution, add 0.5g of titanium aluminum carbide powder to the etching solution and seal the container, at 35°C Stir for 24 hours for etching; after the etching, centrifuge at 12000 rpm for 5 minutes, pour off the supernatant, then add deionized water to wash, repeat the above steps 8-10 times; after pouring the supernatant for the last time, pour the suspension Add a small amount of 5wt% dilute sodium hydroxide solution and stir for 2 hours, then wash the precipitated powder with a large amount of deionized water until the pH of the centrifuged solution is 7-8, and disperse the obtained slurry into a small amount of deionized water spare;

[0100] 2) Synthesis of sulfanilic acid diazonium salt: suspend 2.1g sulfanilic acid in 10ml deionized...

Embodiment 2

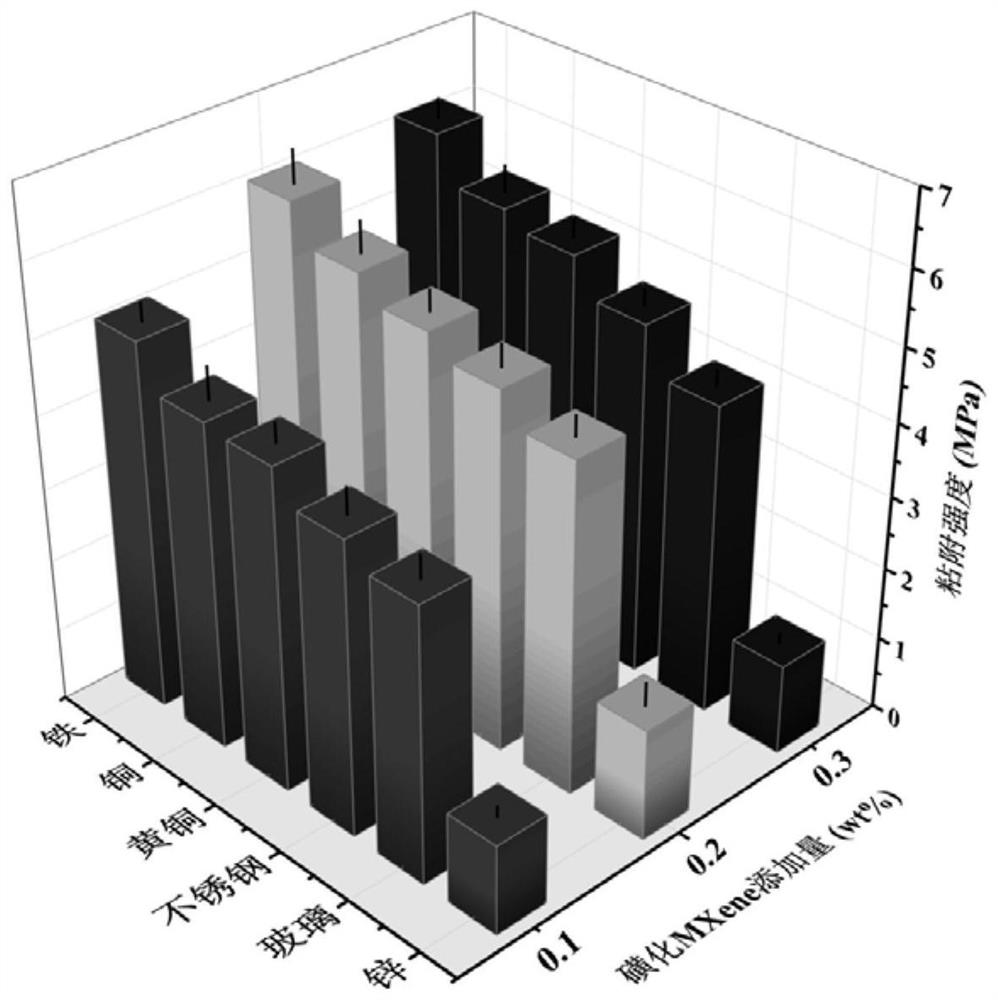

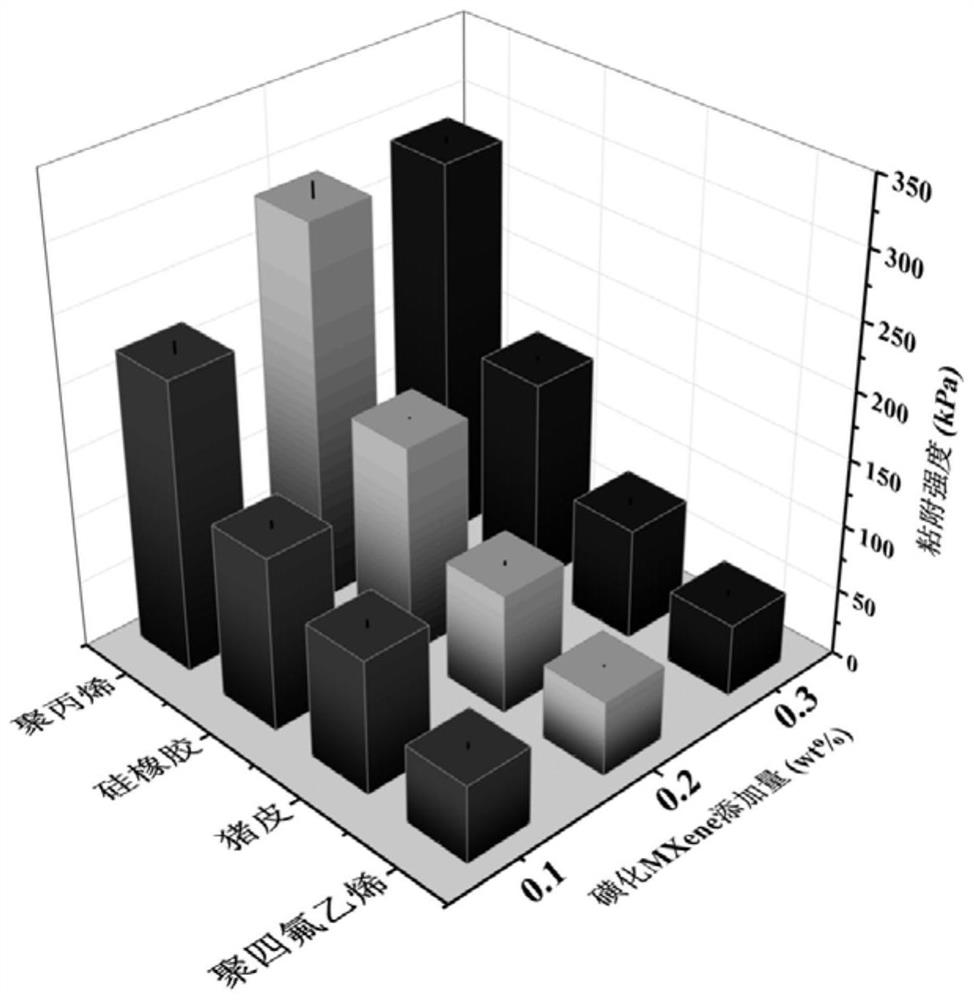

[0106] Example 2 Preparation of Conductive Adhesive Hydrogels

[0107] Same as Example 1, the difference is that in step 4), the concentration of nanoparticles is 0.2wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com