Heat treatment optimization method for carburized steel bearing rings

A technology of bearing rings and optimization methods, which is applied in the field of heat treatment, can solve problems such as time-consuming, labor-intensive and cost-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

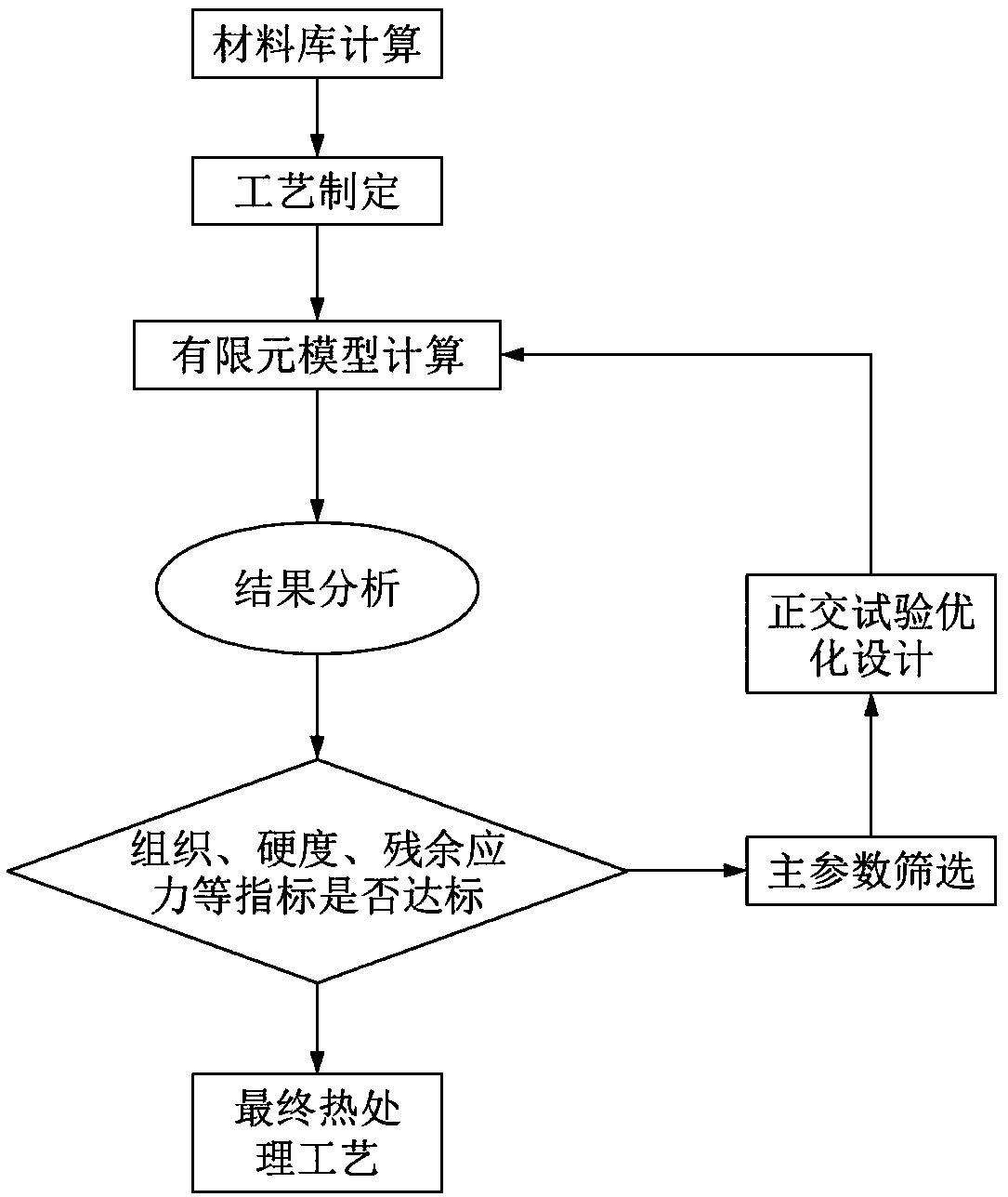

[0027] The invention provides a heat treatment optimization method for a carburized steel bearing ring, comprising the following steps:

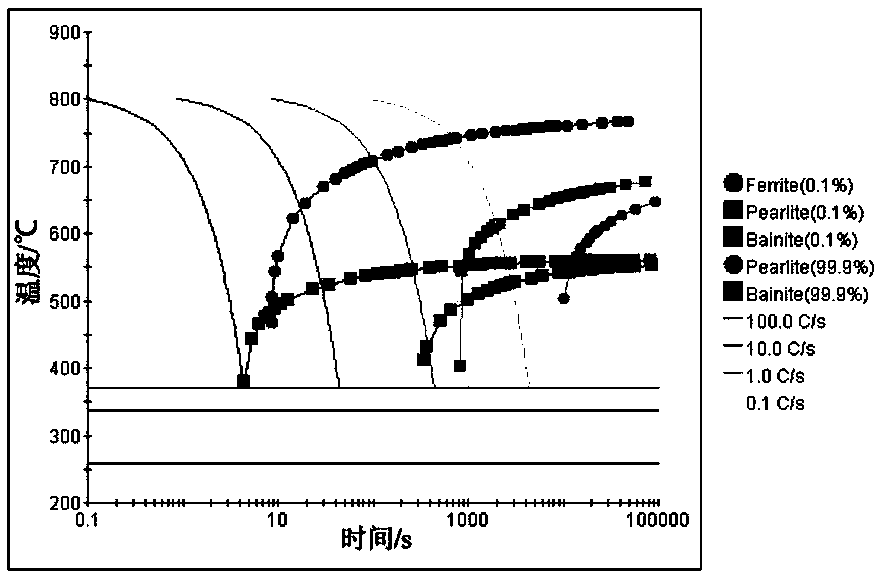

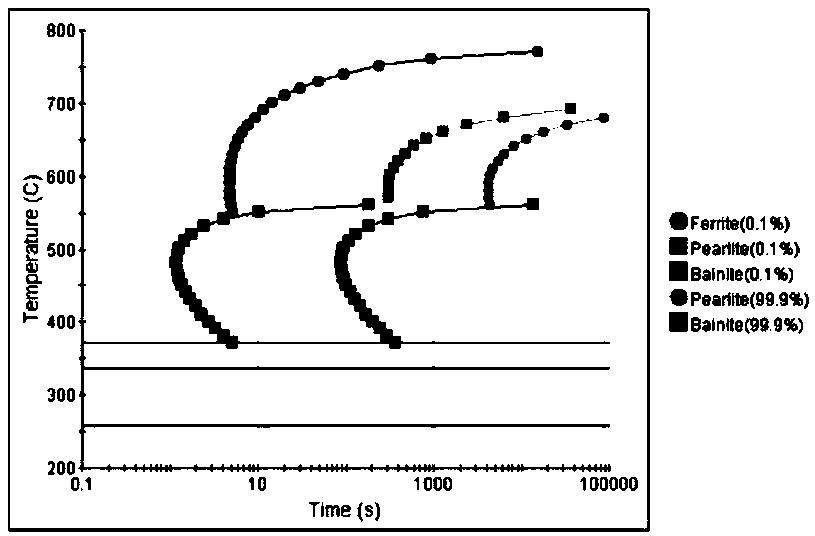

[0028] 1) Obtain thermal property curve, CCT curve, TTT curve and hardenability curve according to the chemical composition content of carburizing steel;

[0029] 2) According to the thermophysical performance curve, CCT curve, TTT curve and hardenability curve and the established initial heat treatment process, the heat treatment simulation model under the coupling of temperature field, tissue field and stress field of carburized steel bearing ring is established, and the carburizing The heat treatment process of cooling, quenching and tempering of the steel bearing ring is simulated. After the simulation of the heat treatment process is completed, the martensite, hardness, carburized layer and stress tracking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com