Combined water blocking structure for buried type pressure steel tube

A penstock, buried technology, applied in pipes, hydroelectric power generation, water conservancy projects, etc., can solve the problems affecting engineering benefits, water seepage in the side walls of the workshop, and internal water seepage, etc., to achieve simple and convenient operation process, reduce operating costs, The effect of reducing external water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

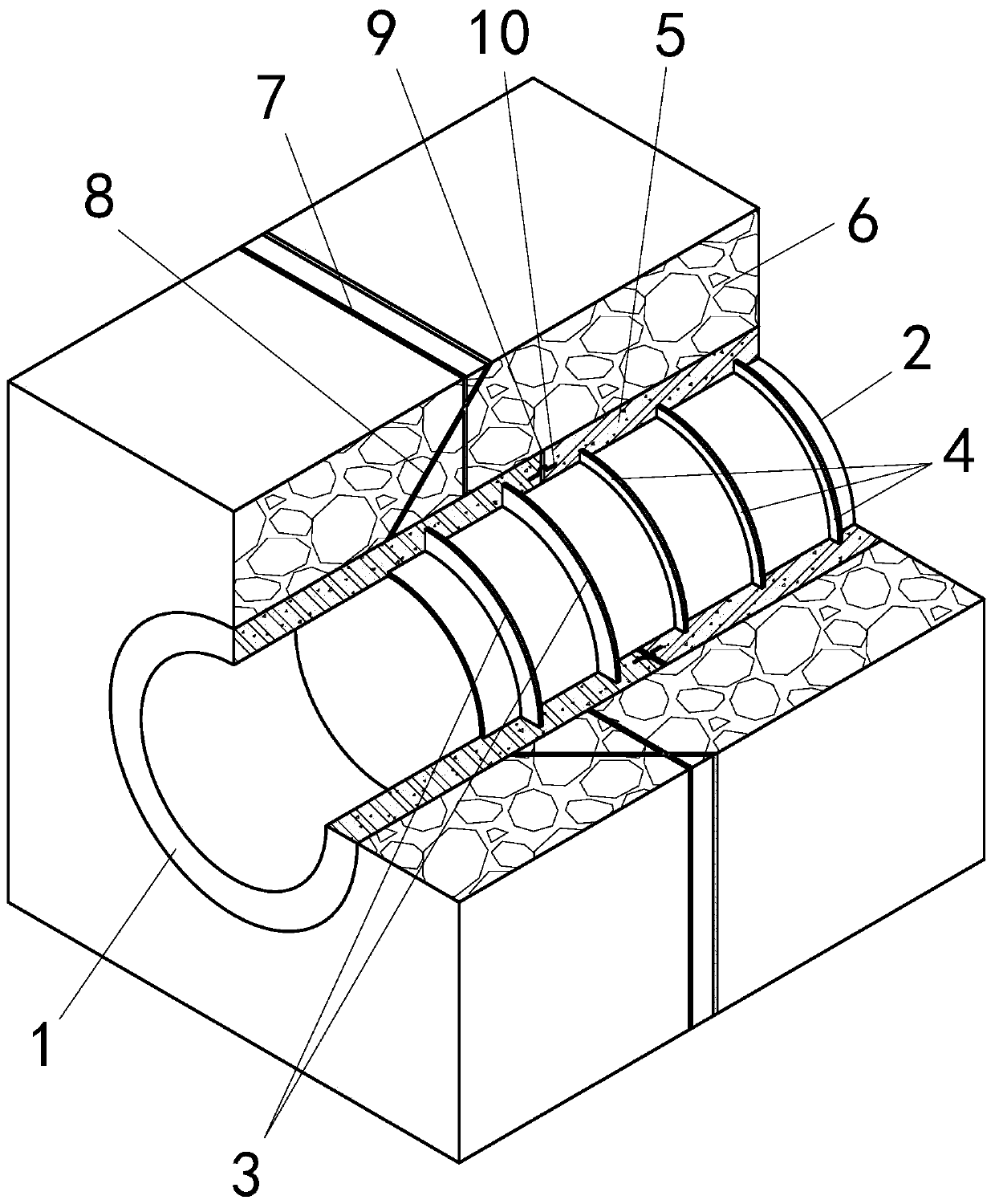

[0016] The following is an example of the combined water blocking structure of buried penstock steel pipes in the diversion power generation system of Dongqing Hydropower Station in Beipanjiang, Guizhou. The specific construction is as follows: figure 1 As shown, in this example, firstly, the structure of the penstock 2 is optimized, specifically, a group of water blocking rings 3 are welded at the water inlet end of the penstock 2 . The water seepage in the reinforced concrete tunnel 1 is blocked by the water blocking ring 3, or the seepage path is extended, so as to reduce the external water pressure of the penstock 2. The rest of the penstock 2 behind the water blocking ring 3 is welded with a set of stiffening rings 4 arranged at equal intervals to strengthen the compressive strength of the penstock 2 . Secondly, the permanent deformation joint 9 and the copper sheet water stop 10 are set at the boundary between the reinforced concrete tunnel 1 and the backfilled concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com