Food processor capable of adjusting temperature

A food processing machine, adjustable technology, applied in dryers, lighting and heating equipment, drying solid materials, etc., can solve the problems of slow drying efficiency, reduce moisture, increase hot air drying area, and avoid contamination of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

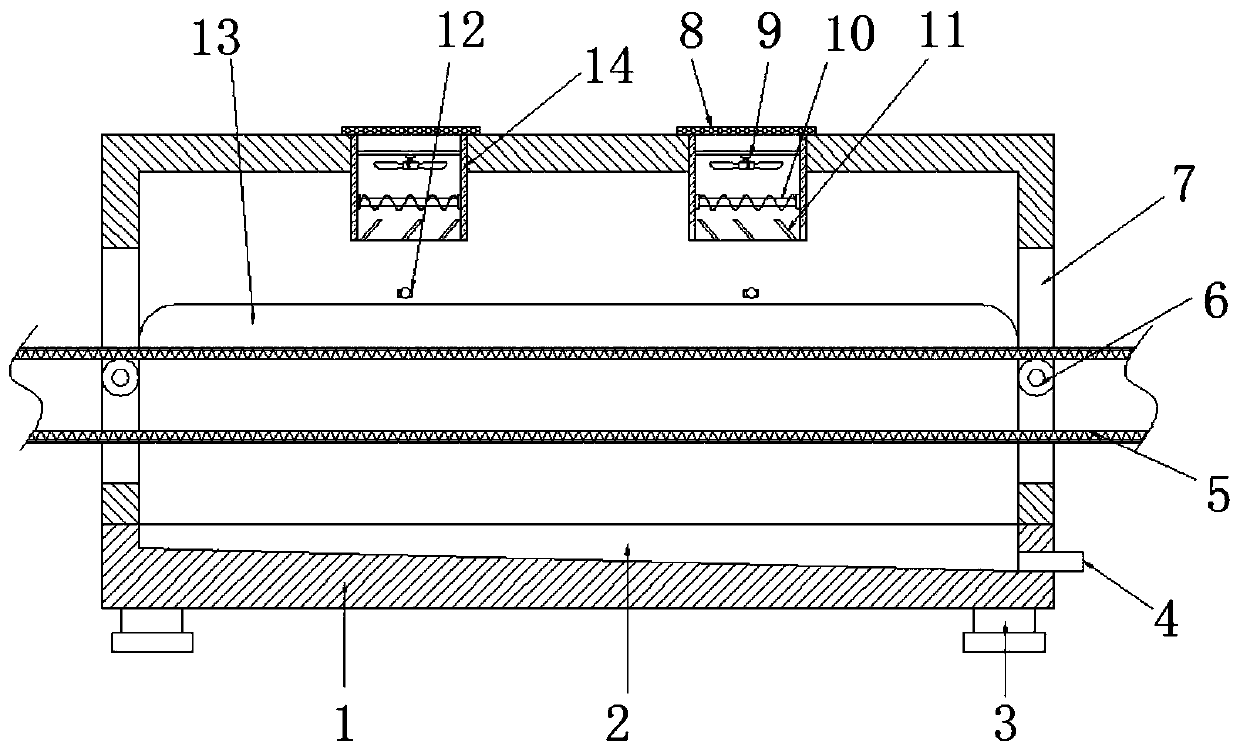

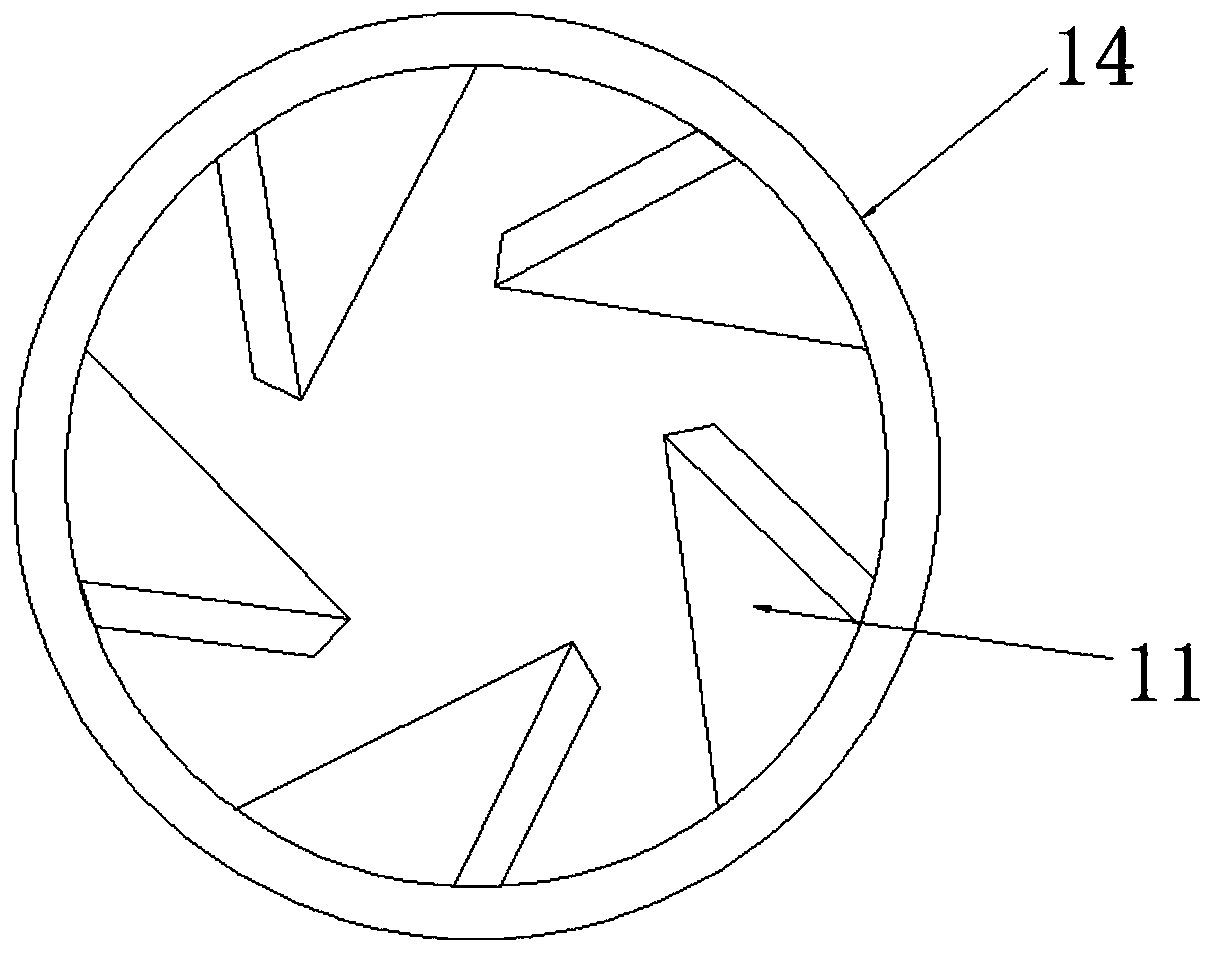

[0024] refer to figure 1 with figure 2 , a temperature-adjustable food processing machine, comprising a box body 1, a material delivery port 7 is opened on the outer wall of the opposite side of the box body 1, and the same conveyor track 5 runs through the two material delivery ports 7, and the conveyor track 5 is two The end transmission is equipped with a driving mechanism, and there are two installation openings on the outer wall of the top of the box body 1, and an air duct 14 is fixed in the installation opening, and a fan 9 and a plurality of electric heating wires 10 are fixed in the air duct 14, and the fan 9 is located in the electric heating A temperature sensor 12 is arranged above the wire 10 and below the air duct 14, and the temperature sensor 12 is fixed in the casing 1. The temperature sensor 12 is connected to a controller through a signal line, and the controller is electrically connected to the electric heating wire 10 and the blower fan 9 through the sign...

Embodiment 2

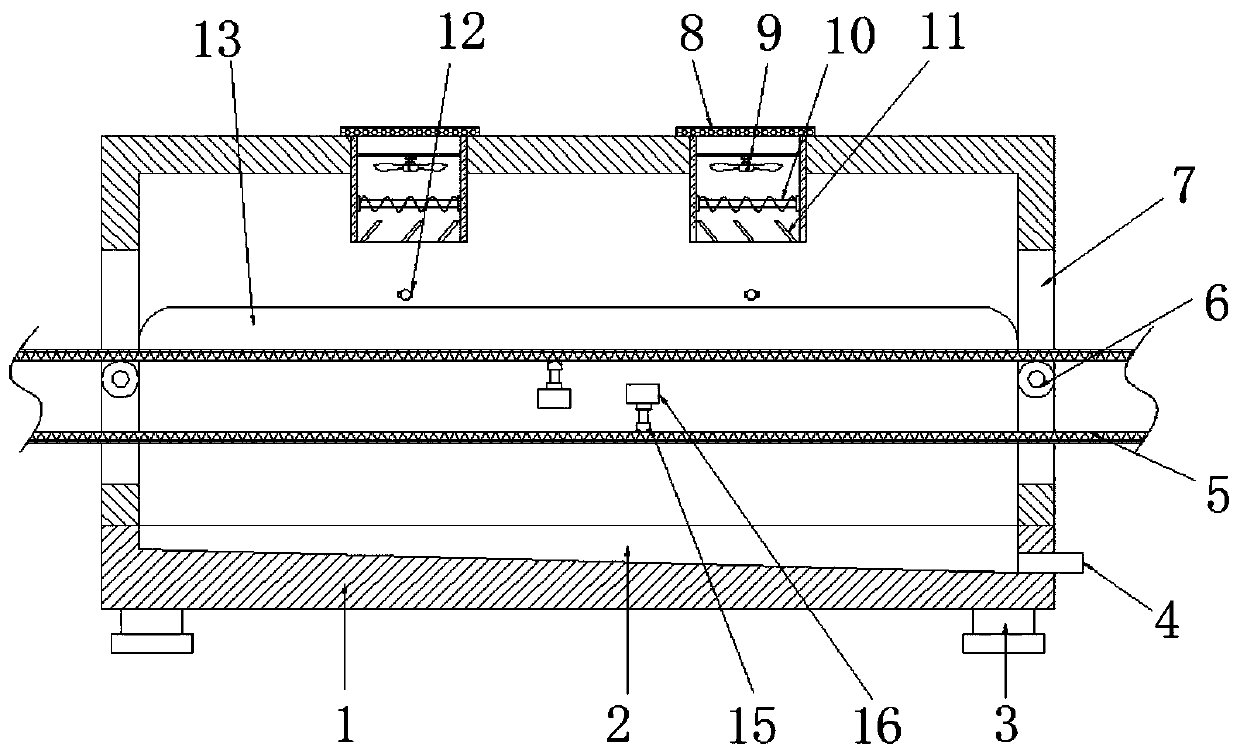

[0028] refer to image 3 , a temperature-adjustable food processor. The difference between this embodiment and Embodiment 1 is that two push rod motors 16 are fixed inside the box body 1, and the output shafts of the two push rod motors 16 are sleeved with rubber Block 15, two rubber blocks 15 are respectively in contact with the upper surface and the lower surface inside the conveyor belt 5 .

[0029] The working principle of this embodiment: the push rod motor 16 can drive the rubber block 15 to move up and down, and the rubber block 15 collides with the transmission track 5 during the up and down movement, so that the water adhered to the transmission track 5 shakes off, reducing the adhesion on the transmission track 5 of moisture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com