Device for improving signal to noise ratio of inductosyn signal

A technology of inductive synchronizer and signal-to-noise ratio, which is applied in the direction of using electrical devices, measuring devices, and amplifiers with only semiconductor devices, etc., which can solve the problem of serious pre-amplifier interference, difficulty in obtaining angle measurement data, and increased high-order harmonic components and other problems to achieve high accuracy, filter out electromagnetic interference, and eliminate angle measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

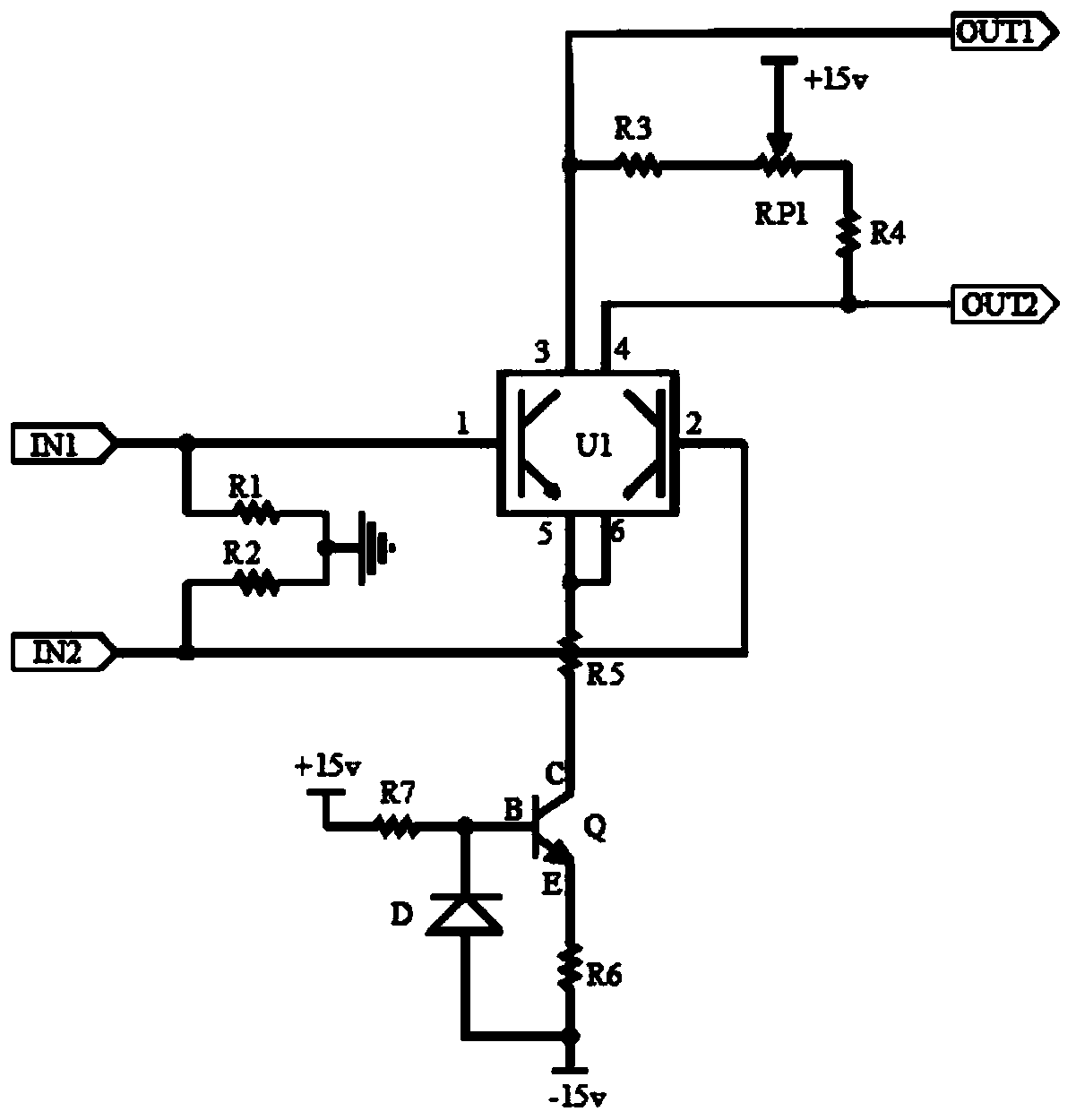

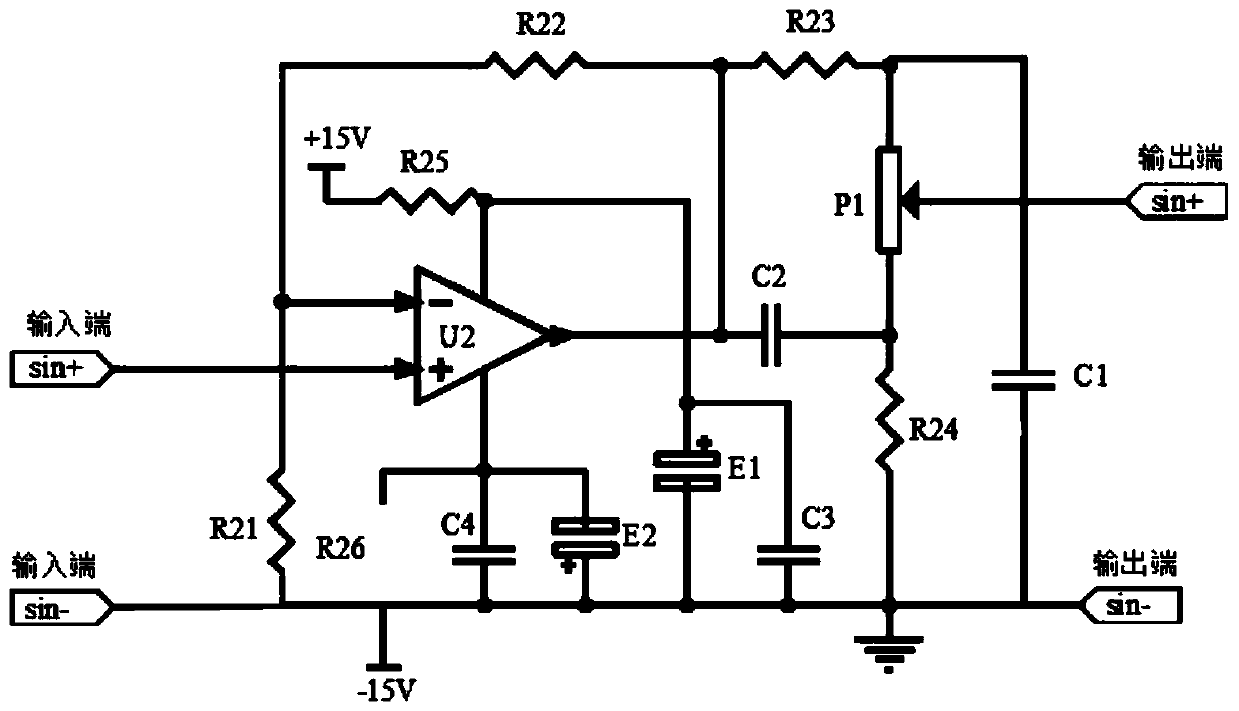

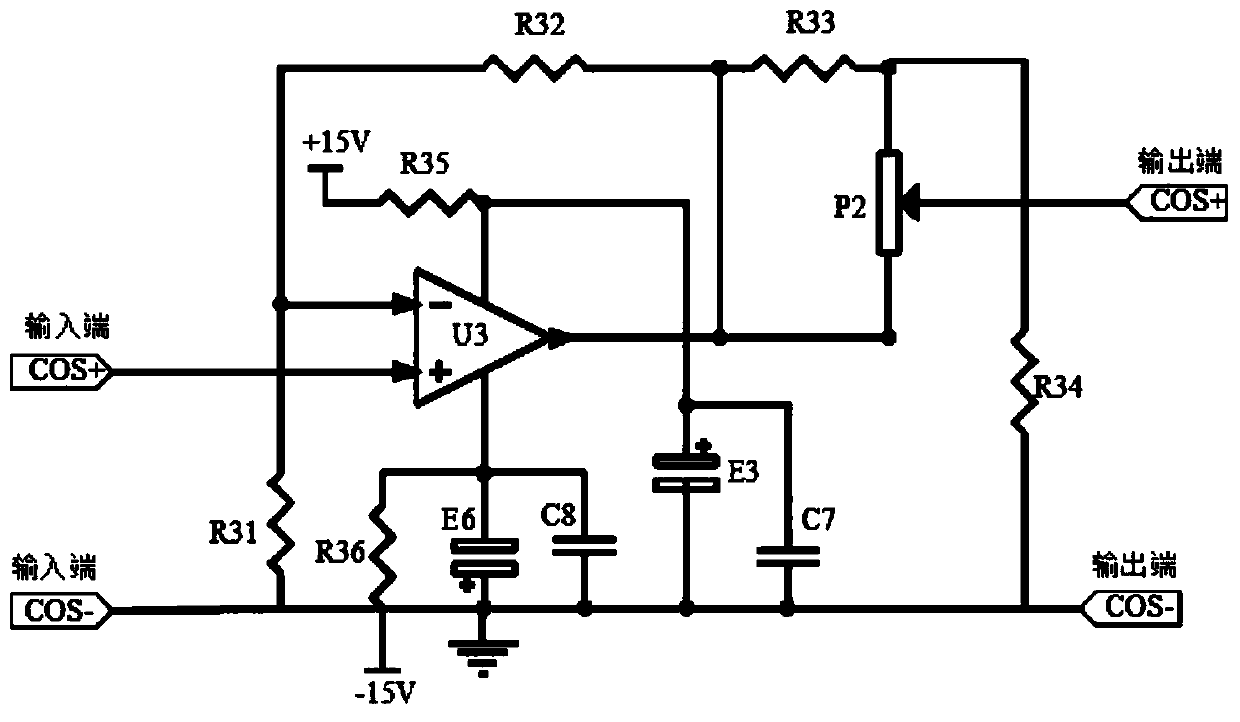

[0027] The present invention adopts a high-precision matching tube and a constant current source circuit to form a pre-amplifier, performs pre-amplification on the output signal of the inductive synchronizer, and uses a high-precision operational amplifier as the second-stage amplifier to perform sine and cosine signals on the inductive synchronizer. Two-stage amplification, and the quadrature adjustment circuit is designed in the sine two-stage amplifier, and the amplitude adjustment circuit is designed in the cosine two-stage amplifier.

[0028] see figure 1 As shown, the embodiment of the present invention provides a device for improving the signal-to-noise ratio of the inductive synchronizer signal, including a preamplifier circuit, a sine secondary amplifying circuit and a cosine secondary amplifying circuit, and the preamplifying circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com