An automatic calibration device for an ultrasonic level meter and its application method

An automatic calibration and ultrasonic technology, applied in the direction of testing/calibration devices, measuring devices, instruments, etc., can solve the problems of poor reproducibility, low precision, inconvenient calibration operation, etc., and achieve the effect of simple operation, high measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described by specific embodiment:

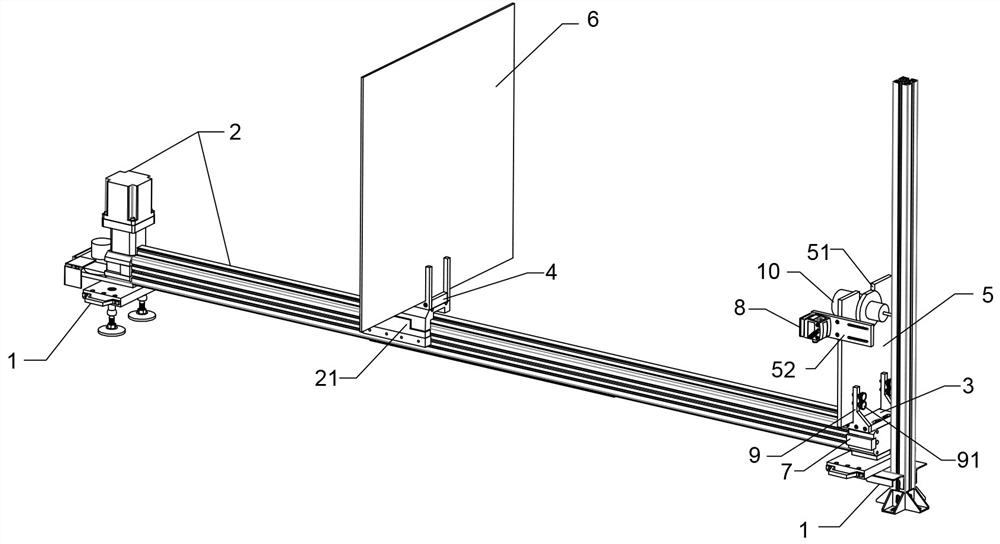

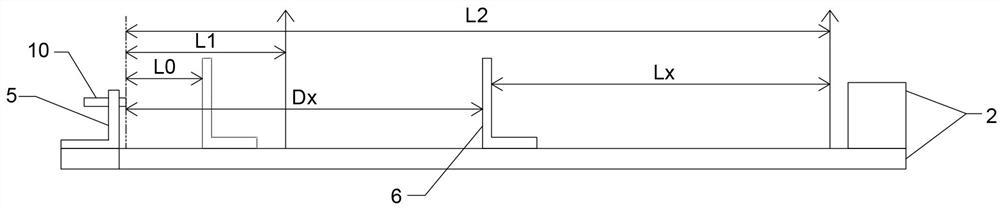

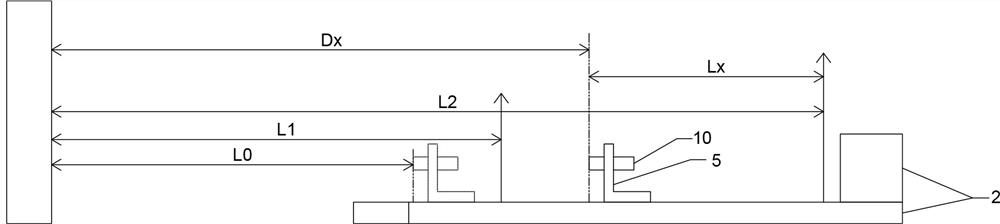

[0036] See figure 1 , an embodiment of an automatic calibration device for an ultrasonic level meter, including a PLC control platform, and also includes an underframe 1, a linear drive module 2, a fixed base 3, a movable base 4, a distance measuring sensor 8, a displacement sensor 7, The probe is installed with a seat plate 5 and an acoustic reflection plate 6, the linear drive module 2 is connected to the base frame 1, the movable base 4 is connected to the linear drive module 2 and driven by it reciprocatingly, and the fixed base 3 is connected to the base frame 1 Above, the fixed base 3 is located on the extension line of the moving path of the movable base 4. In this embodiment, the fixed base 3 is adjacent to the end side of the linear drive module 2. The linear drive module 2, the distance sensor 8. The displacement sensors 7 are electrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com