Method for evaluating influence of cutter deformation on helical milling drilling precision

A helical milling and cutting tool technology, which is applied in the field of evaluation of the impact of tool deformation on helical milling hole-making accuracy, can solve the problem of lack of evaluation methods or techniques for the degree of influence, and achieve the effect of improving hole-making accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

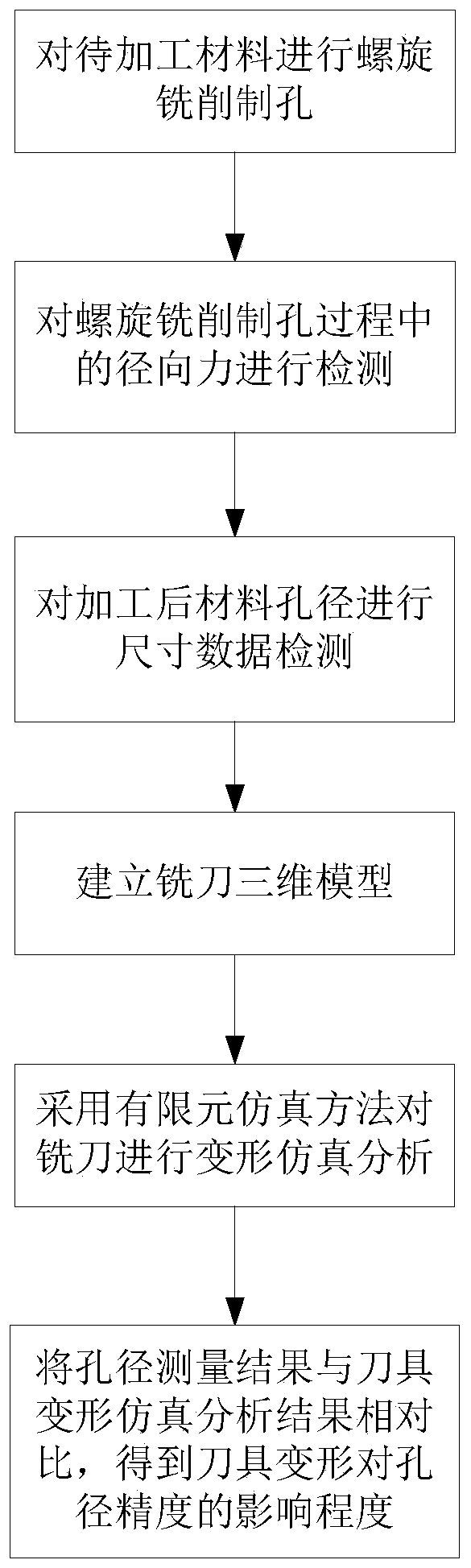

[0032] Such as figure 1 As shown, the method of this embodiment is as follows.

[0033] The invention provides a method for evaluating the influence of tool deformation on the hole making precision of helical milling, comprising the following steps:

[0034] Step 1: use the helical milling method to perform helical milling on the material to be processed;

[0035] Step 2: Detect the radial force during the helical milling hole making process;

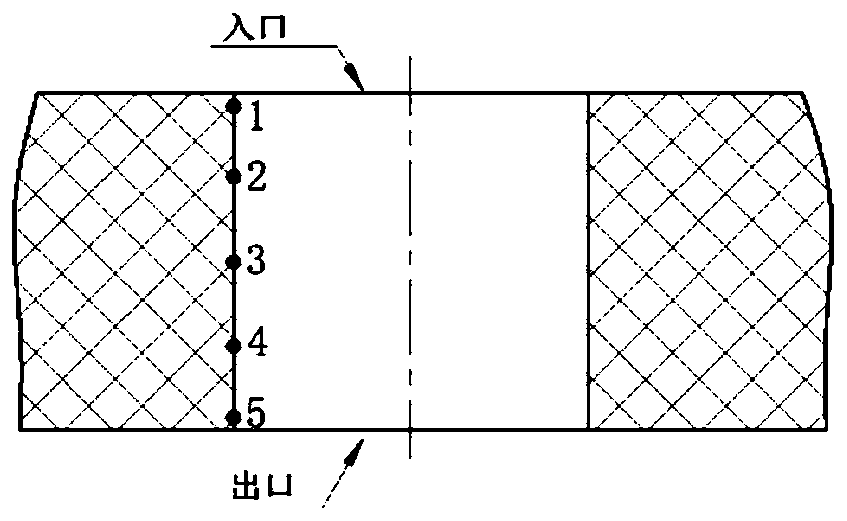

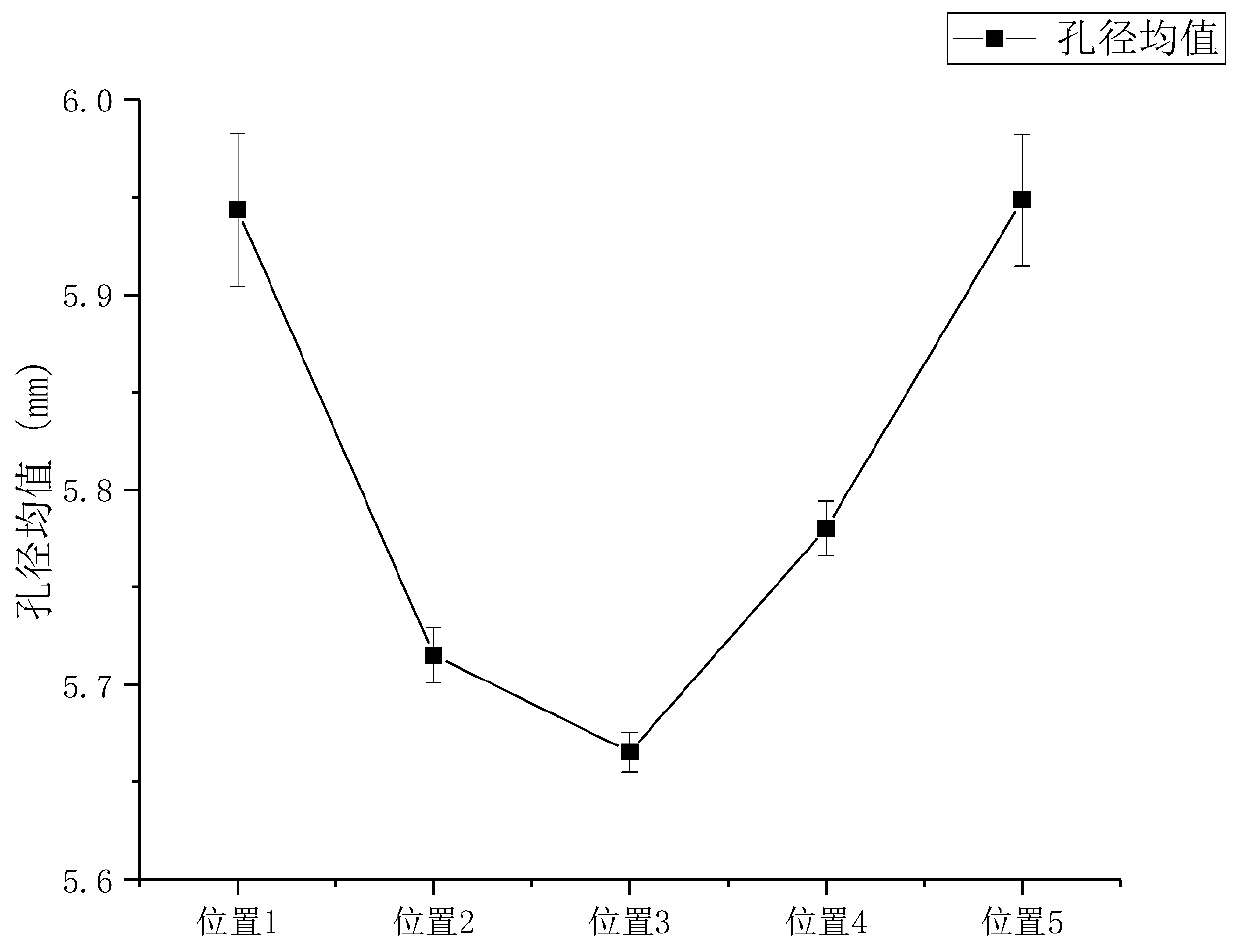

[0036] Step 3: Perform size data detection on the detection position set in the material aperture after helical milling. The detection position setting method is to distribute 5-7 positions evenly between the hole entrance and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com