Adhesive for formaldehyde-free plywood and preparation method thereof, plywood and preparation method thereof

An adhesive and plywood technology, applied in the field of prepared plywood and its preparation, can solve the problems of slow viscosity growth rate and long opening time, and achieve the effect of prolonging the opening time, moderate hot pressing efficiency, and compensating for the decrease of hot pressing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

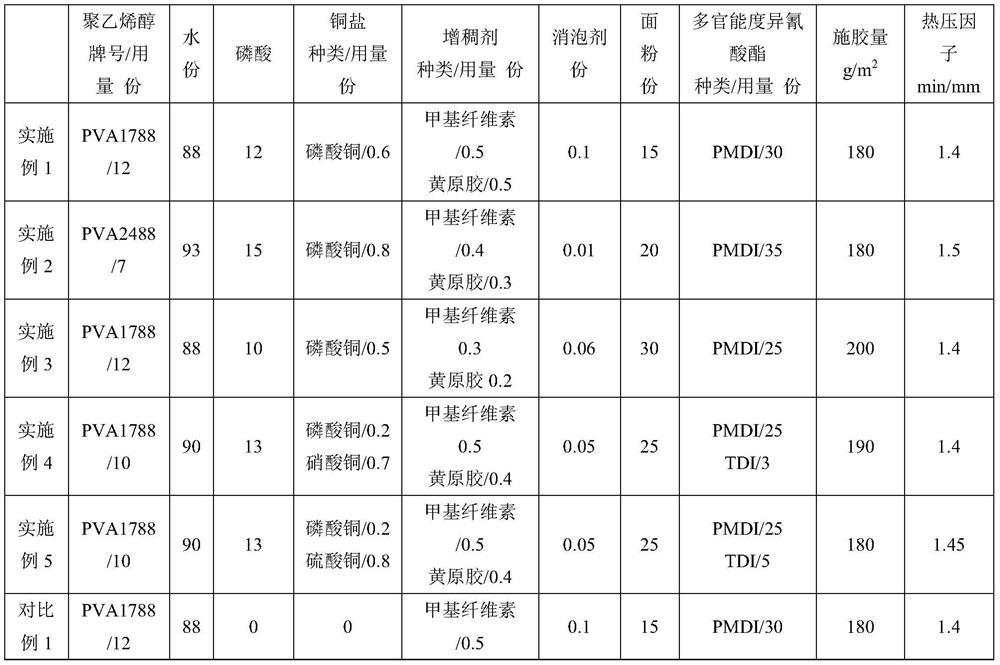

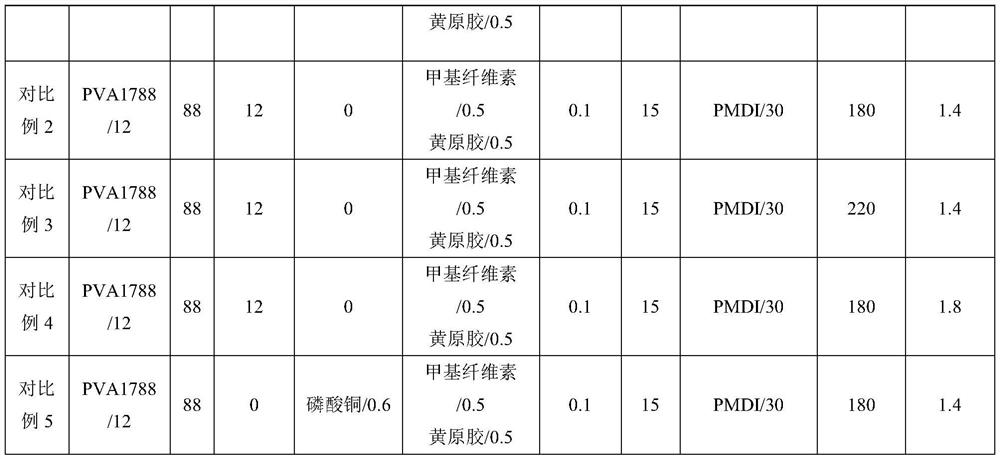

Embodiment 1

[0049] Preparation of adhesives for formaldehyde-free plywood:

[0050] Step 1: Add 88 parts of deionized water and 12 parts of polyvinyl alcohol 1788 into the reaction kettle, stir at room temperature for 20 minutes, then raise the temperature to 90°C and keep it warm for 2 hours to completely dissolve the polyvinyl alcohol, then cool to room temperature stand-by;

[0051] Step 2: Dissolve 0.6 parts of copper phosphate in 12 parts of phosphoric acid.

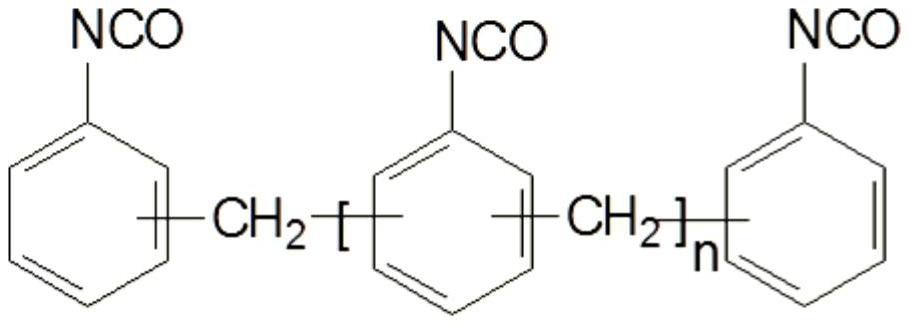

[0052] The third step: the phosphoric acid solution of copper phosphate obtained in the second step and 0.5 parts of xanthan gum, 0.5 parts of methyl cellulose, 0.1 part of defoamer, 15 parts of flour and 30 parts of PMDI are added to the polyethylene obtained in the first step In the alcohol solution, continue to stir at room temperature until the mixture is uniform, and then the formaldehyde-free adhesive for plywood is obtained.

[0053] By testing the viscosity growth of the system, the opening time of the system can be m...

Embodiment 2

[0063] Example 2 Adjust polyvinyl alcohol to 7 parts of PVA2488, water to 93 parts, thickener to 0.4 parts of methylcellulose + 0.3 parts of xanthan gum, defoamer to 0.01 parts, phosphoric acid to 15 parts , the copper phosphate is adjusted to 0.8 parts, the flour is adjusted to 20 parts, the PMDI is adjusted to 35 parts, the hot pressing factor is adjusted to 1.5min / mm, and others are the same as in Example 1;

Embodiment 3

[0064]Example 3 The thickener is adjusted to 0.3 parts of methyl cellulose + 0.2 parts of xanthan gum, the defoamer is adjusted to 0.06 parts, phosphoric acid is adjusted to 10 parts, copper phosphate is adjusted to 0.5 parts, flour is adjusted to 30 parts, PMDI Adjusted to 25 parts, sizing amount adjusted to 200g / m 2 , other with embodiment 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com