Method for determining solubility of pre-oxidized fiber

A technology of pre-oxidized fiber and measurement method, which is applied in the field of carbon fiber, can solve the problems of incomplete dissolution and inaccurate results, and achieve the effects of complete dissolution, accurate results and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The assay method comprises the following steps:

[0035] (1), drying pre-oxidized fiber, weighing:

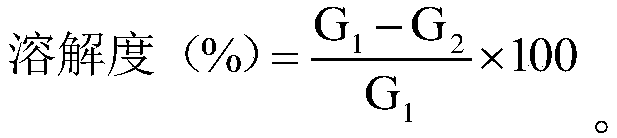

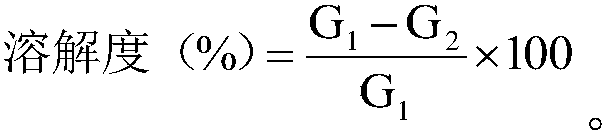

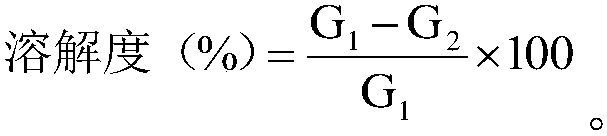

[0036] Weigh about 2.5g of the pre-oxidized wire sample, dry it in a blast drying oven at 120°C for 2 hours, take it out, weigh it and record the accurate result G1(g);

[0037] (2) DMF soaking process:

[0038] a), put the dried pre-oxygenated silk sample into a beaker, add 100mL (95 grams) of DMF solution, place the beaker on a magnetic stirrer and stir for 100min (at room temperature), after the stirring is completed, use a dropper to absorb the soaked liquid, drop it into the desalinated water, and observe whether there are water-insoluble substances.

[0039] b) Take out the sample, wash and soak with new DMF solution (stirring at the same time) for 30 minutes, use a dropper to absorb the soaked liquid and drop it into the desalinated water, and observe whether there are water-insoluble substances.

[0040] c) Place the soaked sample in step b) in a centrifuge tu...

Embodiment 2

[0058] Many people used the same pre-oxygenated silk sample from Lanzhou Bluestar Fiber Co., Ltd., and used the test method of the present invention described in Example 1 to measure the solubility. The specific results are shown in Table 2 below:

[0059] Table 2

[0060]

[0061] (Remarks: Calculate the relative error of each person with the average of all the results (1.717) as the true value)

[0062] From the experimental results of Example 1 and Example 2, it can be seen that using the method of the present invention, the CV value of the result is all small; different personnel use this method to measure, and the results have good consistency.

[0063] The solubility determination method of the pre-oxidized fiber of the present invention can accurately reflect the degree of oxidation of the pre-oxidized fiber through a large amount of experimental measurement data, the result of the method is relatively accurate, the CV% value is small, and the influence of human fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com