System and method for detecting void mass energy of thick steel shell concrete

A technology for concrete and concrete structures, which is applied in the processing of detection response signals, the generation of ultrasonic/sonic/infrasonic waves, and the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of poor applicability and low detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

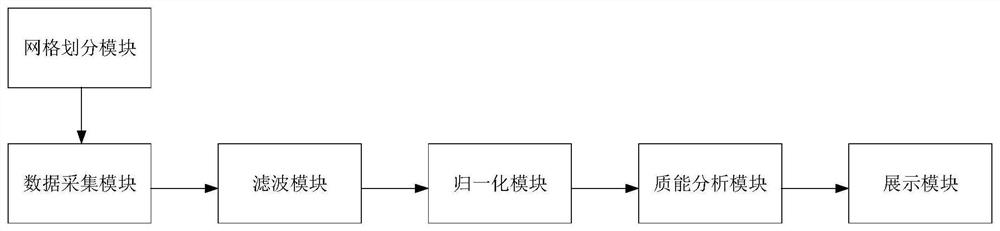

[0073] Such as figure 1 As shown, the present invention provides a hollow quality and energy detection system for thick steel shell concrete, including a grid division module, a data acquisition module, a filter module, a normalization module, a quality and energy analysis module and a display module; grid division The module is used to divide the thick steel shell concrete into grids to determine the detection area; the data acquisition module is used to use the percussion hammer to apply impact loads on the detection area to excite elastic vibration waves, and according to the excited elastic vibration waves, use The sensor obtains the free vibration wave of the steel plate surface in the detection area; the filter module is used to decompose and filter the free vibration wave of the steel plate surface to eliminate noise; the normalization module is used to normalize the automatic vibration wave after noise elimination processing to obtain the normalized free vibration wave...

Embodiment 2

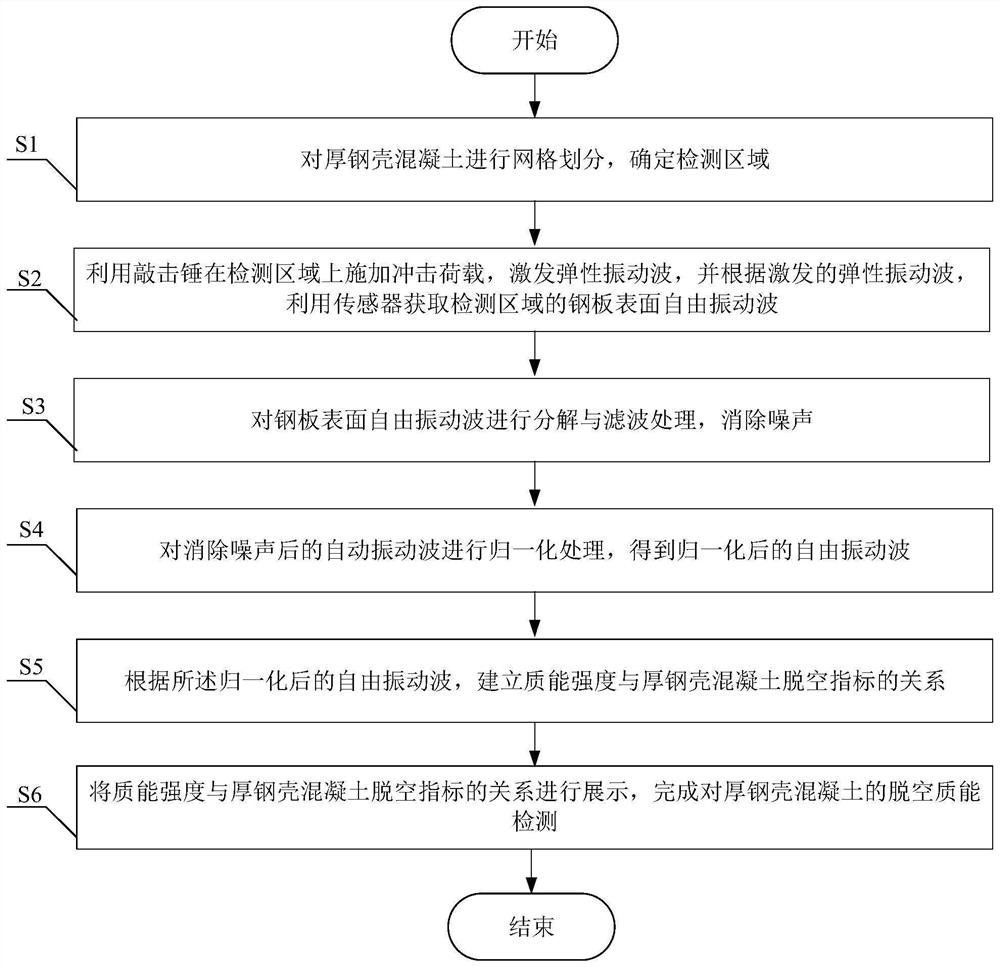

[0077] Such as figure 2 As shown, the present invention provides a method for detecting void mass and energy of thick steel shell concrete, and its implementation method is as follows:

[0078] S1. Mesh division of thick steel shell concrete to determine the detection area;

[0079] In this embodiment, since the void area and void height are detected by different detection devices, the coverage areas of the two detection devices are different, and the divided grids provide standards for the detection areas of the two devices, realizing the full detection of the detection areas. Covering; after the steel shell concrete is divided into grids, statistics and analysis can be carried out according to the void situation in different grids, providing detailed data support for improving the quality of steel shell concrete pouring.

[0080] S2. Using a percussion hammer to apply an impact load on the detection area to excite an elastic vibration wave, and according to the excited ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com