A kind of reactive ink for digital printing and preparation method thereof

A technology of active ink and digital printing, which is applied in dyeing, textiles and papermaking, etc., can solve environmental pollution and other problems, and achieve the effects of avoiding environmental pollution, improving stability and reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

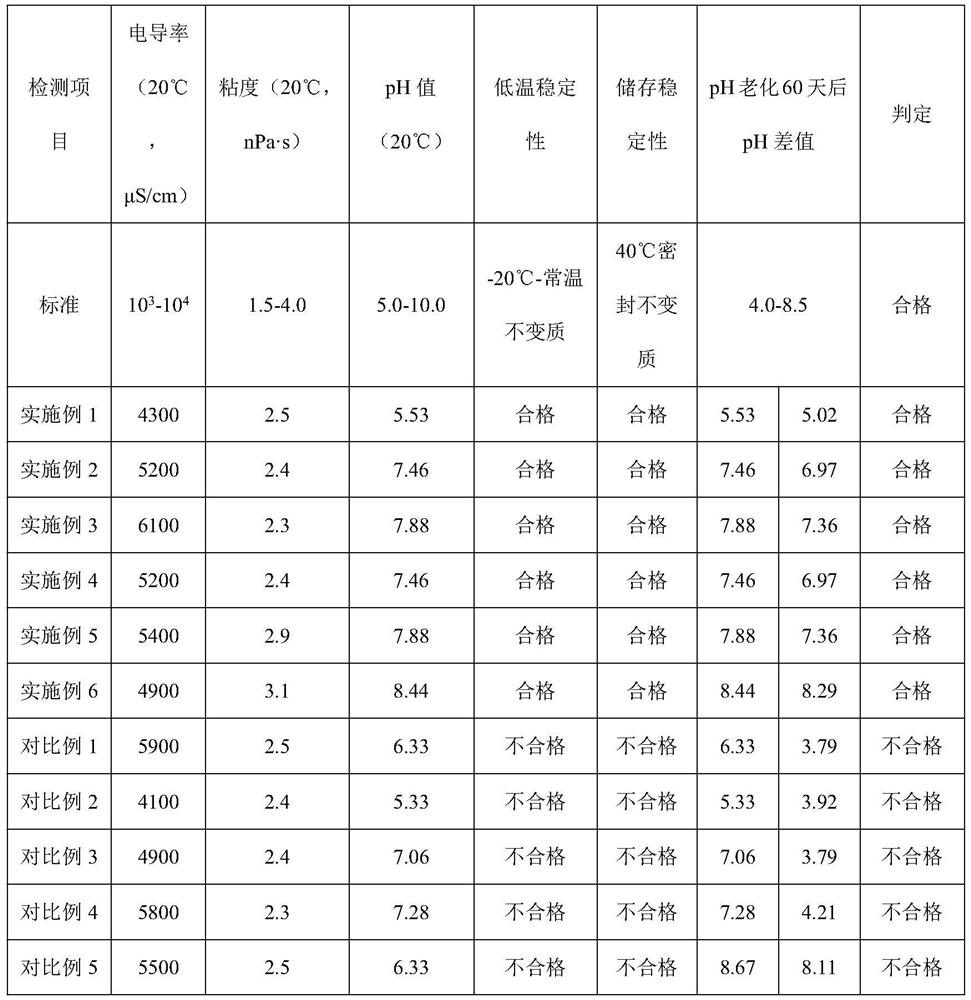

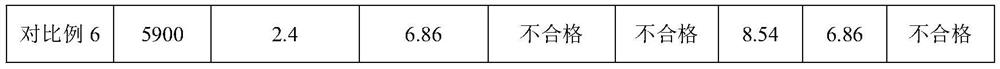

[0048]Digital printing reactive dye inkjet ink, which comprises the following components by weight percentage: reactive black 512%, triethylene glycol 10%, alkoxylated alcohol 0.5%, trimethylolpropenoate 0.8%, EDTA two Sodium 1.8%, thiazole fungicide 0.2%, caprolactam 7%, triethylamine 1%, NP-102%, and the balance is deionized water. The above components are mixed in proportion, stirred for 2 hours and mixed evenly, aged at 60° C. for 24 hours, and filtered with a 0.5-micron medium-speed filter paper to obtain a digital printing active ink.

Embodiment 2

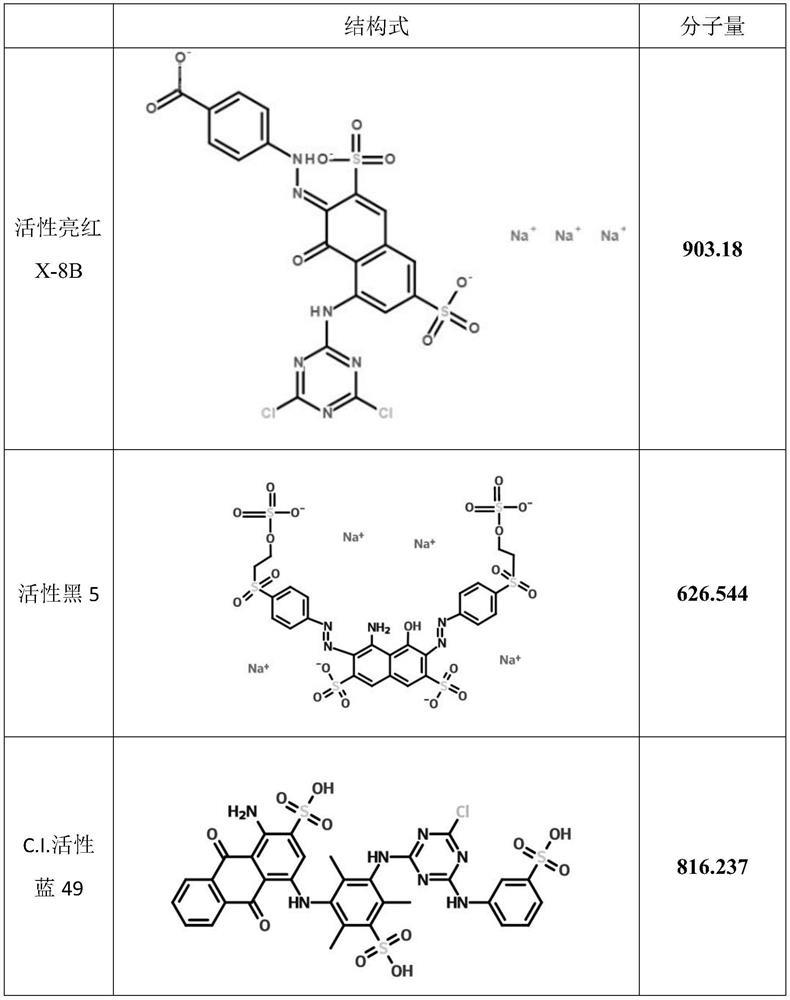

[0050] Digital printing reactive dye inkjet ink, which includes the following components by weight: reactive bright red X-BB 15%, triethylene glycol 12%, alkoxylated alcohol 1%, trimethylolpropenoate 0.8% , EDTA disodium 1.6%, thiazole fungicides 0.2%, caprolactam 10%, triethylamine 1%, NP-10 1.5%, the rest are deionized water. After stirring the above components according to the corresponding contents for 2 hours and mixing them uniformly, they were aged at 60° C. for 24 hours, and filtered with a 0.5-micron medium-speed filter paper to obtain a digital printing active ink.

Embodiment 3

[0052] Reactive dye inkjet ink for digital printing, which includes the following components by weight percentage: C.L. reactive blue 4917%, 1,2 propylene glycol 11%, alkoxylated alcohol 1%, trimethylolpropenoate 1.0%, EDTA Disodium 1.4%, thiazole fungicide 0.4%, caprolactam 8%, triethylamine 2%, NP-102%, and the rest are deionized water. After stirring the above components according to the corresponding contents for 2 hours and mixing them uniformly, they were aged at 60° C. for 24 hours, and filtered with a 0.5-micron medium-speed filter paper to obtain a digital printing active ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com