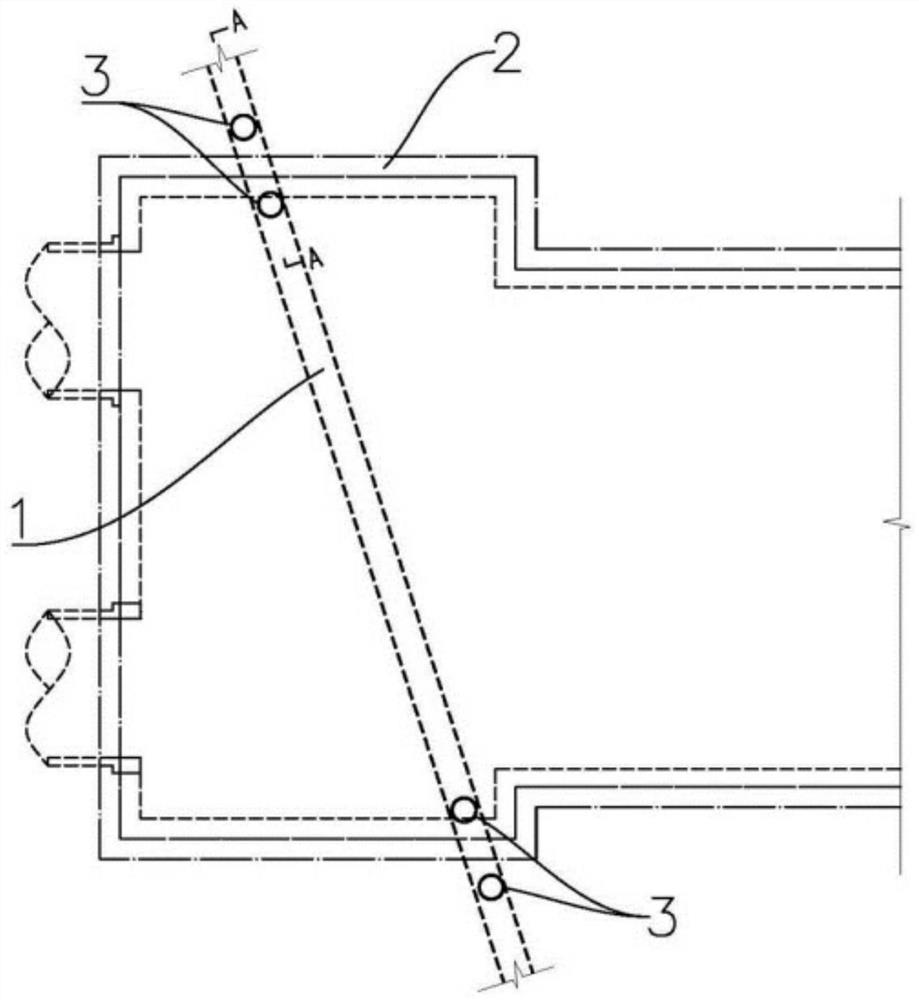

Diaphragm wall construction method across deep buried large municipal pipelines

A construction method and municipal technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as dependence, time-consuming and laborious, and achieve the effects of uniform compaction operation, convenient and controllable operation, and fast filtering speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

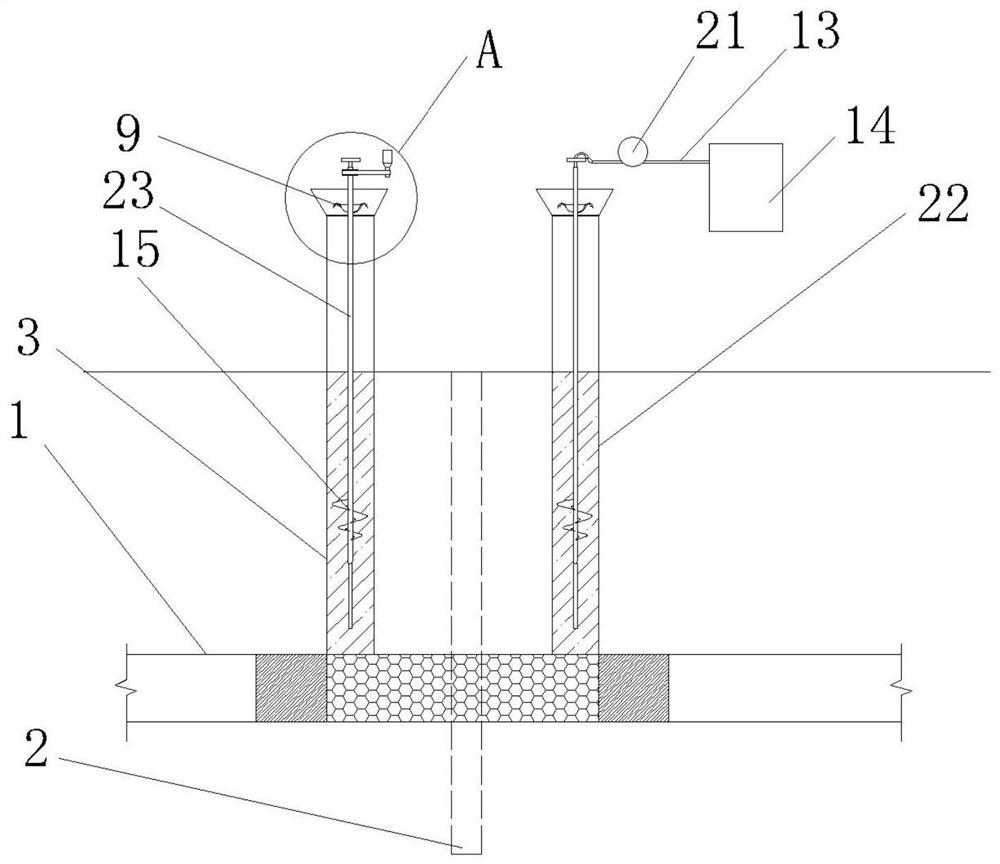

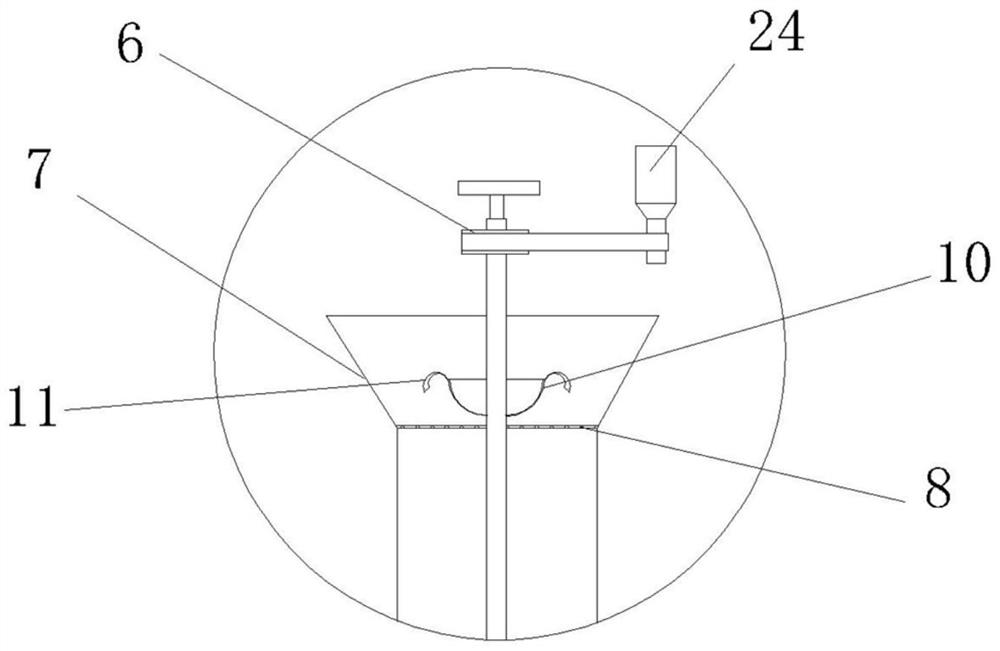

[0047] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the present invention also discloses that the steel casing assembly includes a cylinder body 22, a stirring and extruding sleeve 23 inserted into the cylinder body at the bottom end, and a driving motor 24, and the stirring and extruding sleeve includes an inner tube 4 And the outer tube 5, the top of the outer tube is equipped with a runner 6, and the runner 6 is connected to the output shaft of the drive motor through a belt drive. The top of the cylinder body is provided with a loading hopper 7 connected to the outer pipe, the bottom of the loading hopper is provided with a filter screen 8, and the upper part of the outer tube above the filter screen is provided with an extruding part 9, and the extruding part includes a bowl A body 10, the top of the bowl is provided with a connecting piece 11 extending outward on the outer arc surface, and the end of the connecting piece i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com