Humidifying and dampening method for tobacco processing

A tobacco and moisture regain machine technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as insufficient moisture regain, nozzle blockage, unfavorable activities, etc., and achieve fast moisture regain, increase loss, and increase water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

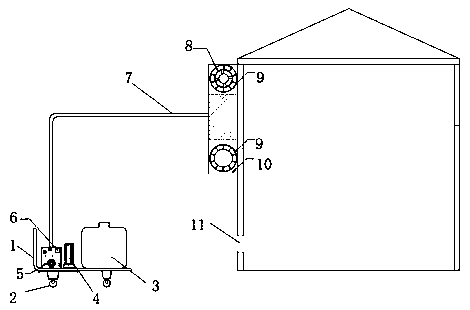

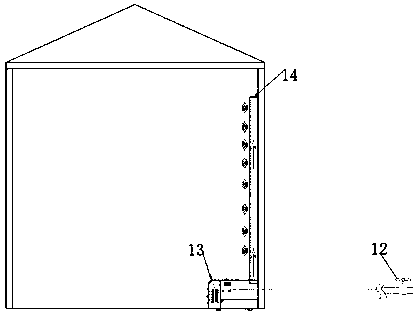

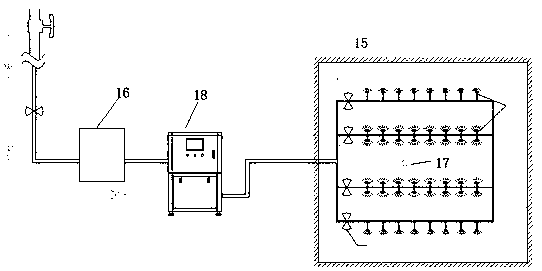

[0019] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

[0020] The specific embodiment of the tobacco processing humidification and moisture regain method involved in the present invention is mainly based on the different environmental humidity requirements of each process in the tobacco processing process.

[0021] In the process of production and purchase, it is more accurate to judge the moisture content of tobacco leaves is the halogen moisture detector. In practice, the method often used is to use the sensory test method to conduct on-site moisture inspection. According to the different natural climates, in the second and third quarters, the percentage of primary flue-cured tobacco should be controlled at 16% to 17%; in the first and fourth quarters, 16% to 18% is appro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com