Device and method for densification of aluminum matrix composites reinforced with high volume fraction sic nanowires based on three-dimensional constrained deformation

An aluminum-based composite material, high volume fraction technology, applied in metal processing and other directions, can solve problems such as easy cracking, and achieve the effects of avoiding cracking, easy operation, and simple restraint body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

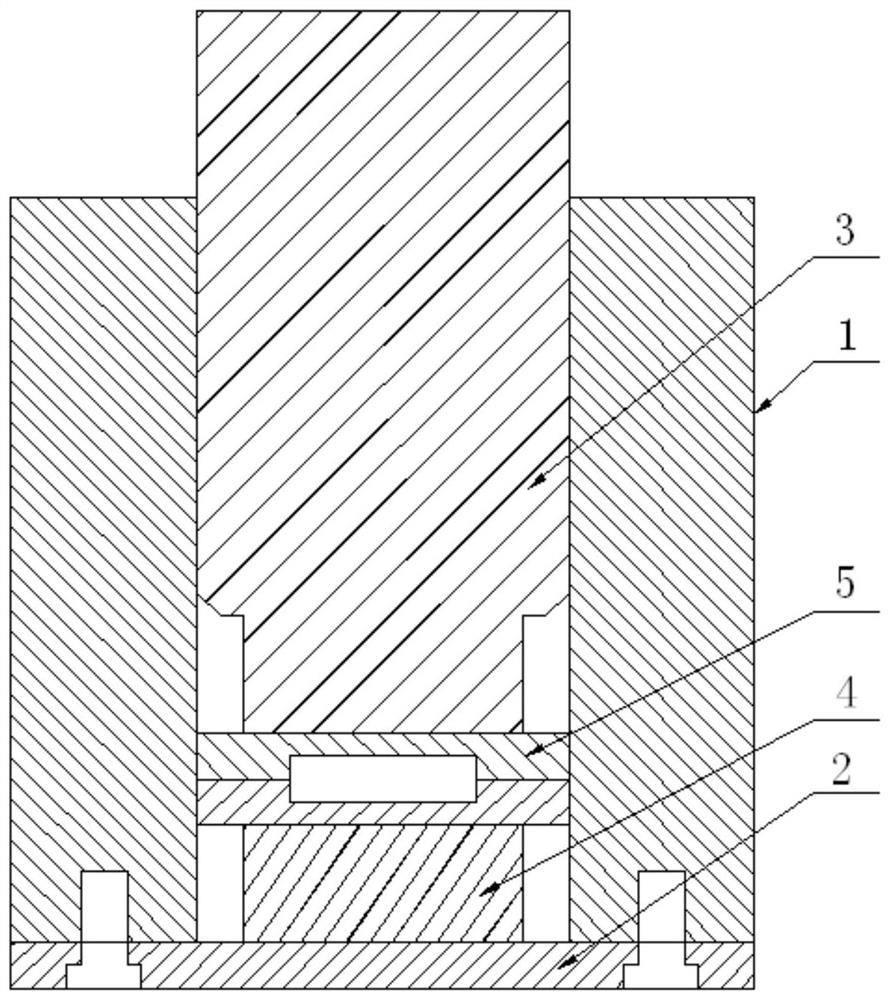

[0027] Specific Embodiment 1: In this embodiment, a high volume fraction SiC nanowire-reinforced aluminum matrix composite material densification device based on three-way constrained deformation is composed of a mold 1, a mold bottom plate 2, an upper indenter 3, a lower indenter 4, and a restraining body;

[0028] The mold 1 is a cylinder, and the mold 1 is arranged on the upper surface of the mold bottom plate 2, and the upper pressing head 3, the lower pressing head 4 and the constraint body are stacked inside the mold 1 from top to bottom; the upper pressing head 3 and the lower pressing head 4 is a cylinder, the lower end surface of the upper pressing head 3 is provided with a first cylindrical boss, and the upper end surface of the lower pressing head 4 is provided with a second boss having the same shape and size as the first boss;

[0029] The constraining body is a cylinder, and the outer peripheral surface of the constraining body is in clearance fit with the inner p...

specific Embodiment approach 2

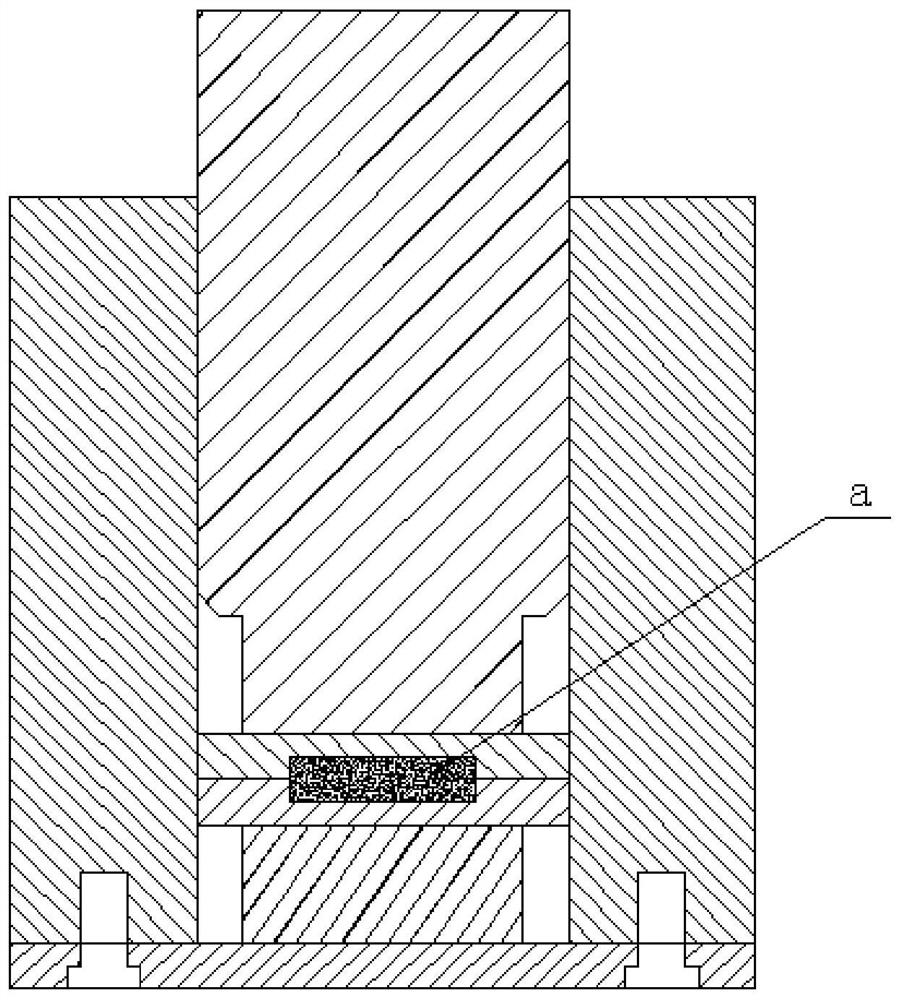

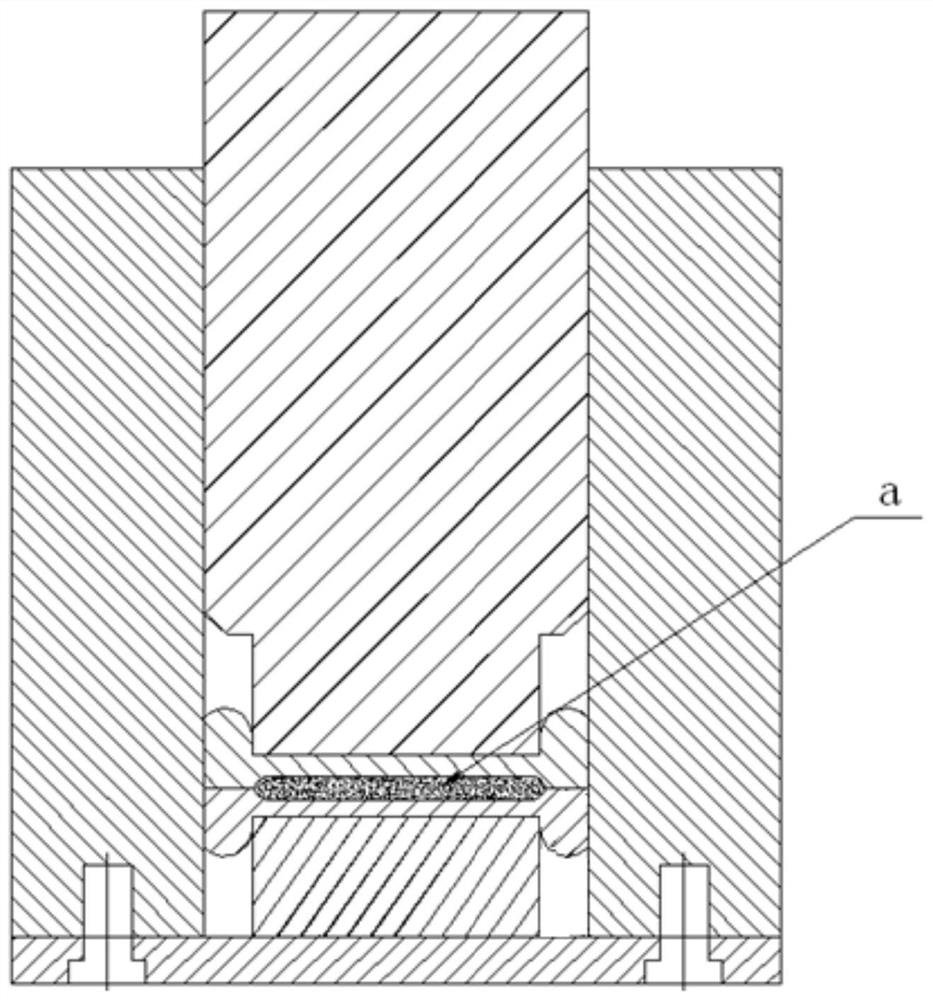

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that: the distance between the bottom of the circular blind hole in the semi-constraining body 5 and the end surface of the semi-constraining body 5 is 2-5 mm. Other steps and parameters are the same as those in the first embodiment. The constraining body is made of two semi-constraining bodies 5 that are symmetrical up and down. When the aluminum-based composite material is filled into the cavity of the constraining body, it can be kept in close contact with the constraining body. The distance between the bottom of the circular blind hole in the semi-constraining body 5 The distance between the end faces of adjacent constraining bodies is 2-5mm, so the distance between the end face of the aluminum-based composite material and the upper or lower indenter is 2-5mm, which can ensure that the aluminum-based composite material is in a relatively uniform deformation area, so that The deformation of different parts of...

specific Embodiment approach 3

[0035]Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the mold 1 is connected to the mold bottom plate 2 by bolts, the mold bottom plate 2 is provided with a through hole, and the inner lower end surface of the side wall of the mold 1 is provided with threads Hole, the bolt passes through the through hole of the mold bottom plate 2 and is screwed in the threaded hole of the side wall of the mold 1. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com