Pin press-fitting machine for assembling automobile air conditioner compressor base and application method of pin press-fitting machine

A technology of automotive air conditioners and compressors, which is applied to vehicle parts, transportation and packaging, metal processing, etc., and can solve problems such as cumbersome movements, inability to guarantee verticality, and increased scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

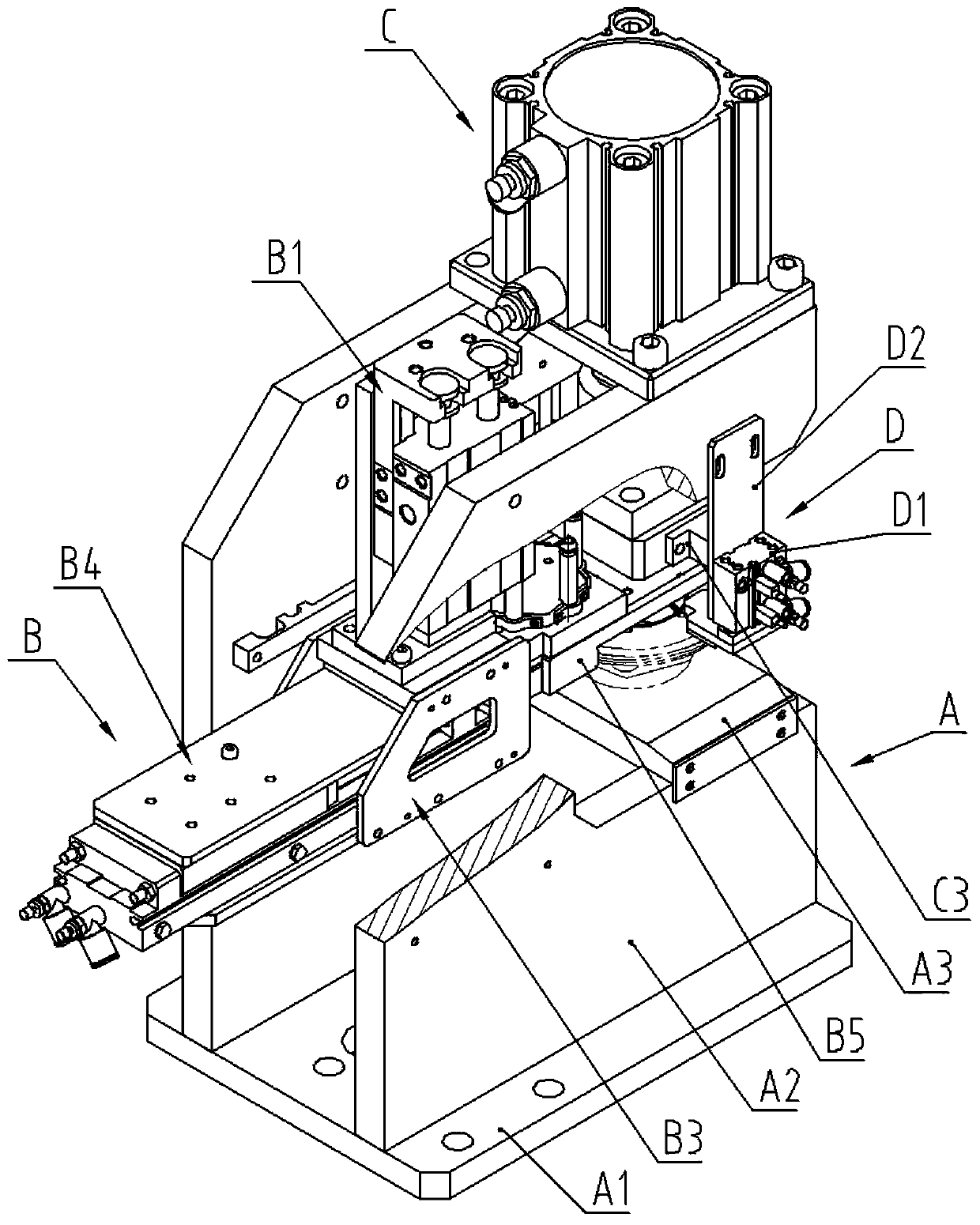

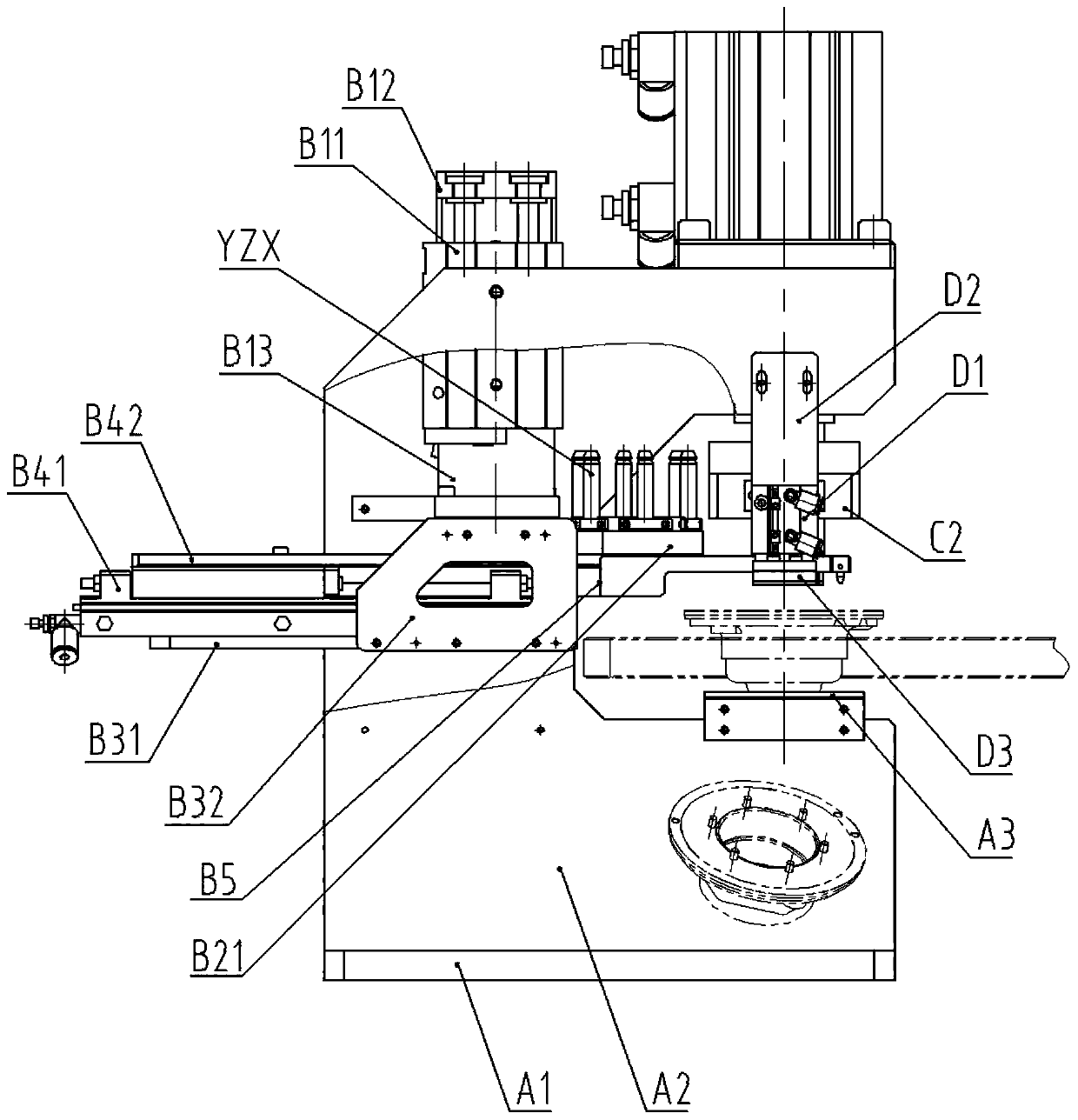

[0039] Such as figure 1 , figure 2 As shown, the pin pressing machine for assembly of the automobile air-conditioning compressor base disclosed in this embodiment includes a support frame A, a pin feeding device B, a pin pre-pressing mechanism C, and a base pressing mechanism D.

[0040] The support frame A includes a base plate A1, a cylinder support plate A2, and a base plate A3. Both the base plate A1 and the cylinder support plate A2 are rectangular plates. A U-shaped notch is opened in the middle of one side, and the base backing plate A3 is fixed on the bottom of the U-shaped notch between the two cylinder support plates A2.

[0041] Such as figure 1 As shown, the pin feeding device B includes a vertical lifting mechanism B1, a pin distribution assembly B2, a hanger B3, a horizontal pushing mechanism B4 and a pre-pressing pin assembly plate B5.

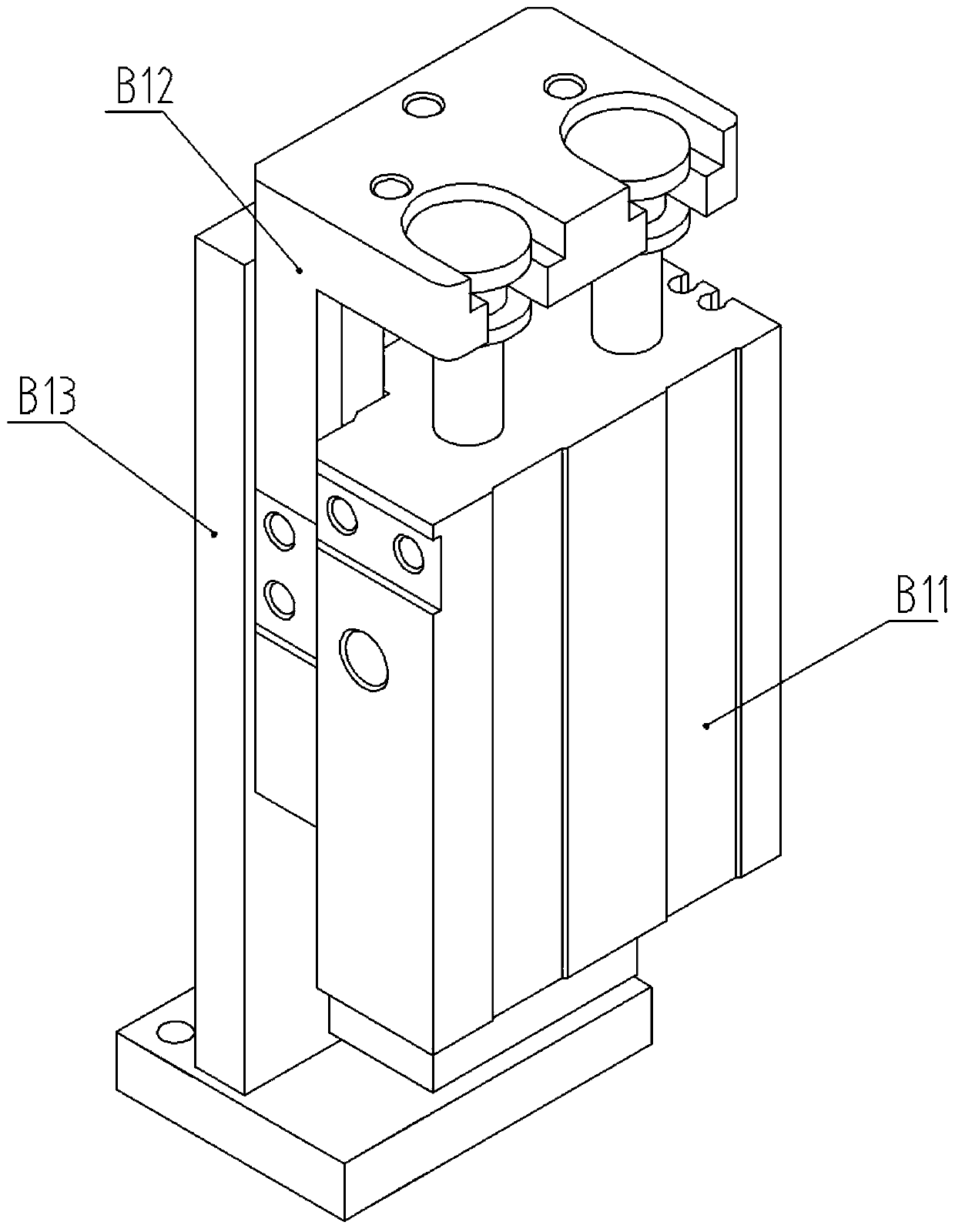

[0042] Such as image 3 As shown, the vertical lifting mechanism B1 includes a lifting cylinder B11, a carriage B12 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com