A method for modeling edge removal function and edge effect suppression in magnetorheological polishing

A magnetorheological polishing and edge effect technology, which is applied in grinding/polishing equipment, manufacturing tools, grinding automatic control devices, etc., can solve problems such as low efficiency, low processing accuracy, and poor edge surface shape control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

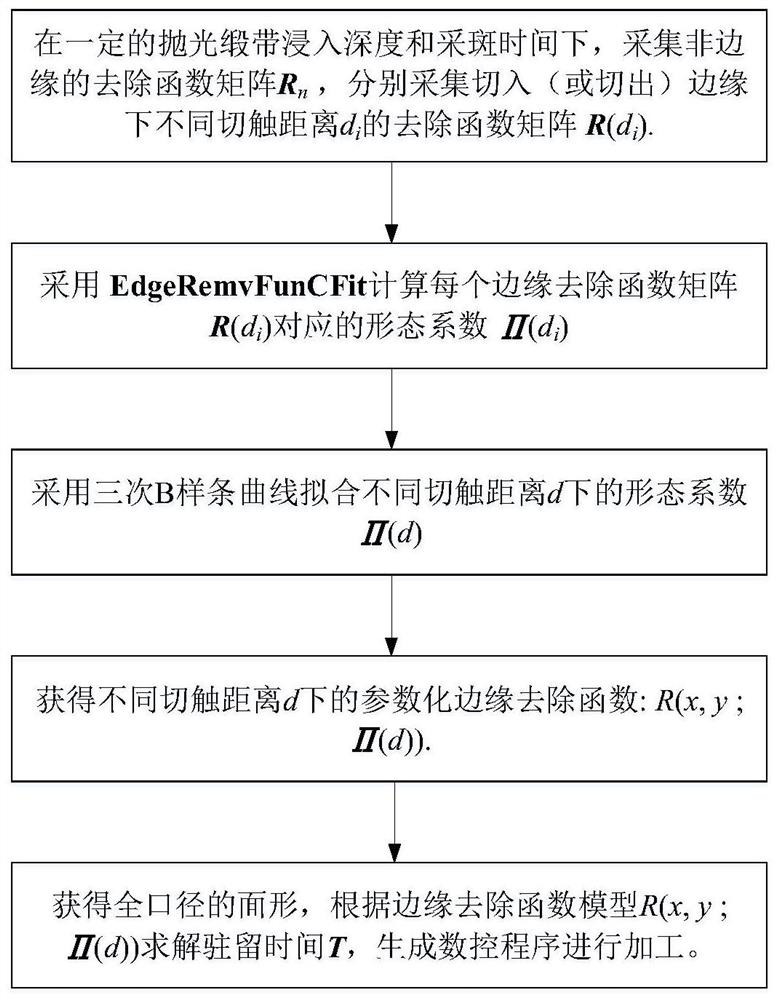

[0076] The present invention relates to a magnetorheological polishing edge removal function modeling and edge effect suppression method, the method comprising the following steps:

[0077] S1. Under the given magnetorheological polishing satin immersion depth and spot sampling time, collect non-edge polishing spots and polishing spots with different contact distances in the two cases of cutting into the edge and cutting out the edge, so as to obtain non-edge The length and width of the polishing spot;

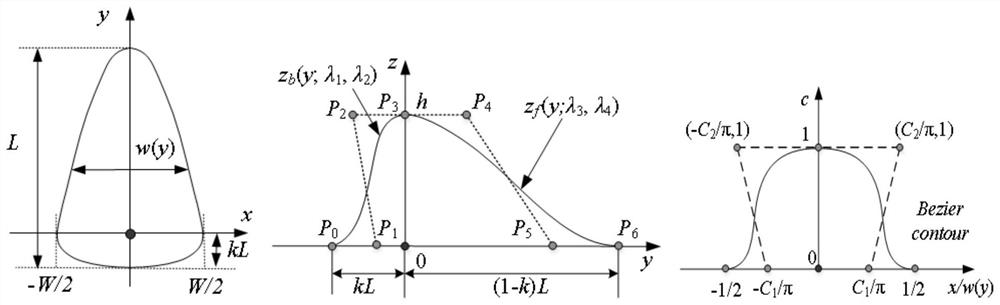

[0078] S2. According to the length and width of the non-edge polishing spot obtained in step S1, a parameterized model of magnetorheological polishing removal function based on Bezier splines is established;

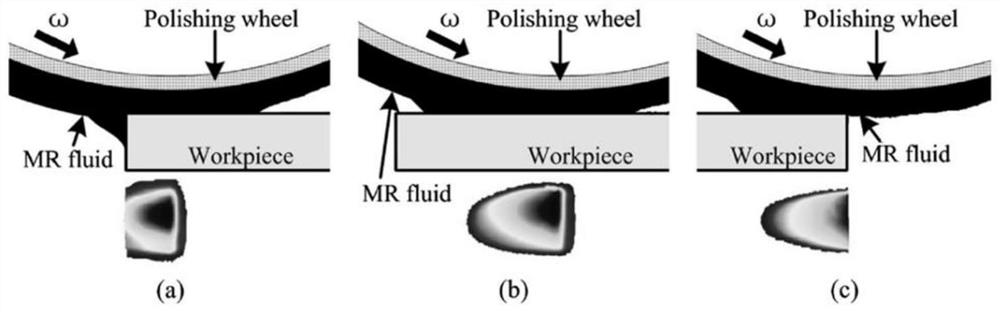

[0079] S3. Establishing an edge removal function reconstruction method for different contact states, and performing geometric modeling; wherein, the contact state includes two cases of cut-in and cut-out;

[0080] S4. Formulate a dwell time solution strategy based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com