High-strength and low-VOC automotive interior polypropylene composite material and preparation method thereof

A composite material, high-strength technology, used in the field of automotive interior parts, can solve the problems of insufficient strength of polypropylene composite materials, volatile VOC gas, harm to the human body, etc., and achieve the effect of excellent comprehensive performance, high strength and low VOC.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

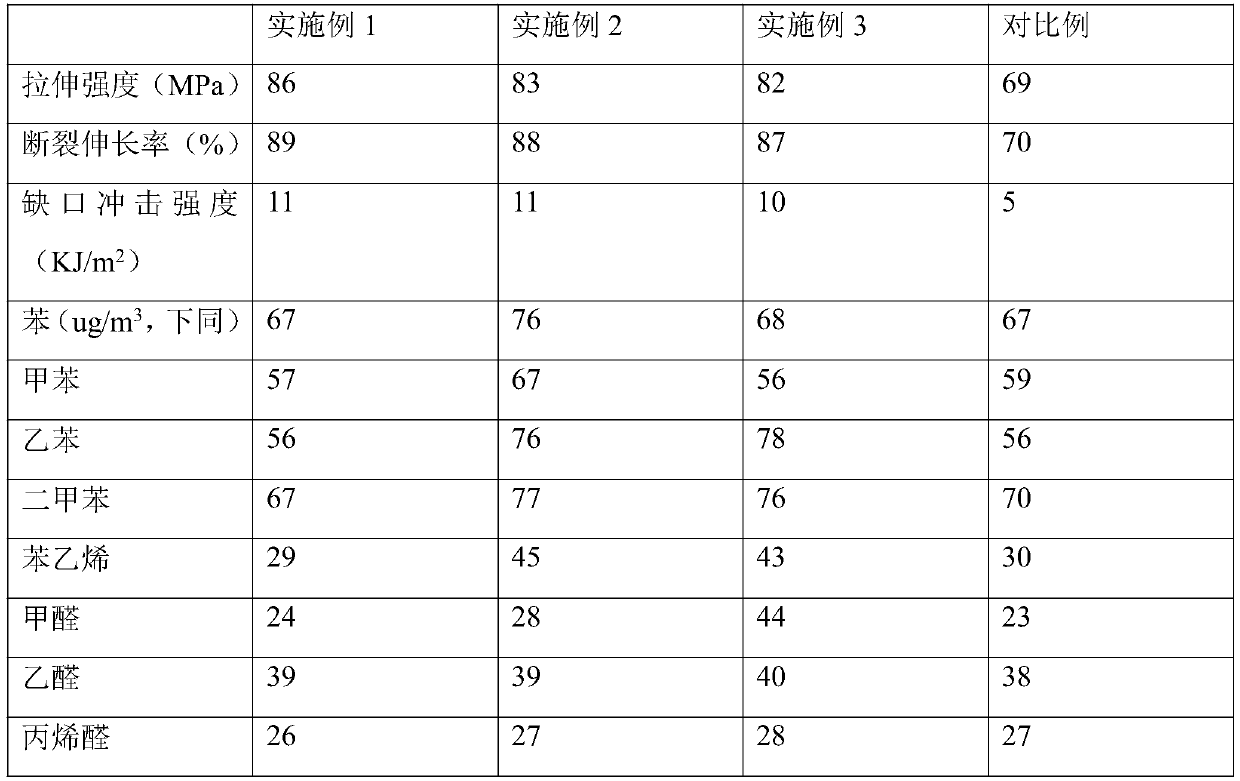

Embodiment 1

[0022] A high-strength and low-VOC automotive interior polypropylene composite material, in terms of mass components, comprising the following components: polypropylene resin: 100 parts; toughening agent: 15 parts; antioxidant: 1 part; diatoms Soil: 10 parts; light stabilizer 1 part; flame retardant 10 parts; reinforcing agent 20 parts; inorganic filler 15 parts.

[0023] The preparation method of this polypropylene composite material is as follows:

[0024] (1) Add polypropylene resin, diatomaceous earth, reinforcing agent, and inorganic filler into the high-speed mixer according to the mass ratio under the condition of 25-30°C for 3-5 minutes, then let it stand for 3 hours, continue Add toughener, antioxidant, light stabilizer and flame retardant in sequence, and continue blending for 3-5 minutes;

[0025] (2) Put the mixture treated in step (1) into a twin-screw extruder for melting and kneading, and extrude and granulate under the condition of a vacuum degree of -0.03 to ...

Embodiment 2

[0027] A high-strength and low-VOC automotive interior polypropylene composite material, in terms of mass components, comprising the following components: polypropylene resin: 80 parts; toughening agent: 10 parts; antioxidant: 0.5 parts; diatoms Soil: 5 parts; 0.5 parts of light stabilizer; 5 parts of flame retardant; 15 parts of reinforcing agent; 10 parts of inorganic filler.

[0028] The preparation method of this polypropylene composite material is as follows:

[0029] (1) Add polypropylene resin, diatomaceous earth, reinforcing agent, and inorganic filler into the high-speed mixer according to the mass ratio under the condition of 25-30°C for 3-5 minutes, then let it stand for 3 hours, continue Add toughener, antioxidant, light stabilizer and flame retardant in sequence, and continue blending for 3-5 minutes;

[0030] (2) Put the mixture treated in step (1) into a twin-screw extruder for melting and kneading, and extrude and granulate under the condition of a vacuum degr...

Embodiment 3

[0032] A high-strength and low-VOC automotive interior polypropylene composite material, in terms of mass components, comprising the following components: polypropylene resin: 100 parts; toughening agent: 10 parts; antioxidant: 1 part; diatoms Soil: 5 parts; light stabilizer 1 part; flame retardant 5 parts; reinforcing agent 25 parts; inorganic filler 10 parts.

[0033] The preparation method of this polypropylene composite material is as follows:

[0034] (1) Add polypropylene resin, diatomaceous earth, reinforcing agent, and inorganic filler into the high-speed mixer according to the mass ratio under the condition of 25-30°C for 3-5 minutes, then let it stand for 3 hours, continue Add toughener, antioxidant, light stabilizer and flame retardant in sequence, and continue blending for 3-5 minutes;

[0035] (2) Put the mixture treated in step (1) into a twin-screw extruder for melting and kneading, and extrude and granulate under the condition of a vacuum degree of -0.03 to -0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com