Normal pressure degasser

A degasser, atmospheric pressure technology, used in liquid degassing, chemical instruments and methods, wellbore/well components, etc. Simple structure, high degassing efficiency, and the effect of improving degassing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

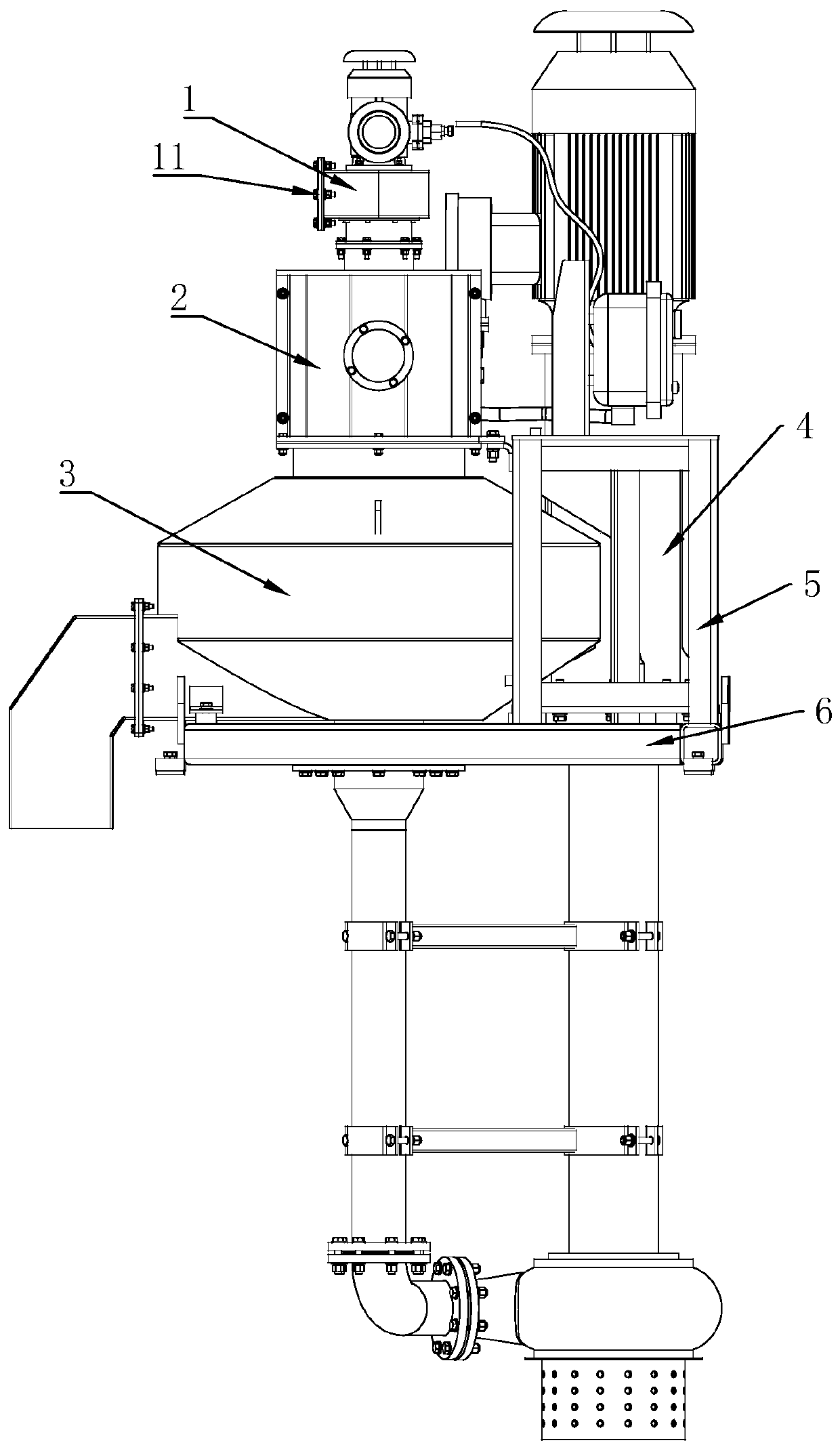

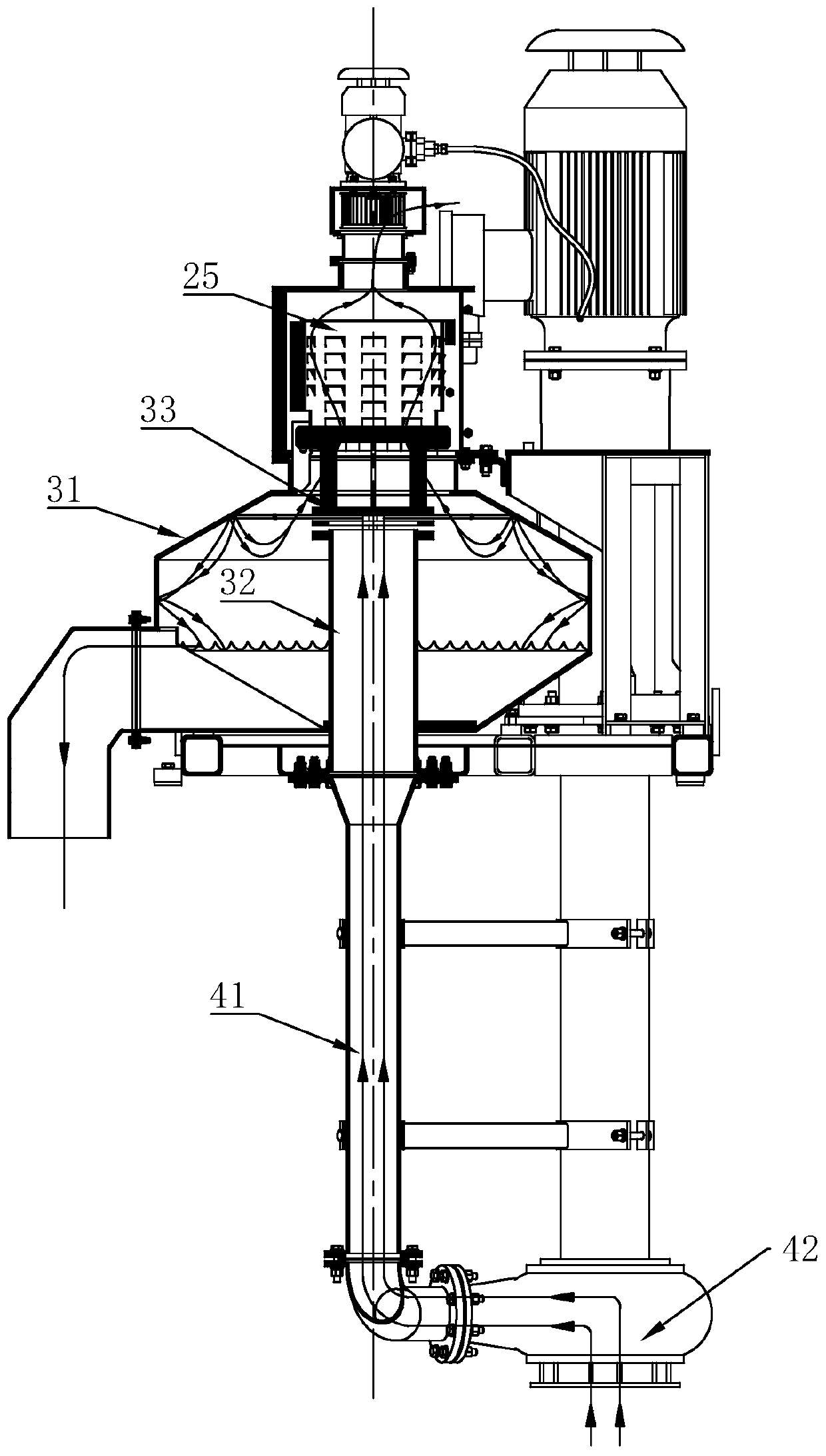

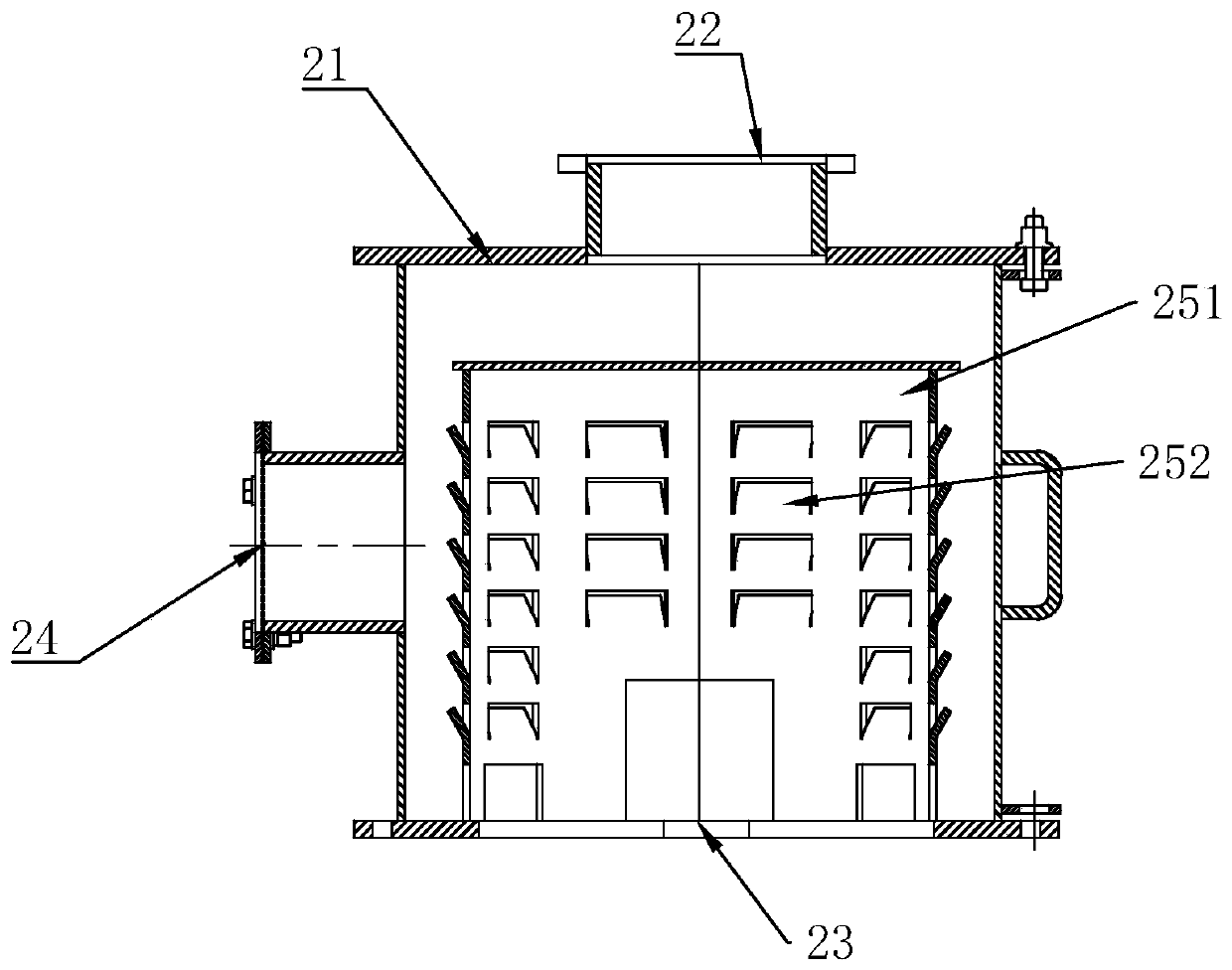

[0028] Such as figure 1 As shown, the present invention provides a kind of normal pressure degasser, comprises blower 1, ventilation device 2, injection device 3 and slurry pump 4, and injection device 3 comprises tank body 31, and tank body 31 is installed on the support base 6, and tank body A liquid inlet pipe 32 is vertically pierced in the body 31, and the lower end of the liquid inlet pipe 32 is connected with the standpipe 41 of the slurry pump 4, and the slurry pump 4 is installed on the support base 5, and the support base 5 is fixed on the support base 6 , the upper end of the liquid inlet pipe 32 is provided with an impact assembly 33, the upper ends of the impact assembly 33 are installed on the support frame 34 and move vertically relative to it, so as to adjust the distance between the impact assembly 33 and the upper end surface of the liquid inlet pipe 32, The support frame 34 is fixed on the inner periphery of the upper end of the tank body 31, the side end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com