A system and method for multi-stage utilization of air compressor waste heat

An air compressor, first-class technology, applied in heat pumps, refrigerators, mechanical equipment, etc., can solve the problems of not considering air temperature, waste heat cannot be effectively utilized, and system heat loss is large, so as to avoid heat loss and improve waste heat. Utilize efficiency and reduce the effect of intermediate heat exchange equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

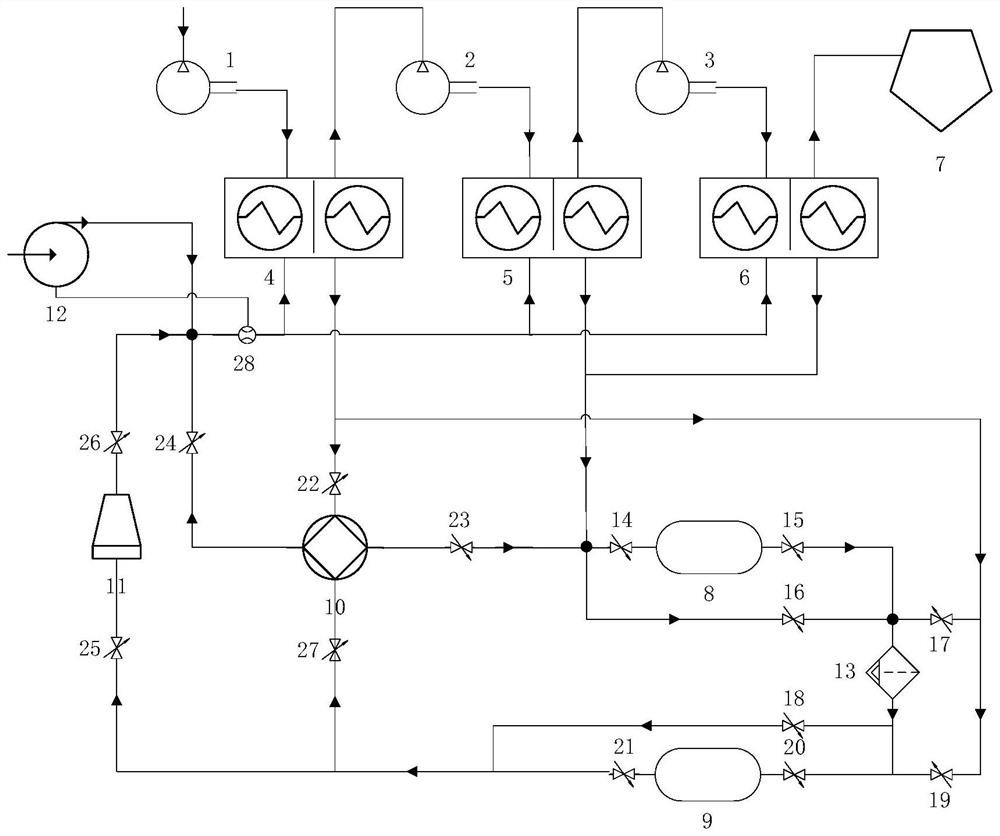

[0031] The waste heat recovery method of the air compressor waste heat multi-stage utilization system, specifically:

[0032] Summer cooling mode:

[0033] In the summer cooling operation mode, the switch valves 14, 15, 18, 22, 23, 24, 25, 26 are in the open state, and the switch valves 16, 17, 19, 20, 21 are in the closed state. The switch regulating valve 27 is in an open state.

[0034] 150,000 Nm 3 / h The air at normal temperature and pressure reaches 95°C after being compressed by the first stage of the air compressor, and enters the first stage heat exchanger 4 to exchange heat with the cooling water at 35°C. After the heat exchange, the compressed air temperature is 40°C and enters the air compressor Two-stage compression, three-stage compression of the air compressor, the temperature of the second-stage compressed air and the third-stage compressed air can reach 120°C, after compression, it enters the second-stage heat exchanger 5 and the third-stage heat exchanger 6...

Embodiment 2

[0038] The waste heat recovery method of the air compressor waste heat multi-stage utilization system, specifically:

[0039] Winter heating mode:

[0040] In the winter heating operation mode, the on-off valves 16, 20, 21, 23, 24, 25, and 26 are in the open state, the on-off valves 14, 15, 17, and 18 are in the closed state, and the on-off valves 19 and 22 are in the adjustable state. The regulating valve 27 is in an open state.

[0041] 150,000 Nm 3 / h Normal temperature and normal pressure air passes through the first stage of the air compressor, and the temperature reaches 80°C, and enters the first stage heat exchanger 4 to exchange heat with 35°C cooling water. After the heat exchange, the compressed air temperature is 40°C and enters the air compressor Two-stage compression, three-stage compression of the air compressor, the temperature of the second-stage compressed air and the third-stage compressed air can reach 105°C, after being compressed, it enters the second-s...

Embodiment 3

[0044] The waste heat recovery method of the air compressor waste heat multi-stage utilization system, specifically:

[0045] Non-cooling and non-heating mode in spring and autumn:

[0046] In the spring and autumn non-cooling and non-heating operation mode, the on-off valves 16, 17, 18, 25, and 26 are in the open state, and the on-off valves 14, 15, 19, 20, 21, 22, 23, 24 and the on-off regulating valve 27 are in the closed state state.

[0047] 150,000 Nm 3 / h Normal temperature and normal pressure air passes through the first stage of the air compressor, and the temperature reaches 85°C, and enters the first stage heat exchanger 4 to exchange heat with 35°C cooling water. After the heat exchange, the compressed air temperature is 40°C and enters the air compressor Two-stage compression, three-stage compression of the air compressor, the temperature of the second-stage compressed air and the third-stage compressed air can reach 115°C, after compression, it enters the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com