Device and method for determining iron in water sample by sequential injection-fluorescence method

A technology of sequential injection and fluorescence method, which is applied in the field of analytical chemical detection, can solve problems affecting climate change, etc., and achieve the effects of easy automatic control, less human intervention, and simple and reliable system hardware

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

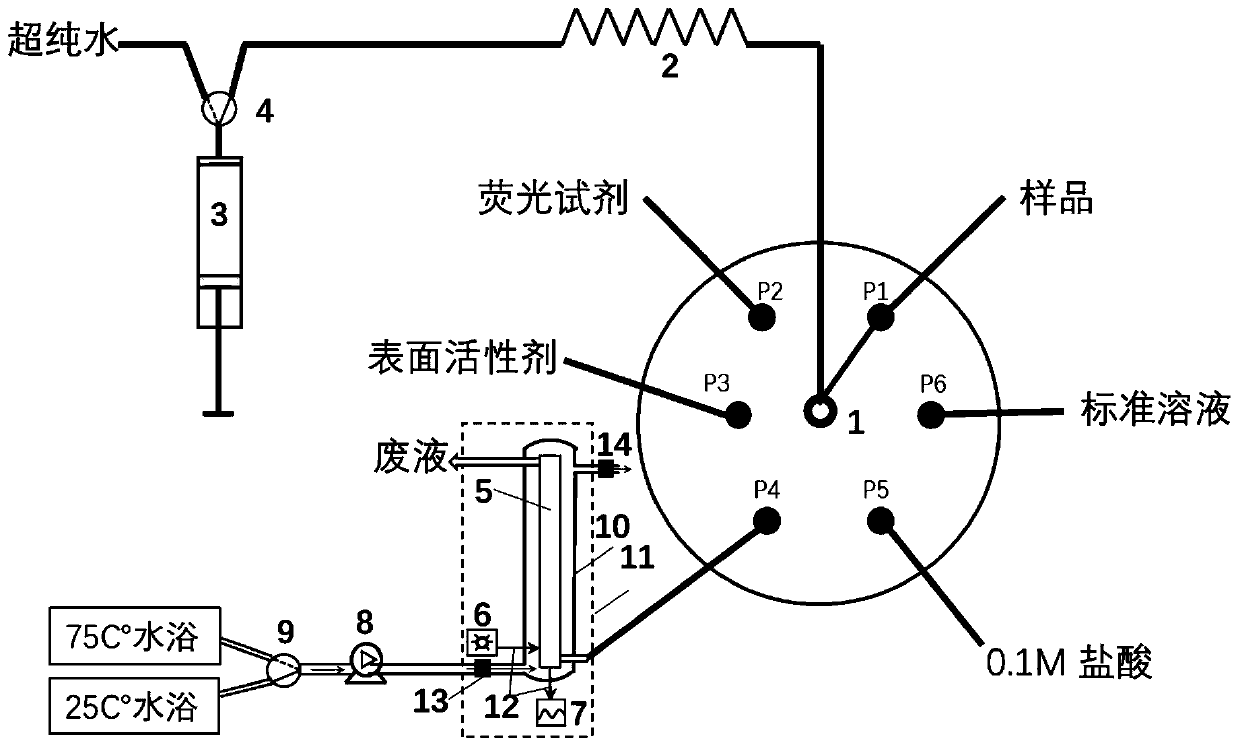

[0026] First embodiment: Determination of iron in water samples preserved by acidification

[0027] The main measurement steps are as follows:

[0028] 1. The six-position selector valve (1) is placed at the P1 port, and a 400 μl sample is extracted by the syringe pump (3);

[0029] 2. The six-position selector valve (1) is placed at the P2 port, and 200 μl of fluorescent reagent is extracted by the syringe pump (3);

[0030] 3. The six-position selector valve (1) is placed at the P3 port, and 200 μl of surfactant is extracted by the syringe pump (3);

[0031] 4. Place the six-position selector valve (1) at the P4 port, reversely push the syringe pump (3), and inject the mixed solution into the detection pool;

[0032] 5. Connect the second two-position three-way valve (9) to a 70°C water bath, turn on the water pump (8), keep it for 15 minutes, and then turn off the water pump (8);

[0033] 6. Connect the second two-position three-way valve (9) to a 25°C water bath, turn o...

no. 2 example

[0036] Second embodiment: Determination of iron in raw water sample (water sample not acidified)

[0037] The main measurement steps are as follows:

[0038] 1. The six-position selector valve (1) is placed at the P1 port, and a 360 μl sample is extracted by the syringe pump (3);

[0039] 2. The six-position selector valve (1) is placed at the P5 port, and 40 μl of 0.1M hydrochloric acid is extracted by the syringe pump (3);

[0040] 3. The six-position selection valve (1) is placed at the P2 port, and 200 μl of fluorescent reagent is extracted by the syringe pump (3);

[0041] 4. The six-position selector valve (1) is placed at the P3 port, and 200 μl of surfactant is extracted by the syringe pump (3);

[0042] 5. Place the six-position selector valve (1) at the P4 port, reversely push the syringe pump (3), and inject the mixed solution into the detection pool;

[0043] 6. Connect the second two-position three-way valve (9) to a 70°C water bath, turn on the water pump (8),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com