Quasi-optical system for terahertz beam shaping

A beam shaping and optical system technology, applied in the field of quasi-optical systems, can solve the problems of poor lens matching, signal attenuation, low transmittance, etc., and achieve the effects of improving system resolution, controlling chromatic aberration, and reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

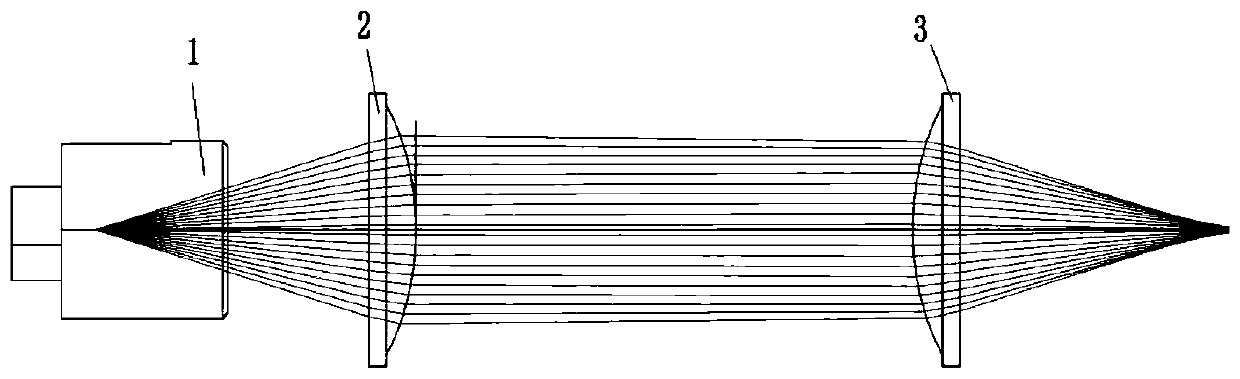

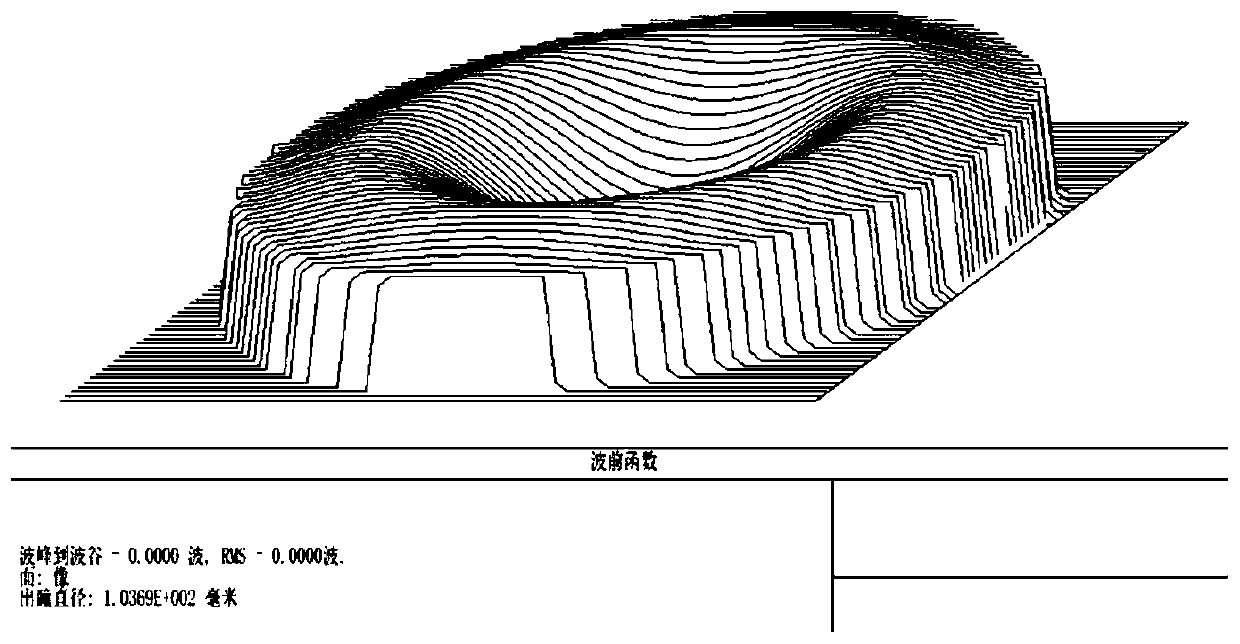

[0026] The quasi-optical system used for terahertz beam shaping involved in this embodiment includes a flat semiconductor crystal 1, a hyper-hemispherical silicon lens 2, and a collimator lens 3. One side of the hyper-hemispherical silicon lens 2 is a hyper-hemispherical surface, and the other side is a plane. The flat semiconductor The crystal 1 is glued to the plane side of the super hemispherical silicon lens 2, the collimator lens 3 is placed on the hyper hemispherical side of the hyper hemispherical silicon lens 2, and the optical axes of the flat semiconductor crystal 1, the hyper hemispherical silicon lens 2 and the collimation lens 3 coincide. The super hemispherical silicon lens 2 adopts high-resistance silicon material. The refractive index of semiconductor crystal material is generally 3.4-3.6, and the critical angle of total reflection in air is 16.13°-17.10°. High-resistance silicon with a refractive index similar to that of semiconductor crystal material is used A...

Embodiment 2

[0034] The quasi-optical system used for terahertz beam shaping involved in this embodiment includes a flat semiconductor crystal 1, a hyper-hemispherical silicon lens 2, a collimator lens 3, a focusing lens 4 and a focal plane 5, and one side of the hyper-hemispherical silicon lens 2 is a hyper-hemispheric One side is a plane, the flat semiconductor crystal 1 is glued to the plane side of the super hemispherical silicon lens 2, the collimating lens 3 is placed on the super hemispherical side of the hyper hemispherical silicon lens 2, and the focusing lens 4 is placed on the side of the collimating lens 3, The collimating lens 3 is close to the convex surface of the focusing lens 4, the focal plane 5 is placed at the focal point of the focusing lens 4, and the optical axes of the flat semiconductor crystal 1, the super hemispherical silicon lens 2, the collimating lens 3 and the focusing lens 4 coincide.

[0035] Further, the super hemispherical surface of the super hemispherical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com