Inner and outer circle grinding device for machining pipe

A technology for pipes and supporting mechanisms, applied in the field of pipe processing, can solve the problems of secondary scratches, multiple clamping, through-type scratches, etc., and achieve the effect of smooth grinding surface, guaranteeing grinding quality, and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

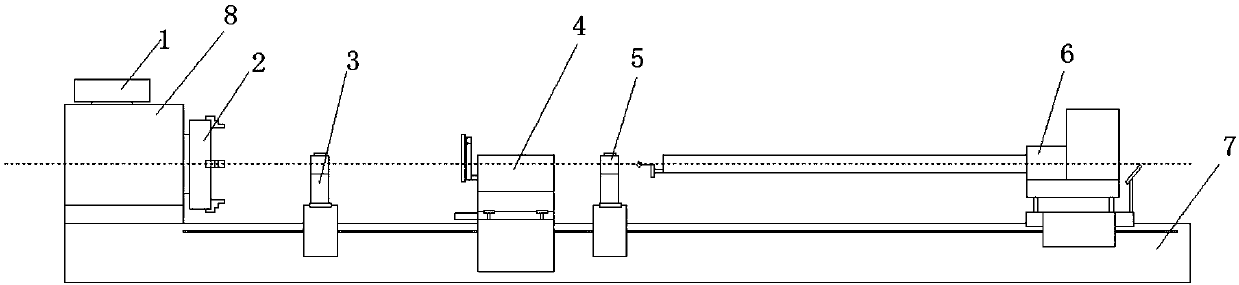

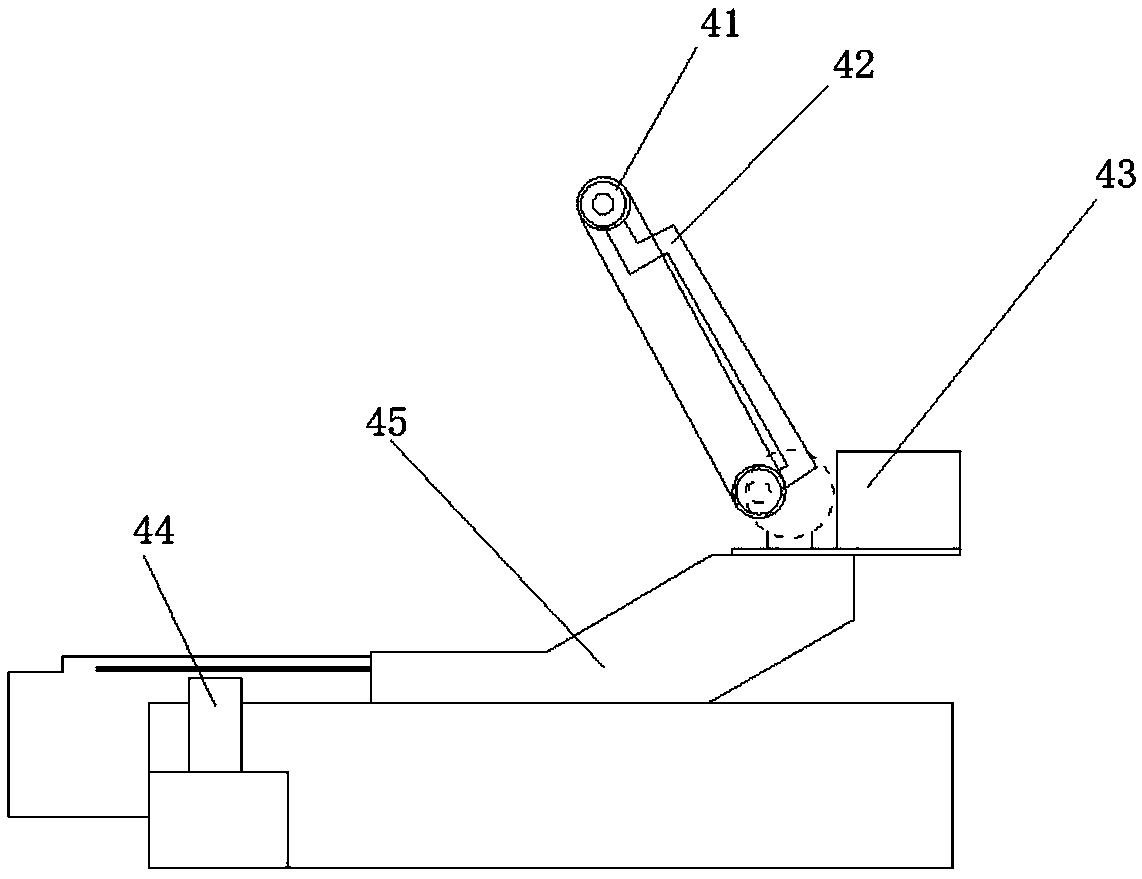

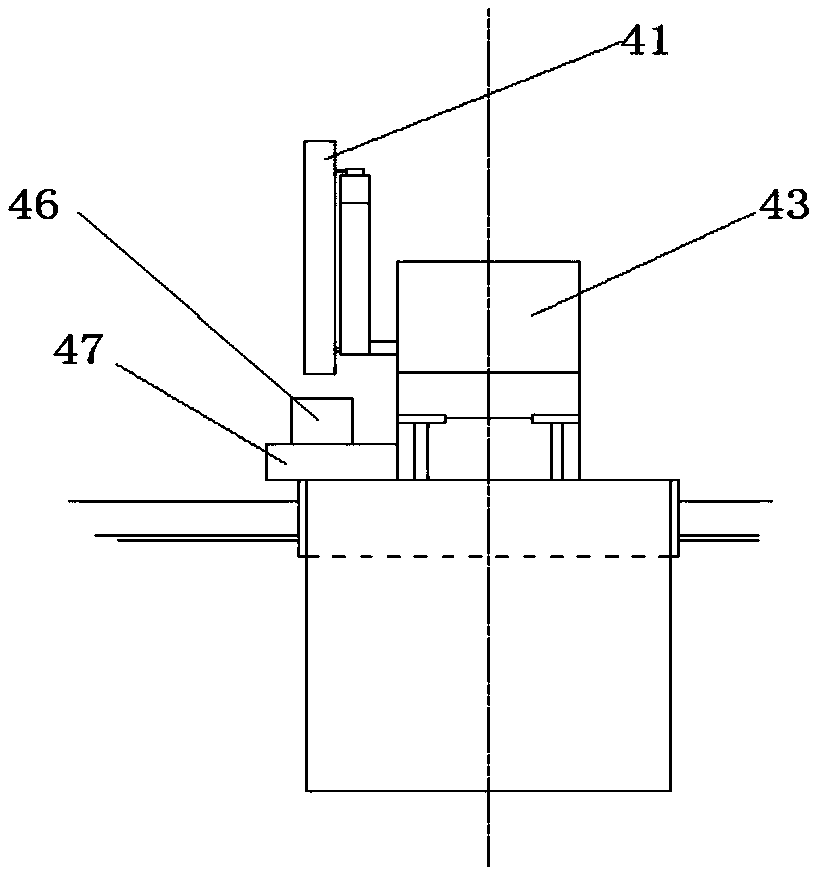

[0054] An inner and outer circle grinding device for processing pipe materials, the inner and outer circle grinding device includes a frame 7, and a main shaft mechanism, a first centering support mechanism 3, and an outer circle grinding mechanism arranged sequentially on the frame Mechanism 4, second centering support mechanism 5 and inner circle grinding mechanism 6;

[0055] The spindle mechanism includes a spindle motor 1, a spindle body 8 and a clamping mechanism 2; the clamping mechanism 2 is arranged on the end of the spindle body 8 close to the first centering support mechanism 3, and is used for clamping pipes; the spindle motor 1 Connected with the main shaft body 8, it is used to drive the rotation of the clamping mechanism 2 on the main shaft body 8, and then drive the rotation of the pipe;

[0056] The first centering support mechanism 3 and the second centering support mechanism 5 are used to support the pipe material and ensure that the center of the pipe mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com