Environment-friendly low-smoke flame-retardant HIPS material and preparation method thereof

A low-smoke, flame-retardant, and environmentally-friendly technology, applied in the field of environmentally friendly low-smoke, flame-retardant HIPS materials and their preparation, can solve problems such as hypoxia and suffocation, casualties, property, and losses, and achieve good low-smoke flame-retardant effects and flame-retardant effects Good, less smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

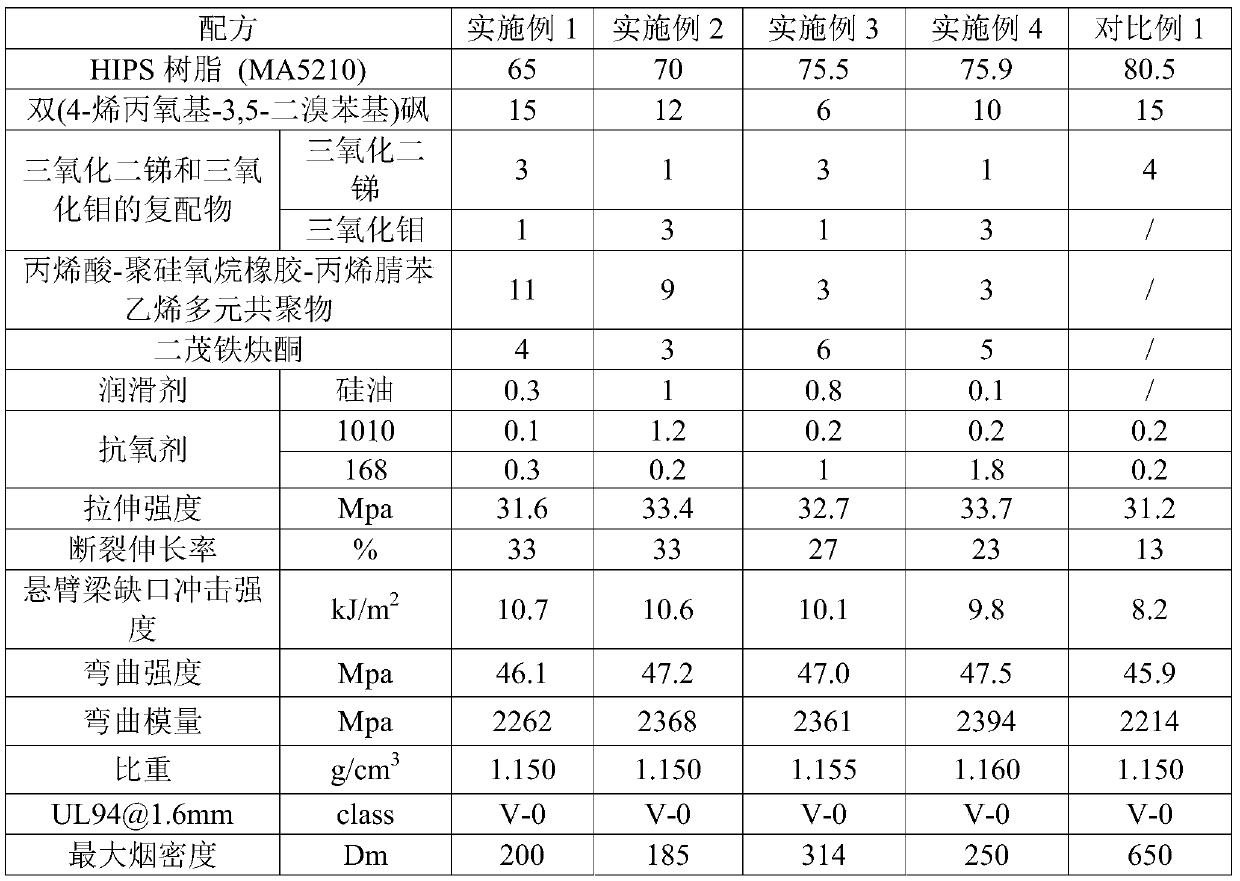

Embodiment 1

[0029]Example 1: Step 1: HIPS resin, bis(4-allyloxy-3,5-dibromophenyl) sulfone, compound of antimony trioxide and molybdenum trioxide, acrylic acid-polysiloxane Rubber-acrylonitrile styrene multi-polymer, ferrocene ketone, lubricant and antioxidant were added into a high-speed mixer according to the ratio and mixed to obtain a mixture. The mixing time was 10 minutes. The specific component distribution is shown in Table 1 . Step 2: Transport the mixture in step 1 to a twin-screw extruder for shearing and kneading to obtain a molten mixture, wherein the temperature of each section of the twin-screw extruder is 180°C, and the twin-screw extruder The length-to-diameter ratio is 30, and the screw speed is 600 rpm. Step 3: Extrude, granulate, and dry the molten mixture in step 2 to obtain a granular environmentally friendly low-smoke flame-retardant HIPS material. Step 4: Add the granular environment-friendly low-smoke flame-retardant HIPS material in step 3 into an injection mol...

Embodiment 2

[0030] Example 2: Step 1: HIPS resin, bis(4-allyloxy-3,5-dibromophenyl) sulfone, compound of antimony trioxide and molybdenum trioxide, acrylic acid-polysiloxane Rubber-acrylonitrile styrene multi-polymer, ferrocene ketone, lubricant and antioxidant were added into a high-speed mixer according to the ratio and mixed to obtain a mixture. The mixing time was 50 minutes. The specific component distribution is shown in Table 1 . Step 2: Transport the mixture in step 1 to a twin-screw extruder for shearing and kneading to obtain a molten mixture, wherein the temperature of each section of the twin-screw extruder is 220°C, and the twin-screw extruder The length-to-diameter ratio is 40, and the screw speed is 800 rpm. Step 3: Extrude, granulate, and dry the molten mixture in step 2 to obtain a granular environmentally friendly low-smoke flame-retardant HIPS material. Step 4: Add the granular environment-friendly low-smoke flame-retardant HIPS material in step 3 into an injection mo...

Embodiment 3

[0031] Example 3: Step 1: HIPS resin, bis(4-allyloxy-3,5-dibromophenyl) sulfone, compound of antimony trioxide and molybdenum trioxide, acrylic acid-polysiloxane Rubber-acrylonitrile styrene multi-polymer, ferrocenyl ketone, lubricant and antioxidant were added into a high-speed mixer according to the ratio and mixed to obtain a mixture. The mixing time was 30 minutes. The specific component distribution is shown in Table 1 . Step 2: Transport the mixture in step 1 to a twin-screw extruder for shearing and kneading to obtain a molten mixture, wherein the temperature of each section of the twin-screw extruder is 180°C, and the twin-screw extruder The length-to-diameter ratio is 40, and the screw speed is 500 rpm. Step 3: Extrude, granulate, and dry the molten mixture in step 2 to obtain a granular environmentally friendly low-smoke flame-retardant HIPS material. Step 4: Add the granular environment-friendly low-smoke flame-retardant HIPS material in step 3 into an injection m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com