Coating machine for exterior walls of high-rise buildings

A coating machine and building technology, applied in construction, building structure and other directions, can solve the problems of increasing the spraying cost of high-rise building facades, the safety of operators' lives, and the poor control of spraying quality, so as to improve the spraying range. , efficient and stable spraying, and the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

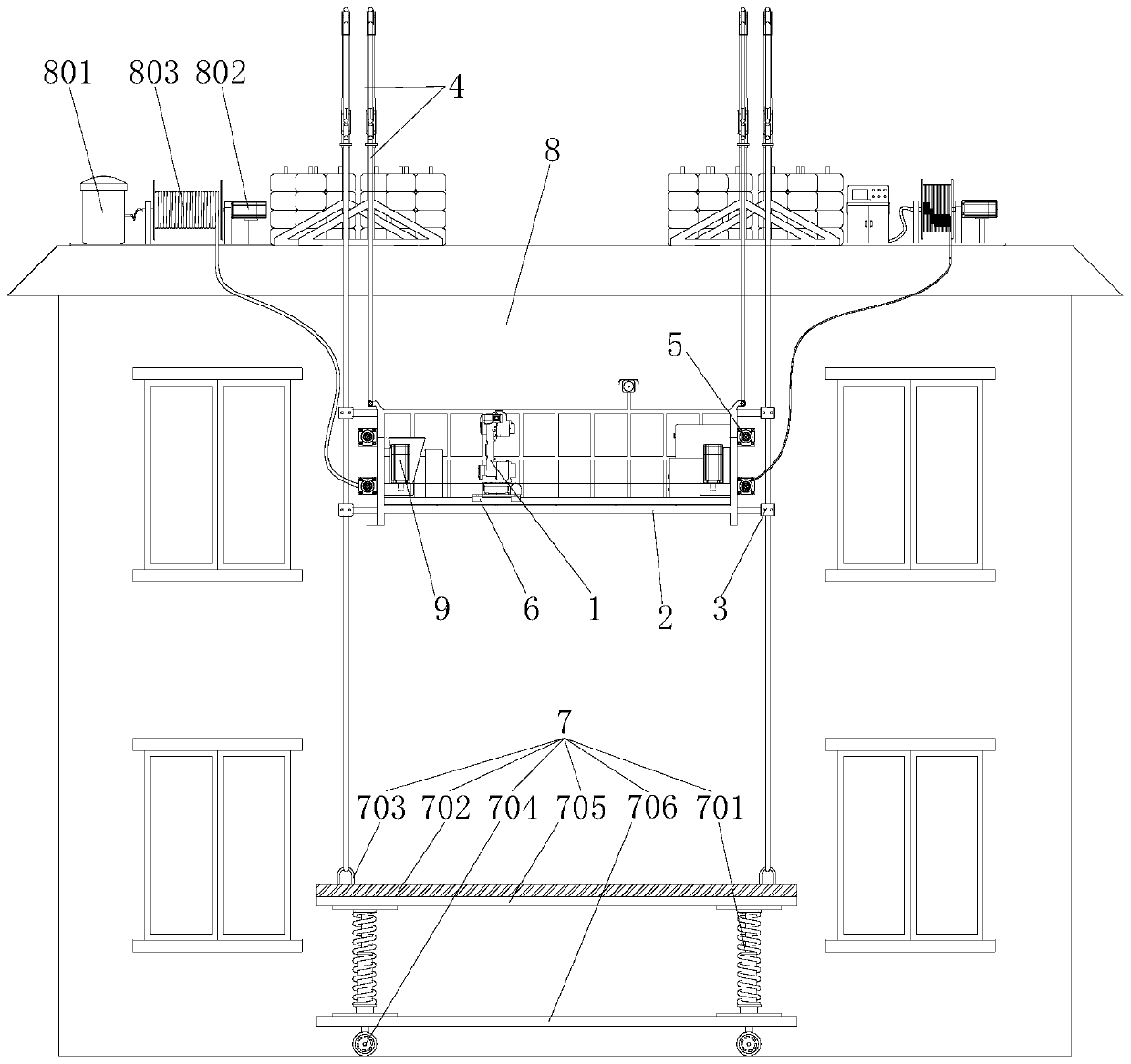

[0028] like Figure 1-5 As shown, this embodiment provides a high-rise building exterior wall coating machine, including a spraying robot 1, an electric hanging basket 2, a stall safety lock mechanism 3 and a suspension mechanism 4, and also includes a wall climbing mechanism 5, a spraying motion mechanism 6 and Anti-collision and shock-absorbing trolley 7, described spraying motion mechanism 6 is installed on the electric hanging basket 2, and spraying robot 1 is installed on the spraying motion mechanism 6, realizes the motion of spraying robot 1 on electric hanging basket 2 by spraying motion mechanism 6; Both ends of the electric hanging basket 2 are equipped with a wall climbing mechanism 5, and the electric hanging basket 2 is stably attached to the wall 8 through the wall climbing mechanism 5; the suspension mechanism 4, the electric hanging basket 2 and the anti- The shock-absorbing trolley 7 is arranged sequentially from top to bottom, the suspension mechanism 4 is co...

Embodiment 2

[0032] This embodiment is a further improvement made on the basis of Embodiment 1. The specific differences between this embodiment and Embodiment 1 are:

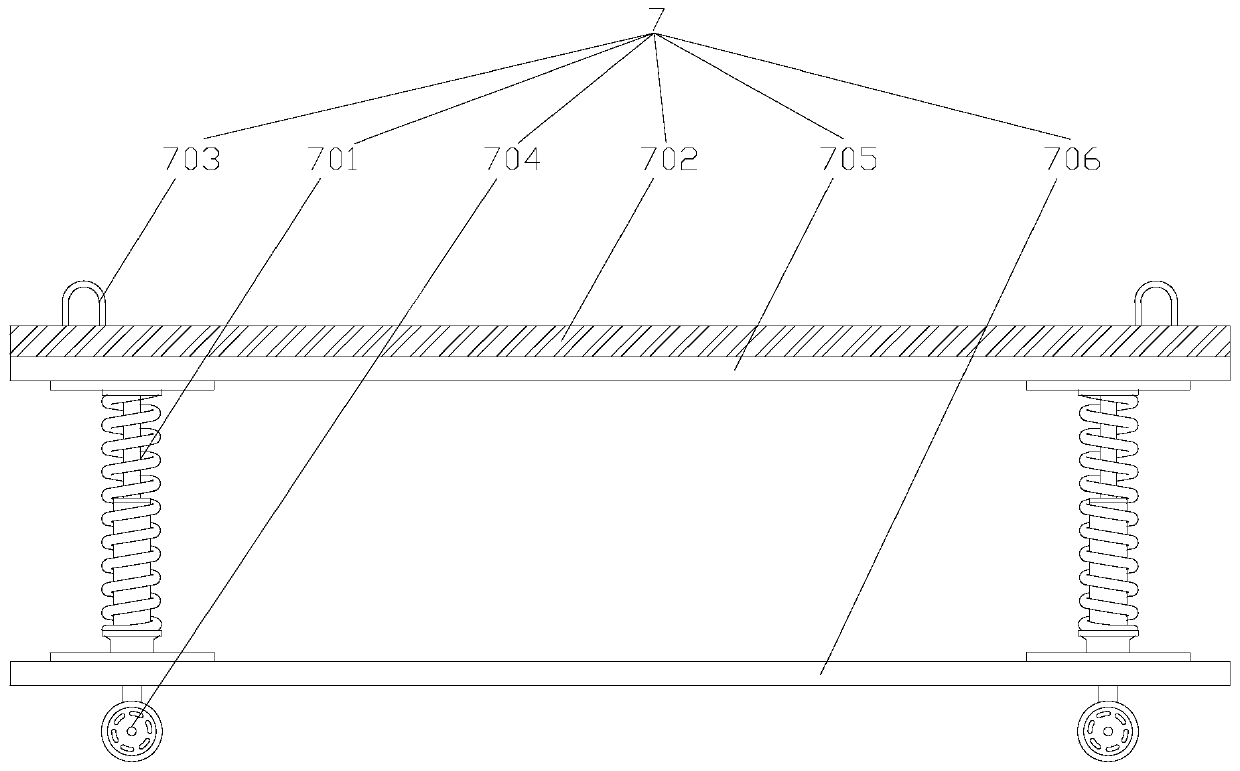

[0033] In this embodiment, it is further preferred that the anti-collision damping trolley 7 includes a shock absorbing damper 701, a buffer pad 702, a suspension ring 703, a pulley 704, an upper bottom plate 705 and a lower bottom plate 706 arranged in parallel, and the upper bottom plate 705 and the lower bottom plate The bottom plate 706 is connected by a plurality of shock-absorbing dampers 701 before, and the buffer pad 702 is arranged on the upper end of the upper bottom plate 705, and the upper end of the buffer pad 702 is provided with the suspension ring 703 correspondingly connected with the lower end of the first steel rope 401 one by one, The lower end of the lower bottom plate 706 is provided with a plurality of pulleys 704, which facilitates the movement of the anti-collision and shock-absorbing trolley 7. Of cou...

Embodiment 3

[0035] This embodiment is a further improvement made on the basis of Embodiment 1 or Embodiment 2. The specific differences between this embodiment and Embodiment 1 or Embodiment 2 are:

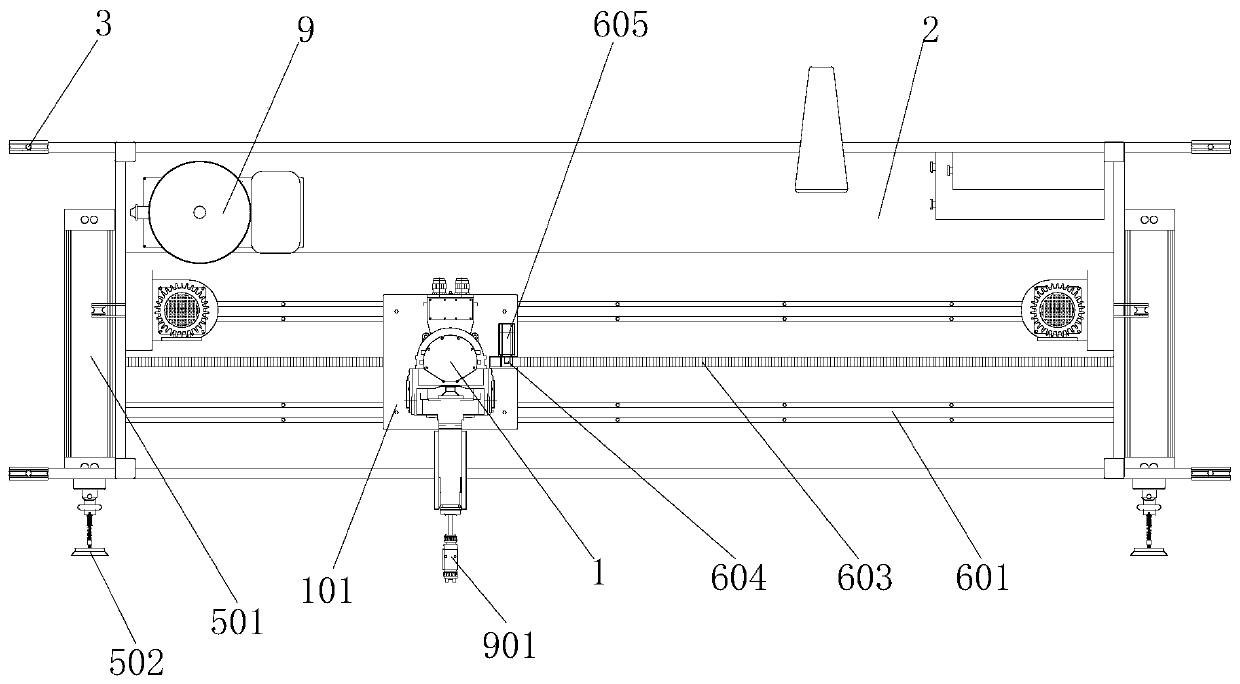

[0036] Further preferably in this embodiment, the spraying movement mechanism 6 includes a slide rail 601, a slide block 602, a rack 603, a gear 604 and a servo motor 605, the gear 604 is meshed with the rack 603, and each slide rail 601 The sliders 602 are all matched; two slide rails 601 arranged in parallel are installed on the electric hanging basket 2, and the rack 603 is installed on the electric hanging basket 2 between the two slide rails 601, and the rack 603 is parallel to the slide rail 601; the lower end of the spraying robot 1 is fixed with a base 101, and the slider 602 is installed on the lower end of the base 101; the servo motor 605 is fixed on the base 101, and the motor shaft of the servo motor 605 and the gear 604 For fixed connection, the gear 604 may not be directly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com