A dehydration and drying device for lily spice processing

A technology for dehydration drying and fragrance, which is applied in directions such as drying, drying machine, and drying gas arrangement, can solve the problems of poor effect, no pulverizing effect, low dehydration drying efficiency, etc., and achieves complete dehydration and drying. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

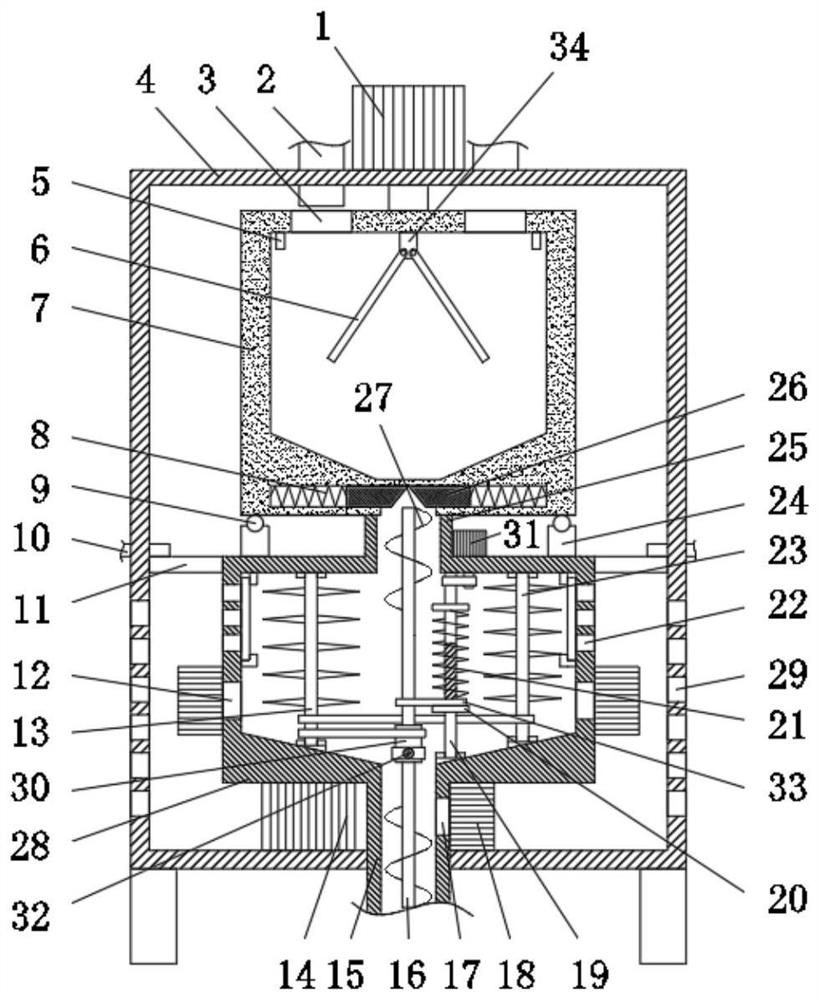

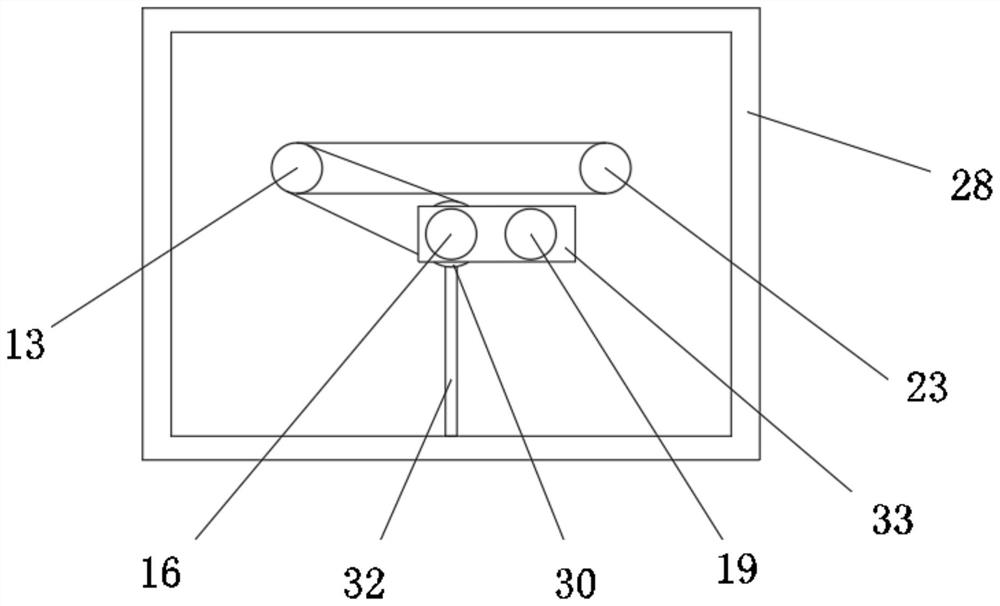

[0023]SeeFigure 1 ~ 3In the embodiment of the present invention, a dehydration drying apparatus for processing of a lilies, including the outer casing 4 and a dehydration drying mechanism disposed inside the outer casing 4, and the outer casing 4 is provided on the outer casing 4, the dehydration. The drying mechanism includes a pulverizing drying mechanism and a centrifugal dewatering mechanism disposed below the centrifugation mechanism, the pulverizing drying mechanism including a drying chamber 28 and a hot fan 18, the top of the drying chamber 28 passes The third lower material port 25 rotates, and is provided under the centrifugal dehydration mechanism, and the drying chamber 28 is rotated and provided having a first pulveroid shaft 13 and the first pulveroid shaft 13 and the second pulveroid shaft 23 are provided. The pulverized blade, the bottom of the drying chamber 28 fixedly mounted with the second drive motor 14, and the output terminal of the second drive motor 14 is fi...

Embodiment 2

[0034]In this example, further improvements performed on the basis of Example 1, compared to the first embodiment, the main difference is:

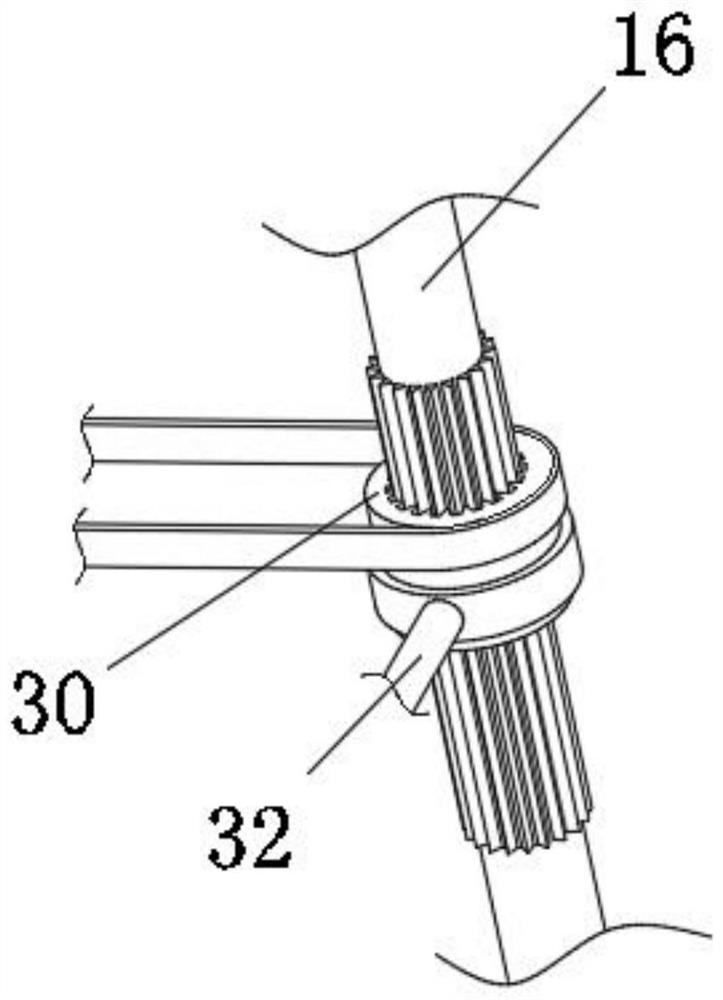

[0035]In the form of the conductive mechanism, in the present embodiment, it is preferable that the conductive mechanism includes a conductive shaft 16, a rotating block 30, and a stent 32, and the bracket 32 is fixedly mounted inside the drying chamber 28 and the stent 32 is fixedly mounted, and the rotating block 30 is disposed on the bracket 32 by the bearing and the rotating block 30 is arranged outside the conductive shaft 16, and the conductive shaft 16 is connected between the rotating block 30, two of the conductive shaft 16 The end is equipped with a scorpion 27, and the rotating block 30 and the first pulverizing shaft 13 are connected by a belt drive. The drying chamber 28 is rotated, and the rotating shaft 19 is provided, and the rotating shaft 19 is provided with a thread, and the rotating shaft 19 is located on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com