Charger pal shell cold forging stretching method and die

A stretching die and power bank technology, applied in the field of intelligent charging devices, can solve the problems of difficult processing, high manufacturing cost, and high product unit price, and achieve the effect of uniform molding and high stretching height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

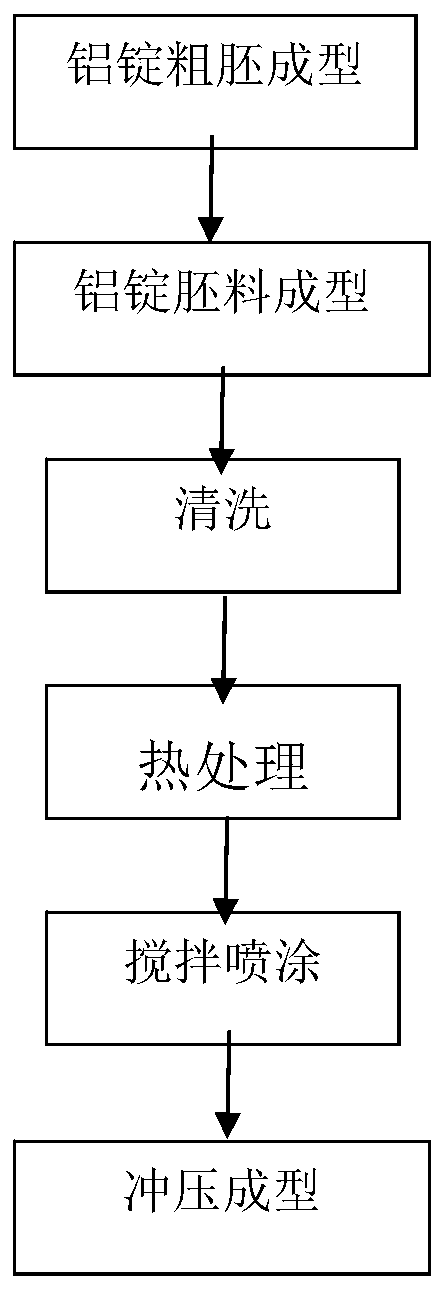

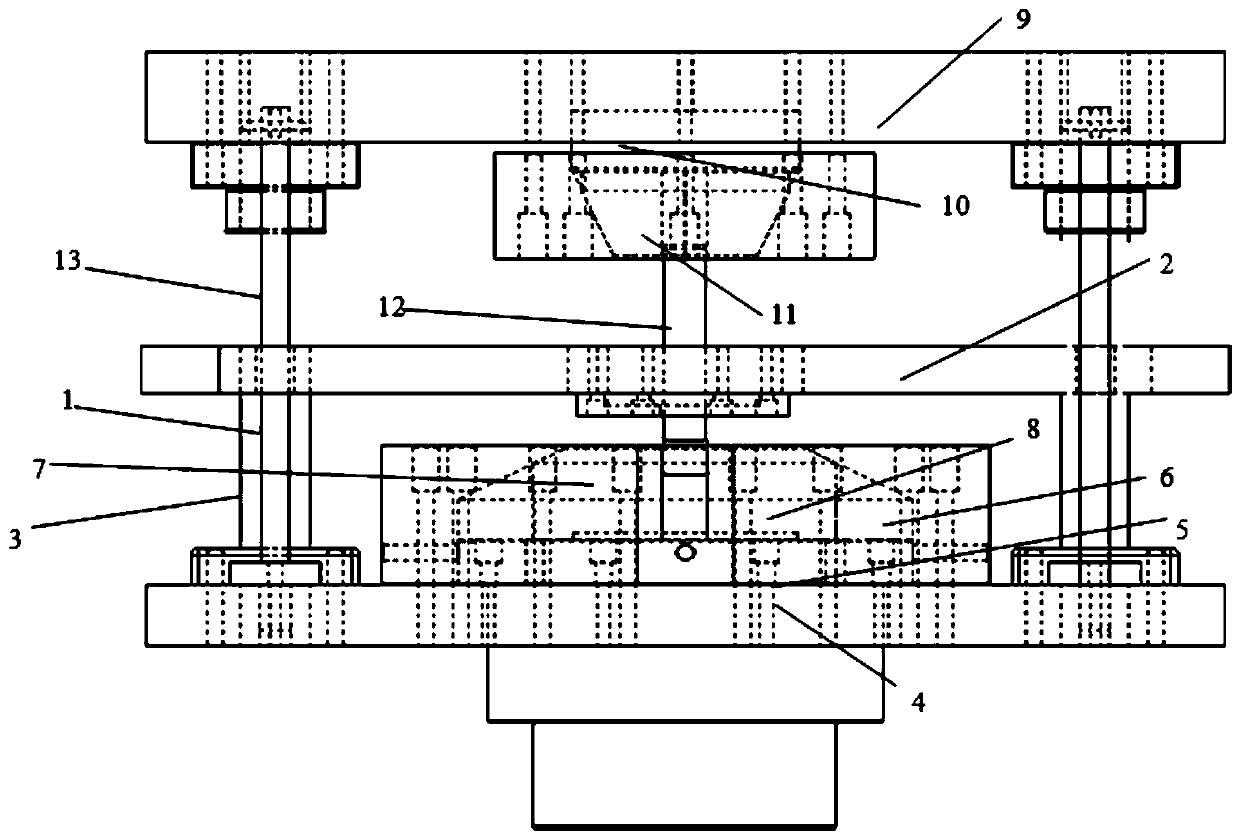

[0027] Such as figure 1 , figure 2 As shown, specific embodiment 1, a method for cold forging and stretching of a charging treasure shell, comprising the following steps:

[0028] S1: aluminum ingot rough blank forming: aluminum ingot rough blank is formed by aluminum extrusion;

[0029] S2: Aluminum ingot blank forming: use a cutting machine to cut the rough aluminum ingot in step S1 into columnar aluminum ingot blanks with a height of 32.5mm, a length of 74.8mm and a width of 21.3mm. The rough ingot is cut into aluminum ingot blank;

[0030] S3: Cleaning: Wash the drum for 20 minutes and rinse with clean water;

[0031] S4: heat treatment: conduct softening annealing heat treatment on the surface of the aluminum ingot blank, that is, dry it in a high-temperature electric furnace at 425°C and keep it warm for 5.5 hours, so that the state of the material is O state, that is, the hardness of the raw material is softened to the range of HV13-20 degrees.

[0032] S5: Stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com