Semi-automatic preparation equipment of short square tube boss for square tube frame of medical science popularization bulletin board

A technology of bulletin boards and tube frames, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inconsistent side lengths, large errors, and low work efficiency of the middle square hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

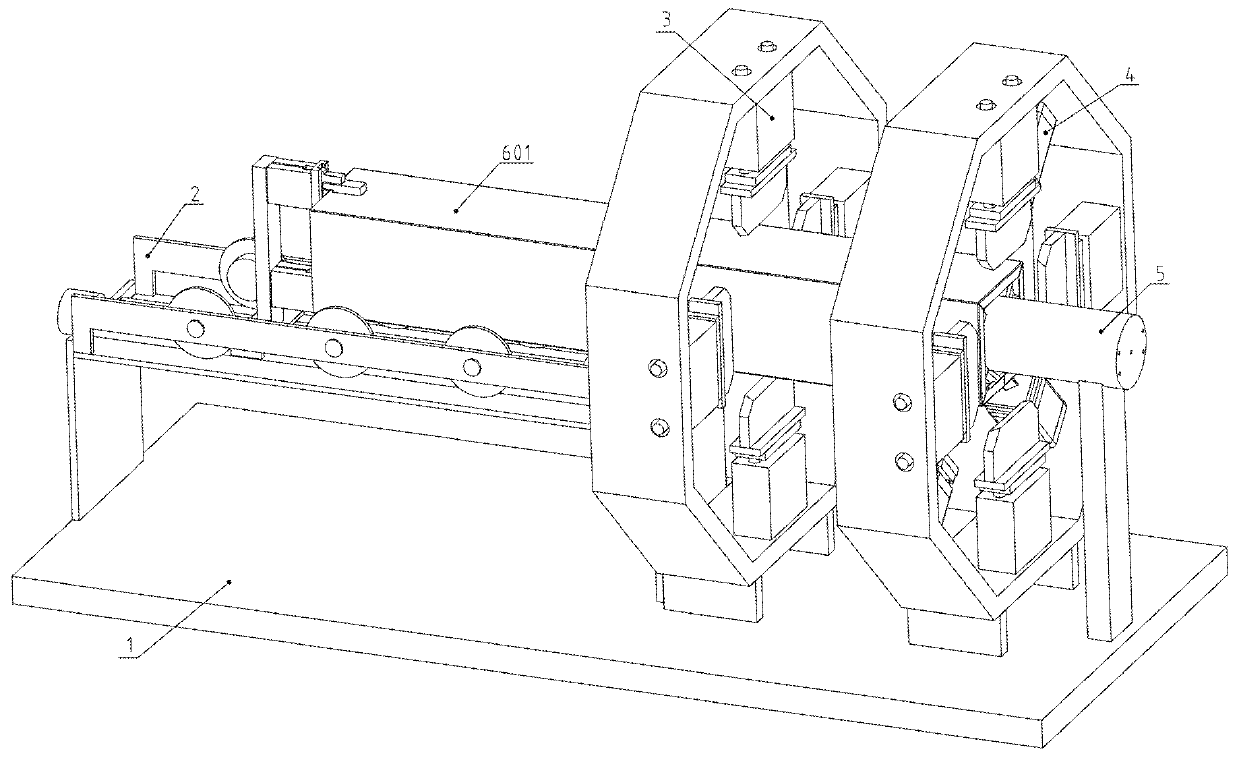

[0017] Example: see Figure 1 to Figure 24 .

[0018] A semi-automatic preparation equipment for the short square tube frame used in the square tube frame of the popular medical science bulletin board, including a frame 1, a conveying component 2, a shearing and rear bending component 3, a front bending and punching component 4, and a middle support component 5;

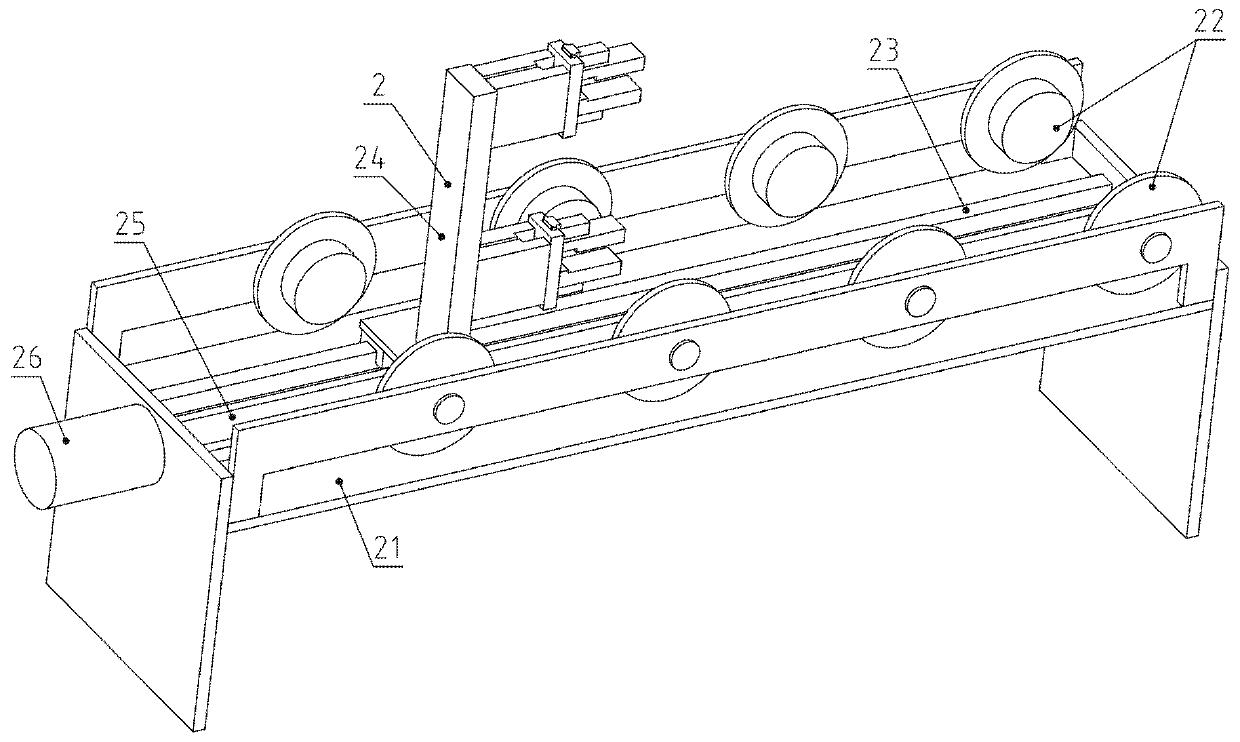

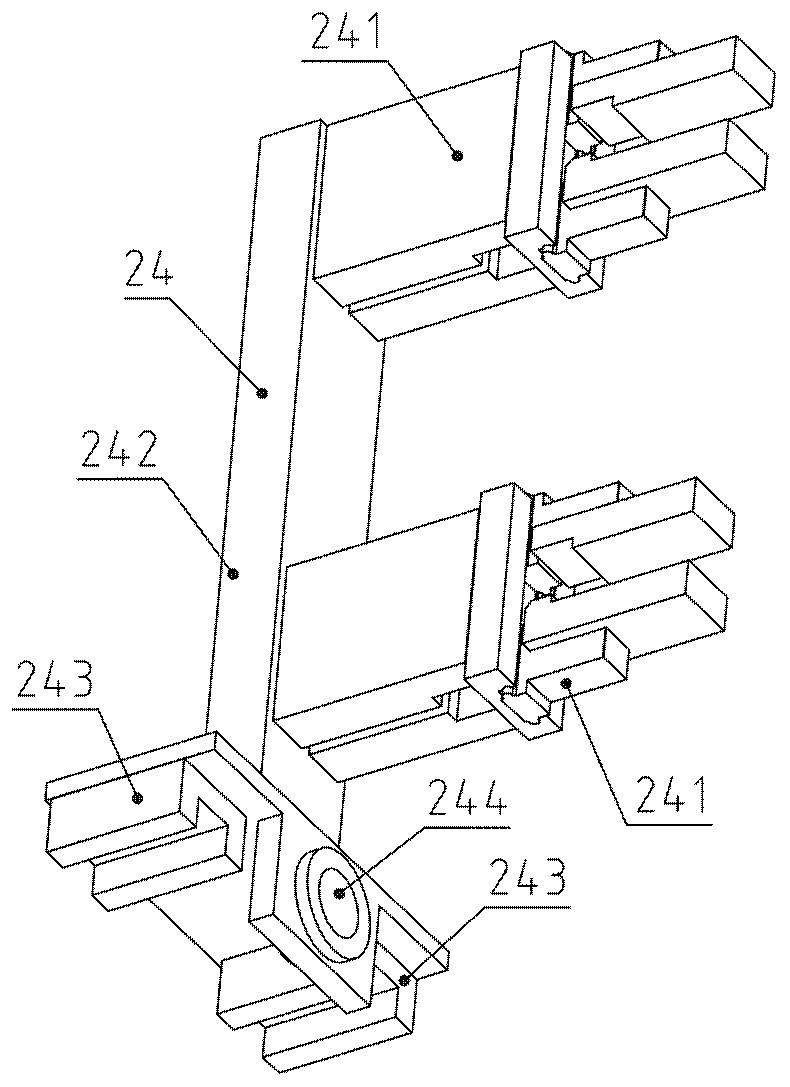

[0019] The conveying assembly 2 includes a conveying bracket 21, idlers 22, linear guide rails 23, conveying clamp assemblies 24, screw 25 and servo motor 26; the conveying bracket 21 is fixedly connected to the frame 1; the idler 22 is connected to the conveying bracket 21 through a rotating pair , the axis of rotation of the idler roller 22 is set along the left and right horizontal direction; the linear guide rail 23 is fixedly connected with the conveying support 21; the lead screw 25 and the conveying support 21 are connected through a rotating pair; the linear guide rail 23 and the lead screw 25 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com