Synthetic pine board and processing method thereof

A board processing method and pine wood technology are applied in the direction of wood processing appliances, pretreatment of molding materials, manufacturing tools, etc., which can solve the problems of complex processing technology, easy cracking and deformation, soft wood, etc., to save wood resources and resist large loads. Ability to solve the effect of large brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

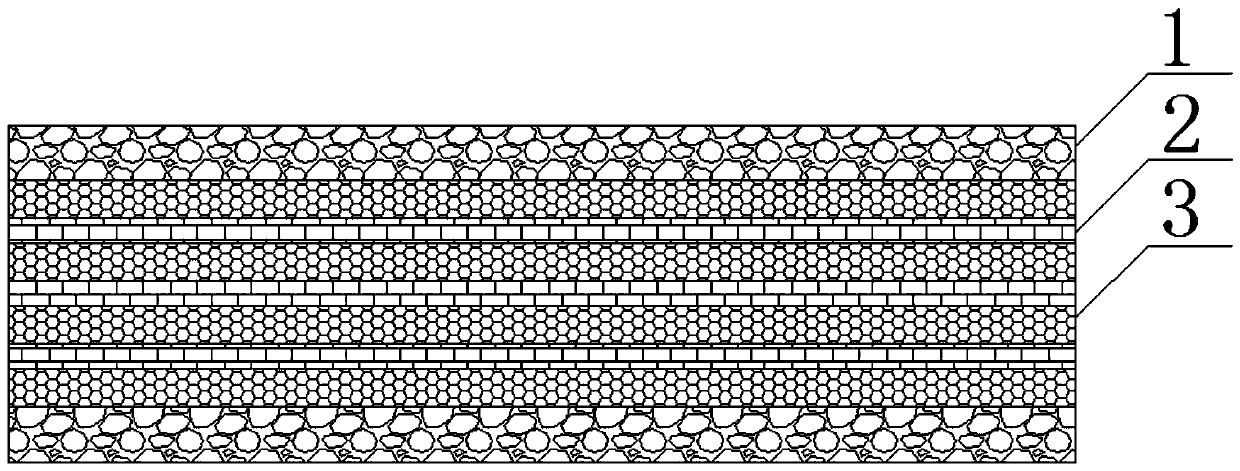

[0024] see figure 1 , a synthetic pine board, including a pine board 1 outside the board body, the thickness of the pine board 1 is 3-5 mm, the surface of the pine board 1 has good texture, no special treatment is required, only need to be polished, The texture is clear and beautiful, with good moisture resistance and corrosion resistance, and it is also a relatively environmentally friendly material. The pine board 1 itself has a unique fragrance, which maintains the natural color of the pine wood. There are multiple layers between the pine boards 1. Bamboo strip 2 and synthetic layer 3, the thickness of bamboo strip 2 is less than 2mm, which improves the toughness of the board and reduces t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com